Catalog excerpts

Styrene Classification and Labelling March 23, 2012 A. Piccinotti

Open the catalog to page 1

Presentation Goals • To offer an objective and science based view of actual styrene regulatory status in Europe t h r o u g h • REACH and CLP fundamentals • Styrene Producer Association (SPA) and Cefic UPR Sector Group Position and activity • Styrene Classification Process and Timing 2

Open the catalog to page 2

Styrene and REACH • REACH legislation has been in force since June 2007. • The main aim of REACH is to ensure the safe use of chemicals for workers, consumers and the environment. • REACH puts the responsibility on industry and imposes obligations on all parties in the supply chain. • European Styrene manufacturers/importers have registered Styrene and have started to send out the new extended Safety Data Sheet (eSDS). • Styrene Extended SDS include Exposure Scenarios (ES) for manufacture of UP/VE resins and formulated resins, and FRP manufacturing in industrial and professional settings.

Open the catalog to page 3

Globally Harmonized System (GHS) for Classification and Labelling of Chemicals • GHS for hazardous substances and mixtures is being introduced worldwide. • GHS was implemented in Europe in 2008 by means of the Classification, Labelling and Packaging (CLP) of substances and mixtures regulation. • CLP introduces revised criteria for hazard classification, new guidelines for safety data sheets, product labels and transport information. • As a result of REACH and CLP, industry has now entered the phase in which new information must be provided to downstream users. 4

Open the catalog to page 4

Styrene Producer Association (SPA) Position • The SPA, organized in the REACH Styrene consortium, proposed a self-classification for Styrene which resulted in additional risk phrases and hazard statements. • New risk phrases from the Styrene registration dossier on top of Directive 67/548/EEC Annex I: – R48/20 - harmful: danger of serious damage to health by prolonged exposure through inhalation – R65 - harmful: may cause lung damage if swallowed • New hazard statements from the styrene registration dossier on top of CLP Annex VI: – H372: Causes damage to hearing through prolonged or...

Open the catalog to page 5

Classification and Labeling of Resins • As most of UP/VE resins are mixtures containing greater than 10% Styrene, this new classification of Styrene will be directly applied to the classification of UP/VE resins. • European resin manufacturers are updating their SDS to reflect these changes in Styrene classification. – http://www.upresins.org/upload/documents/webpage/styrene-position-paperen.pdf • Resin manufacturers will continue to specify risk management measures and operating conditions for safe use of Styrene in UP/VE resin manufacturing and FRP manufacturing in industrial and...

Open the catalog to page 6

Styrene DNELs • The REACH Styrene consortium proposed Derived No Effect Levels (DNELs) for worker inhalation exposure: – 20 ppm as an 8-hour time-weighted average (TWA) • A DNEL is a threshold for safe use of substances and serves as the basis for developing exposure scenarios. • The REACH Styrene consortium and Cefic UPR Sector Group used the DNELs and ECETOC TRA to perform safe use analyses of UPR/VER manufacturing and use. • DNELs may ultimately be used for harmonisation of Occupational Exposure Limits (OELs) across the EU: – The timing for this process is not yet determined – Harmonized...

Open the catalog to page 7

Styrene Exposure Scenario Results • Styrene exposure during manufacture of UPR, VER, and formulated resins is “safe” under typical conditions of use. • FRP manufacturing in an industrial setting is also “safe,” but requires careful attention to workplace ventilation. • FRP manufacturing in a professional setting requires respiratory protection in most cases to ensure “safe” use of styrene. • Dermal route does not contribute significantly to overall risk.

Open the catalog to page 8

Styrene OELs • Currently, Styrene 8-hour TWA limits in the EU vary depending upon the country. • The exposure scenarios prove that workers can work safely with Styrene-containing resins when using recommended protective equipment and by limiting possible exposure to emissions. • Extended safety data sheets and Cefic UP/VE Resin Safe Handling Guides (Safe Handling Guides :: The European UP/VE Resin Association) provide relevant information on best practices, operating conditions and risk management measures to control exposure. • The U.S. Styrene Information & Research Center (SIRC) also...

Open the catalog to page 9

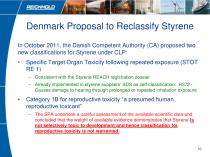

Denmark Proposal to Reclassify Styrene In October 2011, the Danish Competent Authority (CA) proposed two new classifications for Styrene under CLP: • Specific Target Organ Toxicity following repeated exposure (STOT RE 1) – Consistent with the Styrene REACH registration dossier – Already implemented in styrene suppliers’ SDS as self-classification: H372 Causes damage to hearing through prolonged or repeated inhalation exposure Category 1B for reproductive toxicity “a presumed human reproductive toxicant” – The SPA undertook a careful assessment of the available scientific data and concluded...

Open the catalog to page 10

What was the previous conclusion on Styrene reproductive toxicity? • The current Danish proposal does not bring forward any new scientific information. • Denmark made the same proposal during the TC C&L review in 2007 based on the same studies. • The majority of EU Member States agreed with the UK Rapporteur that the data was not sufficient for any classification for reproductive toxicity. • The UK, as previous Member State rapporteur for Styrene, did not make a new proposal for classification and labelling in 2008 based on extensive review of available data. • Styrene is not classified as...

Open the catalog to page 11

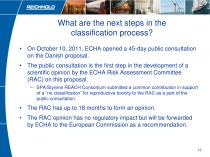

What are the next steps in the classification process? • On October 10, 2011, ECHA opened a 45-day public consultation on the Danish proposal. • The public consultation is the first step in the development of a scientific opinion by the ECHA Risk Assessment Committee (RAC) on this proposal. – SPA/Styrene REACH Consortium submitted a common contribution in support of a “no classification” for reproductive toxicity to the RAC as a part of the public consultation. • The RAC has up to 18 months to form an opinion. • The RAC opinion has no regulatory impact but will be forwarded by ECHA to the...

Open the catalog to page 12All Reichhold catalogs and technical brochures

-

UROTUF® F275-M-75

2 Pages

-

EPOTUF® 38-698

2 Pages

-

F600-W-40

2 Pages

-

UROTUF®

7 Pages

-

DION® IMPACT 9133

2 Pages

-

UROTUF® Water-borne Urethane

4 Pages

-

BioiPreferred® Guideline

2 Pages

-

NORPOL® ULTIMATE GELCOAT

2 Pages

-

NORPOL® SVX Gelcoat

2 Pages

-

NORPOL® SVG Gelcoats

3 Pages

-

NEW NORPOL® SRG GELCOAT

2 Pages

-

DION® Corrosion Guide

45 Pages

-

POLYLITE ® 3354225

3 Pages

-

EPOTUF® 38-698

2 Pages

-

Improved vinyl ester technology

21 Pages

-

UROTUF® F600-W-40

2 Pages

-

UROTUF® E300-W-40

2 Pages

-

Corrosion Guide

45 Pages

-

Coating Resins Catalog

35 Pages

-

BECKOSOL AQ®

12 Pages

-

AROFLINT® Flyer

2 Pages

-

Material Selection Guide

77 Pages

-

FRP Inspection Guide

36 Pages

-

Vacuum Foil Infusion

19 Pages

-

RTM Light

15 Pages

-

Pultrusion (Europe)

3 Pages

-

A Reichhold Company Overview

11 Pages

-

NORPOL® VBC Barriercoat

3 Pages

-

NORPOL® GI

3 Pages

-

NORPOL® CPG

4 Pages

-

Pultrusion (EMEA)

3 Pages

-

NORPOL® SVG Gelcoats

4 Pages

-

Fire Retardant (EMEA)

15 Pages

-

Bonding Paste (EMEA)

15 Pages

Archived catalogs

-

Vacuum Foil/ RTM Process (EMEA)

11 Pages

-

Tooling System (EMEA)

11 Pages

-

SMC/ BMC (EMEA)

3 Pages