Website:

REMBE® GmbH Safety+Control

Website:

REMBE® GmbH Safety+Control

Catalog excerpts

REMBE® Explosion Safety Hazard oriented. Risk appropriate. Reliable. Sustainable. Authentic. Safe.

Open the catalog to page 1

Explosion Safety. From Humans. For Humans. Humans are what matter to us.

Open the catalog to page 2

At REMBE® we not only guarantee the suitable products, but above all comprehensive Explosion Safety solutions that always keep operational efficiency and the legal safety regulations firmly in mind. An economical and reliable solution tailored to your operational requirements. Crucial quality characteristics and the personal commitment make our Explosion Safety solutions the leaders in our industry. Our experienced consultants and engineers understand Explosion Safety as an engineering discipline. Challenge us and give us a chance – let‘s work together to increase health and safety at your...

Open the catalog to page 3

Principles of Explosion Safety. is the best REMBE® Product for your requirements? Deflagration Venting with Explosion Vents 13 | Product selection guide. 14 | EGV for zero to low pressure or vacuum. 15 | EDP for low to medium vacuum + pressure cycling. 16 | MDX for low burst pressures under high vacuum + pressure cycling. 17 | ODV, ODU for high to absolute vacuum + alternating pressure. 18 | EGV HYP for high to full vacuum + pressure cycling. 19 | ERO for hygienic applications with low pressure + pressure cycling. 20 | TARGO-VENT Add-on module to reduce the size of dangerous areas. 21 |...

Open the catalog to page 4

Explosion Isolation 33 | Product selection guide. 34 | EXKOP® System Space-saving, bidirectional isolation. 36 | Q-Flap RXTM Effectively isolated. 37 | VENTEX® Isolation with explosion safety valve. 38 | RSV Record closing times, flexible installation at any angle. 39 | REDEX® Slide Active isolation even at maximum explosion pressures. 40 | Q-BicTM Active isolation. 41 | Sustainable Explosion Safety begins with trust. Explosion Prevention 44 | CO.Pilot Combined CO-Detection and humidity measurement. 46 | Reliable monitoring of mobile tanks + trucks with FARADO® II, FARADO® II FIBC. 47 |...

Open the catalog to page 5

The Explosion-Pentagon: The requirements for a dust explosion. The Principles of Explosion Safety. When a combustible material, an ignition source and atmospheric oxygen collide in a confined space, the result is an explosion. Preventive explosion safety measures aim to stop this potentially lethal mixture from occurring. However, in practice, the vast number of potential ignition sources alone almost always makes this impossible. Consequently, the most important steps towards explosion safety for industrial companies are protection measures that minimise the damage caused by an explosion....

Open the catalog to page 6

The 3 key features of a modern protection concept 1. Reliability and productivity Protective systems must be permanently available and operational. The possibility of false triggers must be excluded as this reduces the productivity of the plant. 2. Compliance Modern protective systems must satisfy all legal requirements and thus guarantee legal compliance for plant operators. 3. Cost-effectiveness Protective systems must be as simple as possible to install and require minimum investment of time and financial resources. The total costs of ownership of the systems must also be kept as low as...

Open the catalog to page 7

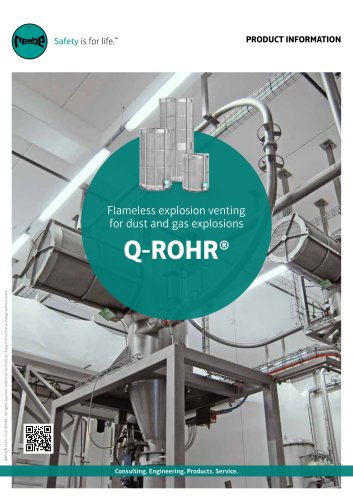

The stainless-steel mesh filter in the Q-Rohr®, Q-Box® and Q-Ball® flameless explosion venting devices protects the plant and surroundings from the effects of an explosion. Typical Applications for our Products. REMBE® explosion safety products are installed in a number of different industries and various plant locations. You can find a small selection of typical applications on this double page. Please note that industrial explosion safety does not Filter Dust collectors are used to capture dust, which is intentionally or unintentionally generated during the process. Therefore, an...

Open the catalog to page 8

Silos There is a particularly high risk during the filling of a silo through an explosive dust-air mixture. This is precisely the time frame with the highest likelihood of an explosion. In outdoor areas, silos are usually relieved with vent panels. Different types can be used depending on the filling process. Q-Box® or Q-Rohr® are installed for safe indoor venting. Explosion isolation is usually achieved through quench valves. These completely seal the pipes within a few milliseconds, thus inhibiting the explosion from propagating further. Elevators Elevators convey large amounts of...

Open the catalog to page 9

Which is the best REMBE® Product for your requirements? REMBE® is a specialist in protecting every area of your production plant. The best strategy for protecting your plant against explosions depends on the locations of the various plant components. Start in the middle and select the right protection system for your needs. Passenger traffic nearby Close to traffic routes and walkways located outdoors No passenger traffic nearby (safety distance of min. 20 m) TARGO-VENT + Explosion vent secure areas. Explosion Isolation EXKOP® System Space-saving, bidirectional isolation. Q-Flap RXTM...

Open the catalog to page 10

Q-Box® Perfect protection of the environment. Q-Ball® E, Q-Ball® S Effective + ultra-lightweight. Flameless venting Explosion suppression Well away from an external wall Passenger traffic nearby located indoors Close to an external wall (1-6 m) No passenger traffic nearby (safety distance of min. 20 m) Conventional explosion venting with explosion vents Explosion vents suitable for your application. Explosion vents + vent ducts divert the explosion to the outside.

Open the catalog to page 11

Deflagration Venting with Explosion vents. In the case of a deflagration, an explosion vent will rupture and thus protect the vessel by reducing the overpressure within it and releasing the explosion into the surrounding environment in a controlled manner. Industrial processes vary widely depending on the sector and the product. No two processes are identical. For this reason, REMBE® supplies explosion vents in a variety of different shapes, materials, temperature and pressure resistances and many other specifications. Advantages ✓ Easy to install. ✓ No maintenance required. ✓ Long service...

Open the catalog to page 12All REMBE® GmbH Safety+Control catalogs and technical brochures

-

PROCESS SAFETY

40 Pages

-

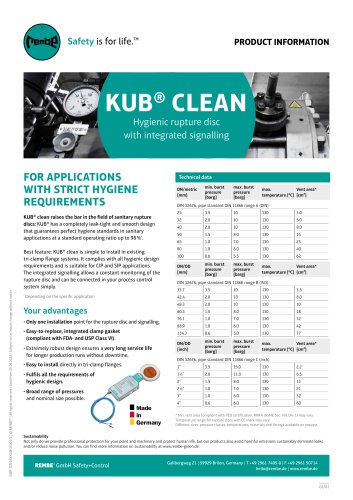

KUB® CLEAN

2 Pages

-

FARADO® I

2 Pages

-

SINGLE LAYER RUPTURE DISC

2 Pages

-

KUB®

5 Pages

-

REMBE® PROCESS SAFETY

39 Pages

-

Explosion Venting ETX™

2 Pages

-

KUB® Product Information

3 Pages

-

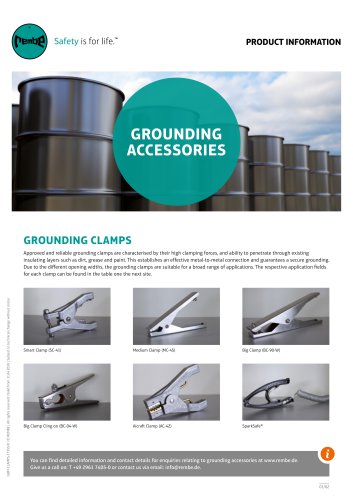

Grounding Accessories

2 Pages

-

Brochure Explosion Safety

40 Pages

-

Q-Box Product Information

2 Pages

-

FARADO Product Information

2 Pages

-

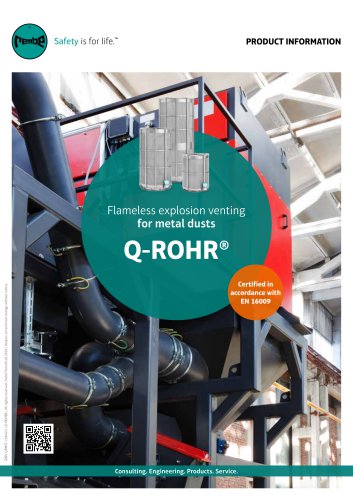

Q-Rohr Product Information

4 Pages

-

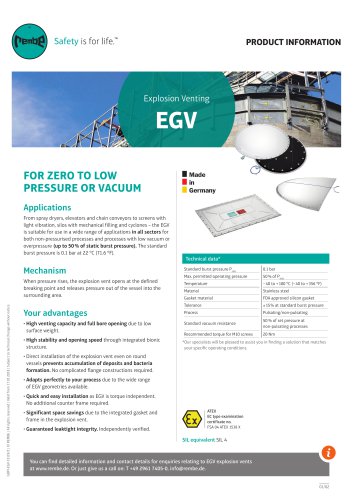

EGV Product Information

2 Pages

-

Rupture Disc Holder IG-HL

2 Pages

-

Rupture Disc Holder IG

3 Pages

-

CBS Product Information

1 Pages

-

SFD Product Information

1 Pages

-

STAR Product Information

1 Pages

-

ODV Product Information

4 Pages

-

IKB Product Information

2 Pages

-

KUB F Product Information

1 Pages

-

KUB V Product Information

1 Pages

-

KUB Product Information

3 Pages

-

EDP Product information

2 Pages

-

ODV+ODU Product Information

2 Pages

-

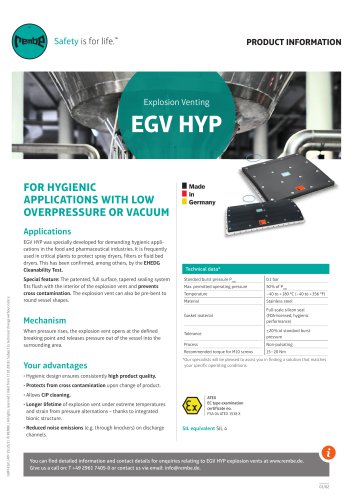

EGV HYP Product information

2 Pages