Website:

REMBE® GmbH Safety+Control

Website:

REMBE® GmbH Safety+Control

Catalog excerpts

PRODUCT INFORMATION Explosion Venting SELF-RECLOSING AND REUSABLE EXPLOSION DOOR Applications GBPI-ETX-19063/0 | © REMBE® | All rights reserved | Valid from 02.04.2019 | Subject to technical change without notice Drying processes in the food industry are often associated with the generation of explosive atmospheres. The applicaton of explosion protective systems is imperative, in particular due to the high probability-occurrence of glowing embers and hot surfaces. As a result of the function-related elongated design of ring dryers, post-explosion-fires in ring dryers are boosted by the so-called chimney effect, if the pressure relief devices remain open after an explosion. The REMBE® explosion door ETX™ prevents post-explosion-fires by self-reclosing after the explosion pressure has been relieved, thus preventing the supply of oxygen to the air. After successful relief the ETX™ will remain undamaged and will be ready for the next usage. Certified in accordance with Inspection certificate Mechanism The explosion door ETX™ is based on the air cushion principle. In the event of an explosion, the hinged lid will open extremely quickly, and will then be stopped by the integrated baffle plate. The integrated air cushion dampens the transmission of the kinetic energy to the rigid parts of the ETX™, and ensures that the lid of the ETX™ returns to its original, closed normal position after the explosion pressure has been relieved. Your advantages • Prevents chimney-effect related post-explosion-fires. • Self-reclosing. • Reusable. • High venting efficiency. • Trace heating to maintain a snow and ice freeness (optional). Autonomous safety device with trace heating, certified and type-examined according to ATEX 2014/34/EU You can find detailed information and contact details for enquiries relating to ETX™ at www.rembe.de. Give us a call on: T +49 2961 7405-0 or contact us via ema

Open the catalog to page 1

PRODUCT INFORMATIONFunction principle Explosion door closed ^ Baffle plate 3 Lid [A Locking device Explosion door open 3 Frame 3 Proximity switch Housing Gasket Burst pressure Standard vacuum resistance Dust explosion class Total weight Door lid weight Inner opening of the door body Geometric vent area: A Venting efficiency: bar*m*s-1 Effective vent area: AW Relief direction Maximum reduced explosion pressure Pred KG-Value Gas explosion class Static burst pressure Pstat Temperatures Autonomous safety device with trace heating, certified and type-examined according to ATEX 2014/34/EU 1.4404...

Open the catalog to page 2All REMBE® GmbH Safety+Control catalogs and technical brochures

-

PROCESS SAFETY

40 Pages

-

Explosion Safety

56 Pages

-

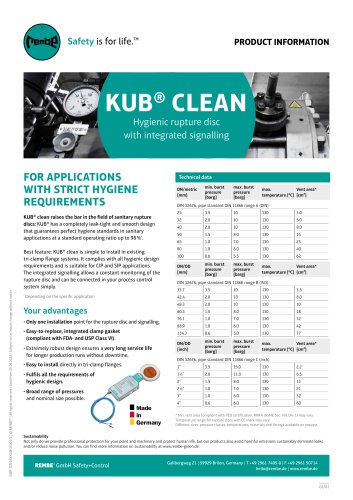

KUB® CLEAN

2 Pages

-

FARADO® I

2 Pages

-

SINGLE LAYER RUPTURE DISC

2 Pages

-

KUB®

5 Pages

-

REMBE® PROCESS SAFETY

39 Pages

-

KUB® Product Information

3 Pages

-

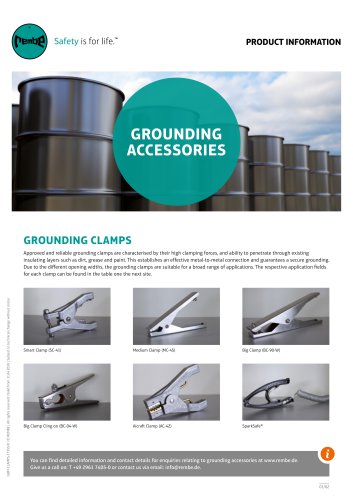

Grounding Accessories

2 Pages

-

Brochure Explosion Safety

40 Pages

-

Q-Box Product Information

2 Pages

-

FARADO Product Information

2 Pages

-

Q-Rohr Product Information

4 Pages

-

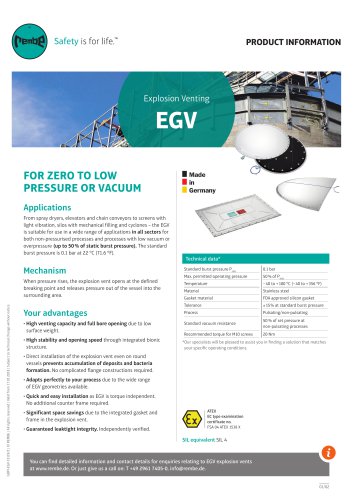

EGV Product Information

2 Pages

-

Rupture Disc Holder IG-HL

2 Pages

-

Rupture Disc Holder IG

3 Pages

-

CBS Product Information

1 Pages

-

SFD Product Information

1 Pages

-

STAR Product Information

1 Pages

-

ODV Product Information

4 Pages

-

IKB Product Information

2 Pages

-

KUB F Product Information

1 Pages

-

KUB V Product Information

1 Pages

-

KUB Product Information

3 Pages

-

EDP Product information

2 Pages

-

ODV+ODU Product Information

2 Pages

-

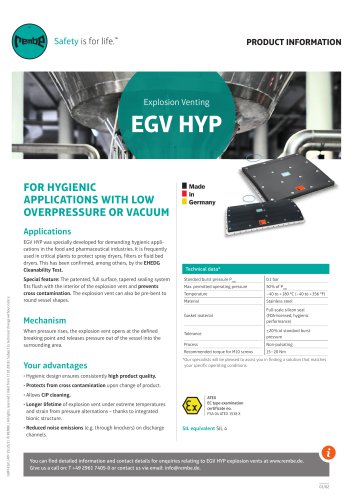

EGV HYP Product information

2 Pages