Novel Vinyl Hybrid resin technology meet demanding performance and environmental requirements in Automotive

27Pages

Catalog excerpts

Novel Vinyl Hybrid resin technology meet demanding performance and environmental requirements in Automotive Jim Bono JEC Paris, March 12th, 2014

Open the catalog to page 1

Background • Advanced Material Market • Styrenated Systems are Unacceptable – Governmental Regulations – Control Technologies Needed – Minimize Capital Investment • Development Need for Reactive Diluent Free Thermoset Resin Systems – Cost Effective – Improved Dry/ Wet Tg – Improved Production Rates- approach 3 minute cycle

Open the catalog to page 2

Nomenclature Styrene Free Resins Reactive Diluent Free Solids: “Pre-preg Monomer Free Hot Melt Vinyl Hybrids” Alternative Reactive Diluents Liquids: Reactive Oligomers “Vinyl Hybrid Liquid Resins” VT • Acrylates • Others

Open the catalog to page 3

Chemistry Description: Vinyl Hybrids • ADVALITE™ – Monomer Free Hot Melts • ADVALITE™ – Vinyl Hybrid Liquid Resins

Open the catalog to page 4

Application Overview Process Applications: • Infusion • RTM • Closed Mold • Filament Winding • Pultrusion Uses standard catalysts and initiators – processes the same as UPR and Vinyl Ester resins.

Open the catalog to page 5

2014 Automotive Composite Floorboard Sandwich Construction: • Glass Mat/Plastic Foam Core • ADVALITE™ – Liquid Vinyl Hybrid Resin • Process: Liquid molding with heated steel tool

Open the catalog to page 6

Composite Floorboards

Open the catalog to page 7

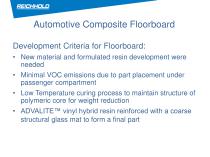

Automotive Composite Floorboard Development Criteria for Floorboard: • New material and formulated resin development were needed • Minimal VOC emissions due to part placement under passenger compartment • Low Temperature curing process to maintain structure of polymeric core for weight reduction • ADVALITE™ vinyl hybrid resin reinforced with a coarse structural glass mat to form a final part

Open the catalog to page 8

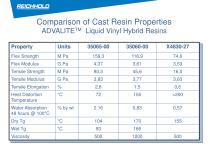

Comparison of Cast Resin Properties ADVALITETM Liquid Vinyl Hybrid Resins Property Flex Strength Flex Modulus Tensile Strength Tensile Modulus Tensile Elongation Heat Distortion Temperature Water Absorption 48 hours @ 100°C

Open the catalog to page 9

GM 2014 Spark Electrical Vehicle Battery Tray • Electric Battery Tray Program – Component – Composite Battery Tray – – Prepreg by Cytec Molded by CSP – Produced using ADVALITE™ Vinyl Hybrid Hot Melt resin • with continuous fiberglass pre-preg • 30° off set barrier, side impact and rear barrier crash testing • Post crash package integrity • 3-meter drop test (bottom /end) • 1-meter water submersion test – Zero VOC Emissions off cured prepreg battery assembly

Open the catalog to page 10

ADVALITE™ Vinyl Hybrid Prepreg Mechanical Properties of Fiberglass Prepreg Units ADVALITETM Composite Tensile Strength Tensile Modulus Short Beam Shear Flexural Strength Flexural Modulus Fiberglass Content

Open the catalog to page 12

Automotive Market Evolution • Global OEM cycle plans call for light weighting vehicles. – BMW i3 Electric Vehicle Example • High fuel prices and CAFE increases necessitate lighter vehicles. • Market and regulation are merging into the same trend. • Current approach is through RTM. – OEMs looking for alternative solution – Current Method is an Epoxy RTM ADVALITETM Vinyl Hybrid Prepregs offer the opportunity for higher productivity rates and excellent mechanical properties. – The question remainsHow does one overcome the need for pre-preg automation?

Open the catalog to page 13

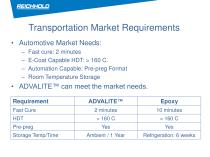

Transportation Market Requirements • Automotive Market Needs: – – – – Fast cure: 2 minutes E-Coat Capable HDT: > 160 C. Automation Capable: Pre-preg Format Room Temperature Storage • ADVALITE™ can meet the market needs. Requirement Fast Cure HDT Pre-preg Storage Temp/Time

Open the catalog to page 14

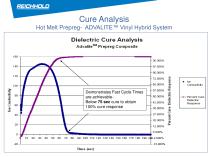

ADVALITE™ Vinyl Hybrid System Dielectric Cure Analysis Advalite™ Prepreg Composite Percent Cure-

Open the catalog to page 15

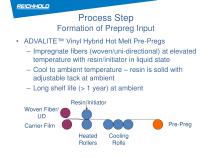

Process Step Formation of Prepreg Input • ADVALITE™ Vinyl Hybrid Hot Melt Pre-Pregs – Impregnate fibers (woven/uni-directional) at elevated temperature with resin/initiator in liquid state – Cool to ambient temperature – resin is solid with adjustable tack at ambient – Long shelf life (> 1 year) at ambient Resin/Initiator Woven Fiber/ UD Carrier Film Heated Rollers Cooling Rolls

Open the catalog to page 16

Automation Solutions: Tape/Pre-preg Lay-up Small Flat Tape Layer - added productivity and increased through-put – Hood inner reinforcement charge in an estimated 3 minutes – Net or Near Net Shape Cutting – Equipment Designed by Fives: JEC Booth S43 – Hall 7/2

Open the catalog to page 17

Automation: Form and Cure Solution Continuous Fiber Form and Cure Prototype Line: Maximum Charge Dimension: 1.5 m x 2.1 m Equipment Supplier: FIVES - JEC Booth S43 – Hall 7/2 Forming Process Material Tension Cassette Hood Inner Indexing Conveyor

Open the catalog to page 18

Continuous Fiber Inner

Open the catalog to page 19

Pre-Preg Value Added Automotive OEM Weight Savings: • High Strength Steel: 7 – 10% • Aluminum: 30 – 50% • Cast Magnesium: 50 – 60% • SMC: 10 – 25% • Carbon Fiber (Epoxy RTM): 40 – 70% • ADVALITE™/FG Pre-Preg: 45 – 55%

Open the catalog to page 20

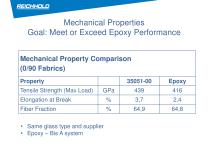

Mechanical Properties Goal: Meet or Exceed Epoxy Performance Mechanical Property Comparison (0/90 Fabrics) Property Fiber Fraction Tensile Strength (Max Load) • Same glass type and supplier • Epoxy – Bis A system

Open the catalog to page 21

ADVALITE™ Vinyl Hybrid Hot Melt Resins Clear Cast Properties Property Flexural Strength Flexural Modulus Tensile Strength Tensile Modulus Water Absorption

Open the catalog to page 22

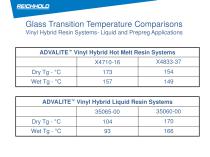

Glass Transition Temperature Comparisons Vinyl Hybrid Resin Systems- Liquid and Prepreg Applications ADVALITE™ Vinyl Hybrid Hot Melt Resin Systems ADVALITE™ Vinyl Hybrid Liquid Resin Systems 35065-00

Open the catalog to page 23

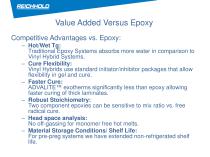

Value Added Versus Epoxy Competitive Advantages vs. Epoxy: – Hot/Wet Tg: Traditional Epoxy Systems absorbs more water in comparison to Vinyl Hybrid Systems. – Cure Flexibility: Vinyl Hybrids use standard initiator/inhibitor packages that allow flexibility in gel and cure. – Faster Cure: ADVALITE™ exotherms significantly less than epoxy allowing faster curing of thick laminates. – Robust Stoichiometry: Two component epoxies can be sensitive to mix ratio vs. free radical cure. – Head space analysis: No off-gassing for monomer free hot melts. – Material Storage Conditions/ Shelf Life: For...

Open the catalog to page 24All Reichhold catalogs and technical brochures

-

UROTUF® F275-M-75

2 Pages

-

EPOTUF® 38-698

2 Pages

-

F600-W-40

2 Pages

-

UROTUF®

7 Pages

-

DION® IMPACT 9133

2 Pages

-

UROTUF® Water-borne Urethane

4 Pages

-

BioiPreferred® Guideline

2 Pages

-

NORPOL® ULTIMATE GELCOAT

2 Pages

-

NORPOL® SVX Gelcoat

2 Pages

-

NORPOL® SVG Gelcoats

3 Pages

-

NEW NORPOL® SRG GELCOAT

2 Pages

-

DION® Corrosion Guide

45 Pages

-

POLYLITE ® 3354225

3 Pages

-

EPOTUF® 38-698

2 Pages

-

Improved vinyl ester technology

21 Pages

-

UROTUF® F600-W-40

2 Pages

-

UROTUF® E300-W-40

2 Pages

-

Corrosion Guide

45 Pages

-

Coating Resins Catalog

35 Pages

-

BECKOSOL AQ®

12 Pages

-

AROFLINT® Flyer

2 Pages

-

Material Selection Guide

77 Pages

-

FRP Inspection Guide

36 Pages

-

Vacuum Foil Infusion

19 Pages

-

RTM Light

15 Pages

-

Pultrusion (Europe)

3 Pages

-

A Reichhold Company Overview

11 Pages

-

NORPOL® VBC Barriercoat

3 Pages

-

NORPOL® GI

3 Pages

-

NORPOL® CPG

4 Pages

-

Pultrusion (EMEA)

3 Pages

-

NORPOL® SVG Gelcoats

4 Pages

-

Fire Retardant (EMEA)

15 Pages

-

Bonding Paste (EMEA)

15 Pages

Archived catalogs

-

Vacuum Foil/ RTM Process (EMEA)

11 Pages

-

Tooling System (EMEA)

11 Pages

-

SMC/ BMC (EMEA)

3 Pages