Website:

REMBE® GmbH Safety+Control

Website:

REMBE® GmbH Safety+Control

Catalog excerpts

DATA SHEET KUB® Reverse acting rupture disc GBD-KUB-20173/1 | © REMBE® | All rights reserved | Valid from 02.11.2020 | Subject to technical changes without notice ENGINEERED TO LAST: ROBUST, HIGH PERFORMANCE, RUPTURE DISC SOLUTION Your advantages The KUB® is the only rupture disc to be manufactured using Euler's critical load formula to determine the burst pressure, creating the most robust, high-performance rupture disc available. Unlike other rupture disc solutions where a weak point is created in the metal, the KUB® is a unique, highly engineered solution, benefiting from a series of buckling pins which accurately collapse for reliable, full bore, opening. As there is no specific weak point on the rupture disc, the KUB® is an extremely robust solution, almost immune to damage by incorrect handling, improper installation or even being dropped! This maximises the lifespan of the disc and minimises long-term investment by lowering ongoing replacement costs. The KUB® features a two-layer design, with the smooth, unblemished surface of the sealing membrane facing the process minimising the possibility of damage due to corrosion. • irtually immune to damage during installation, transport or V storage – maximises process uptime and unnecessary replacement costs. Boasting a 98% operating ratio, the KUB® is not subject to fatigue even at higher operating pressures* and in the most demanding of process conditions in vapour, gas, liquid or two-phase applications. Unlike many other reverse acting discs, the unique construction of the KUB® makes it fully compatible with liquid-only applications, maximising installation points which can benefit from this rupture disc, simplifying customers' installation, maintenance and purchasing routines. • nique buckling pin element – creates the most robust rupture U disc design available. • einstall and reuse with ease after inspection – guarantees R maximum lifespan of one rupture disc, reducing spares costs. • Extend safety valve lifespan – robust design protects valves from process media, reducing corrosion risk and maximising overall investment. • idest size and burst pressure range in a single reverse acting W disc – one-disc type suitable for a wide range of process conditions, improving purchasing, inspection and maintenance routines. • Compatible with liquid-only applications – maximises installation points where the benefits of this technology can be achieved. *Depending on the specific application. REMBE® Innovation – unique in the market: The KUB® rupture disc has a robust design and can be removed, inspected, cleaned and reinstalled. Any damage is easy to detect with the naked eye. You can find detailed information and contact details for enquiries relating to KUB® at www.rembe.de. Give us a call on: T +49 2961 7405-0 or contact

Open the catalog to page 1

DATA SHEET Certification 0045 Works Certificate KOSHA (South Korea) Technical Data Product Parameters Feature Holder compatibility IG-KUB®; IG-KUB® V; IG-KUB®-PTU; G-KUB®; G-KUB® V; G-KUB®-PTU Signalling available NIMU, SIGU, BT-S, FOS, SB(-S), SGK, SBK-S Safety valve isolation Vacuum resistance Back pressure resistance Torque independent burst pressure Manufacturing design range [%] Operating ratio [%] Non-fragmenting design GBD-KUB-20173/1 | © REMBE® | All rights reserved | Valid from 02.11.2020 | Subject to technical changes without notice Leakrate [mbar l s-1] *for burst pressure > 1bar...

Open the catalog to page 2

DATA SHEET Burst Pressure Range (PED) Vent area Burst pressure Burst Pressure Range (ASME) GBD-KUB-20173/1 | © REMBE® | All rights reserved | Valid from 02.11.2020 | Subject to technical changes without notice Vent area Burst pressure

Open the catalog to page 3

DATA SHEET Material Specific Parameters Burst pressure SS/SS Material Specific Parameters GBD-KUB-20173/1 | © REMBE® | All rights reserved | Valid from 02.11.2020 | Subject to technical changes without notice Burst pressure Inc/Inc

Open the catalog to page 4

DATA SHEET Material Specific Parameters Burst pressure Inc/Has Material Specific Parameters Burst pressure SS/Ti 25 GBD-KUB-20173/1 | © REMBE® | All rights reserved | Valid from 02.11.2020 | Subject to technical changes without notice Material specific parameters should be considered in combination with the applicable certification. Due to different type testing requirements, deviations in technical parameters are possible. SS = Stainless Steel; Has = Hastelloy; Inc = Inconel; Ni = Nickel; Mo = Monel; Ti = Titanium; Ta = Tantalum Company Names or trademarks combined with material...

Open the catalog to page 5All REMBE® GmbH Safety+Control catalogs and technical brochures

-

PROCESS SAFETY

40 Pages

-

Explosion Safety

56 Pages

-

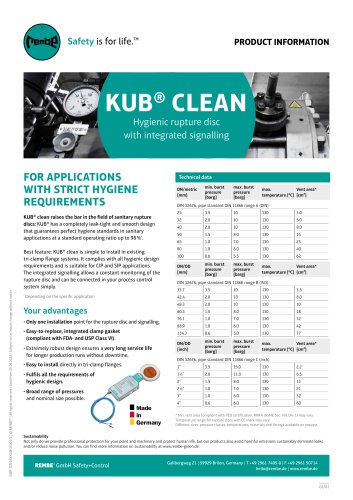

KUB® CLEAN

2 Pages

-

FARADO® I

2 Pages

-

SINGLE LAYER RUPTURE DISC

2 Pages

-

REMBE® PROCESS SAFETY

39 Pages

-

Explosion Venting ETX™

2 Pages

-

KUB® Product Information

3 Pages

-

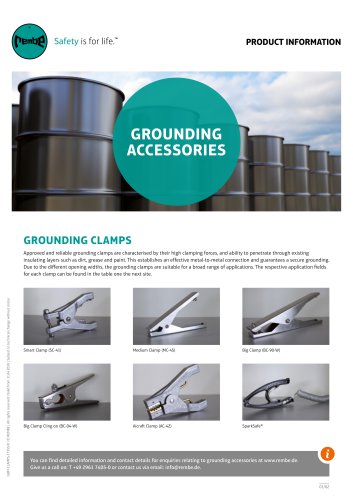

Grounding Accessories

2 Pages

-

Brochure Explosion Safety

40 Pages

-

Q-Box Product Information

2 Pages

-

FARADO Product Information

2 Pages

-

Q-Rohr Product Information

4 Pages

-

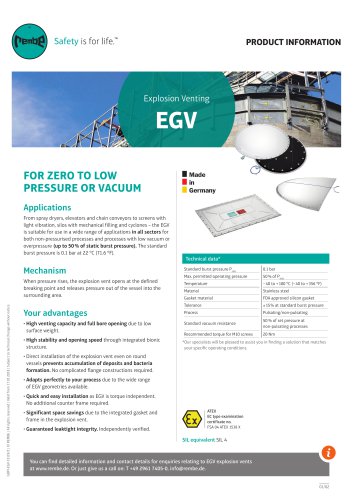

EGV Product Information

2 Pages

-

Rupture Disc Holder IG-HL

2 Pages

-

Rupture Disc Holder IG

3 Pages

-

CBS Product Information

1 Pages

-

SFD Product Information

1 Pages

-

STAR Product Information

1 Pages

-

ODV Product Information

4 Pages

-

IKB Product Information

2 Pages

-

KUB F Product Information

1 Pages

-

KUB V Product Information

1 Pages

-

KUB Product Information

3 Pages

-

EDP Product information

2 Pages

-

ODV+ODU Product Information

2 Pages

-

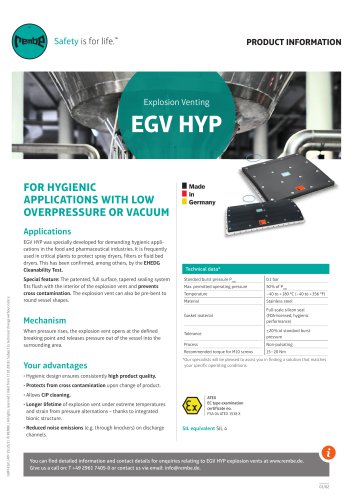

EGV HYP Product information

2 Pages