Website:

REMBE® GmbH Safety+Control

Website:

REMBE® GmbH Safety+Control

Catalog excerpts

Consulting. Engineering. Products. Service

Open the catalog to page 1

Dear Customer and Partner, Over the last five years, REMBE® has built a team of experts in the field of explosion safety that is unmatched among other manufacturers. We are no longer just a manufacturer of products and components but a consultancy, engineering house and a full service provider. We deliver turn-key explosion safety concepts all over the world, for all delicate or complex applications, and in a variety of in ustries including aerospace, cosmetics, chemicals, foodstuffs, d pharmaceuticals, biotech, energy, timber, infrastructure, transport and more. To guarantee REMBE® quality...

Open the catalog to page 2

Francesca Vincenzi is an engineering specialist in explosion safety who has no issues getting her hands dirty when inspecting an industrial site. She has more than 10 years experience as a consultant in the Italian food, pharmaceuticals and timber industries. Since joining REMBE® in 2012, Francesca has expanded her scope to include Europe and North America, and since 2014 she has been a Senior Consultant in Explosion Safety. This position covers full-spectrum safety scans for medium- and large-scale factories. Her customers respect her comprehensive and competent safety concepts, her broad...

Open the catalog to page 3

THE PRINCIPLES OF EXPLOSION SAFETY Why do explosions occur? When a combustible material, an ignition source and atmospheric oxygen collide in a confined space, the result is an explosion. Preventative explosion safety measures aim to stop this potentially lethal mixture from occurring. However, in practice, the vast number of potential ignition sources alone almost always makes this impossible. Consequently, the most important steps towards explosion safety for industrial companies are protection measures that minimise the damage caused by an explosion. Industrial plants must always be...

Open the catalog to page 4

The 3 key features of a modern safety concept 1. R eliability and productivity: Protective systems must be permanently available and operational. The possibility of false triggers must be excluded as this reduces the productivity of the plant. C ompliance: Modern protective systems must satisfy all legal requirements and thus guarantee legal compliance for plant operators. Why is explosion safety so crucial? C ost-effectiveness: Protective systems must be as simple as possible to install and require minimum investment of time and financial resources. The total costs of ownership of the...

Open the catalog to page 5

SAFETY IS FOR Our mission: your safety. Operational safety is an important responsibility. In fact, it’s a mission to which we have dedicated ourselves wholeheartedly for over 45 years now. Throughout the world our experts have a single aim – to provide the best possible protection for your systems and processes. You’ll benefit from our decades of experience which ensures that you always receive an honest analysis and products of the highest quality. Working diligently and responsibly, our attention is fully focused on the customised optimisation of your routines, manufacturing processes...

Open the catalog to page 6

LIFE. A decision for REMBE® means opting for perfect safety. As an independent, medium-sized, German company we supply products Made in Germany – a further bonus for your safety. Moreover, you will always have the support of our experts in matters of explosion safety and pressure relief – 24/7, all the year round. It is our promise! Our products are not just excellent. They are approved and certified. Downtime costs money. Our service never stands still – throughout the world. Good is never good enough for us. So we keep putting ourselves on the test bench. The result is safety products...

Open the catalog to page 7

Selection guide WHICH IS THE BEST REMBE® PRODUCT FOR YOUR REQUIREMENTS? REMBE® is a specialist in protecting every area of your production plant. The best strategy for protecting your plant against explosions depends on the locations of the various plant components. Start in the middle and select the right protection system for your needs. TARGO-VENT + Explosion vent Add-on module for explosion vents to reduce the size of hazardous areas (p. 22) Close to traffic routes and walkways Passenger traffic nearby Located outdoors No passenger traffic nearby (safety distance of min. 20 m) Explosion...

Open the catalog to page 8

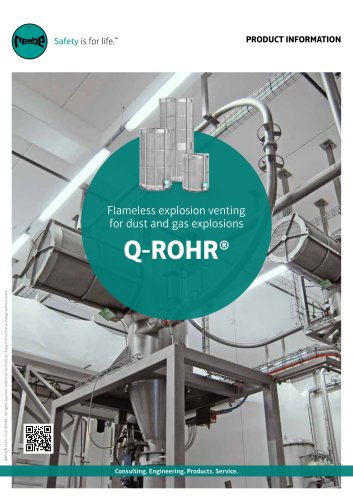

Q-Rohr® Flameless venting of dust and gas explosions (p. 26) Q-Box Cost-effective indoor explosion venting of dust explosions (p. 28) Q-Bic™ Explosion suppression, also for toxic and pharmaceutical substances Flameless explosion venting / explosion suppression * Well away from an external wall Passenger traffic nearby Located indoors Close to an external wall (1 – 6 m) No passenger traffic nearby (safety distance of min. 20 m) START Find the optimum explosion protective system for your entire plant and vessels such as silos, filters, cyclones, separators, mixers, dryers, etc. Conventional...

Open the catalog to page 9

Typical Applications Typical Applications for our Products REMBE® explosion safety products are installed in a number of different industries and various plant locations. You can find a small selection of typical applications on this double page. Please note that industrial explosion safety does not follow a standard recipe, but requires a thorough analysis of the installation. We will gladly support you in that respect. Give us a call on: T +49 2961 7405-0 or contact us via email: info@rembe.de Filter Dust collectors are used to capture dust, which is intentionally or unintentionally...

Open the catalog to page 10

The stainless steel mesh filter of the Q-Rohr® and Q-Box flameless vents protects installations and their surroundings from the impact of an explosion. Elevators Elevators convey large amounts of (combustible) bulk materials, and thus pose a high risk for an explosion. The size and strength of the bucket elevator determine the number and mounting distance for the required protective systems, depending on the bulk material involved. Outdoor elevator shafts are commonly protected with vent panels (as of p. 12), where as Q-Box are applied indoors (p. 28). A combination of conventional and...

Open the catalog to page 11All REMBE® GmbH Safety+Control catalogs and technical brochures

-

PROCESS SAFETY

40 Pages

-

Explosion Safety

56 Pages

-

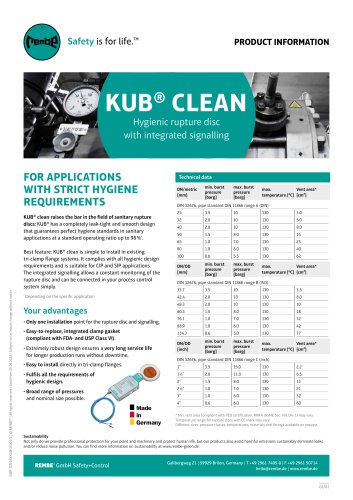

KUB® CLEAN

2 Pages

-

FARADO® I

2 Pages

-

SINGLE LAYER RUPTURE DISC

2 Pages

-

KUB®

5 Pages

-

REMBE® PROCESS SAFETY

39 Pages

-

Explosion Venting ETX™

2 Pages

-

KUB® Product Information

3 Pages

-

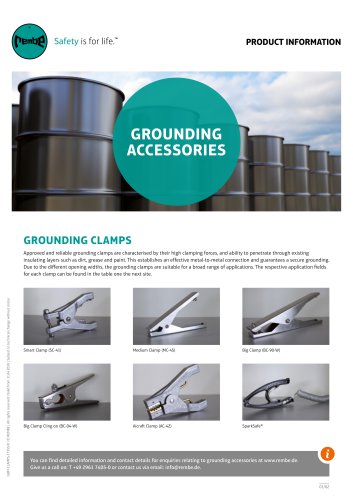

Grounding Accessories

2 Pages

-

Q-Box Product Information

2 Pages

-

FARADO Product Information

2 Pages

-

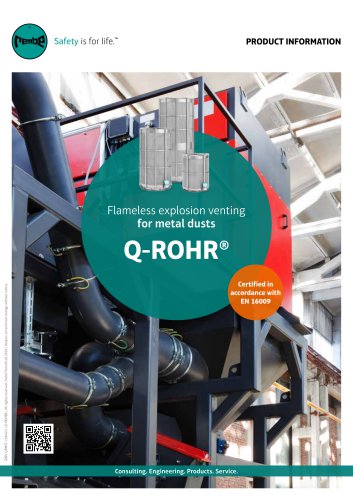

Q-Rohr Product Information

4 Pages

-

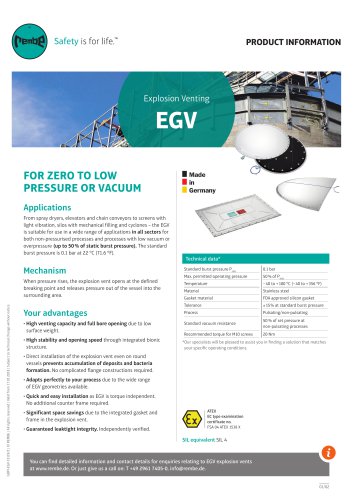

EGV Product Information

2 Pages

-

Rupture Disc Holder IG-HL

2 Pages

-

Rupture Disc Holder IG

3 Pages

-

CBS Product Information

1 Pages

-

SFD Product Information

1 Pages

-

STAR Product Information

1 Pages

-

ODV Product Information

4 Pages

-

IKB Product Information

2 Pages

-

KUB F Product Information

1 Pages

-

KUB V Product Information

1 Pages

-

KUB Product Information

3 Pages

-

EDP Product information

2 Pages

-

ODV+ODU Product Information

2 Pages

-

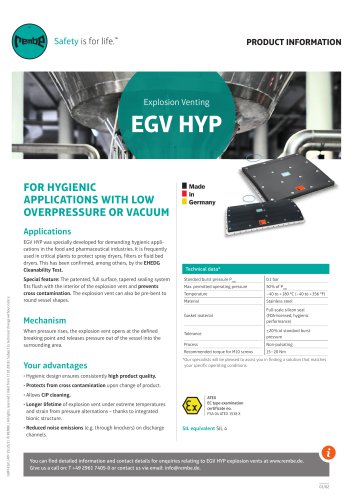

EGV HYP Product information

2 Pages