New Applications for ADVALITE™Vinyl Hybrid Snap Cure Resins in Filament Winding, RTM and Prepreg Processes

34Pages

Catalog excerpts

New Applications for ADVALITE™Vinyl Hybrid Snap Cure Resins in Filament Winding, RTM and Prepreg Processes Jim Bono JEC Paris, March 10th, 2015

Open the catalog to page 1

Background • Advanced Material Market • Styrenated Systems are Unacceptable – Governmental Regulations – Control Technologies Needed – Minimize Capital Investment • Development Need for Reactive Diluent Free Thermoset Resin Systems – Cost Effective – Improved Dry/ Wet Tg – Improved Production Rates- approach 3 minute cycle

Open the catalog to page 2

Nomenclature Styrene Free Resins Alternative Reactive Diluents Reactive Diluent Free Solids: “Prepreg Monomer Free Hot Melt Vinyl Hybrids” ADVALITE™ – Monomer Free Hot Melts Applications: Fiber Reinforced Prepregs Unidirectional Fiber Reinforced Tapes Unidirectional Fiber Reinforced Tow Preg’s Liquids: Reactive Oligomers “Vinyl Hybrid Liquid Resins” ADVALITE™ – Vinyl Hybrid Liquid Resins Applications: Filament Winding, Resin Transfer Molding Liquid Molding, Vacuum Infusion, Pultrusion

Open the catalog to page 3

RTM Filament Winding Vacuum Infusion Gelcoats Pultrusion Closed Mold ADVALITE™ Vinyl Hybrid Liquid Resins- Reactive Diluent Free 4

Open the catalog to page 4

Application Overview Process Applications: • Vacuum Infusion • RTM • Closed Mold • Filament Winding • Pultrusion Uses standard catalysts and initiators – processes the same as UPR and Vinyl Ester resins.

Open the catalog to page 5

ADVALITE™ Liquid Vinyl Hybrid Resins Comparison of Cast Resin Properties Property Tensile Strength Tensile Modulus Tensile Elongation Heat Distortion Temperature Water Absorption 48 hours @ 100°C

Open the catalog to page 6

RTM- ADVALITE™ Requirements Process Requirements • Low initial processing viscosity • Not constrained to injection temperature • Thermal Initiated Stability • Glass Mat Wetting Capabilities • Fast Cure Cycles • Exceed prep time for next preform and finish on previous part • Minimal cure required • Low Shrinkage • Good Mechanical Properties

Open the catalog to page 7

- Processing Conditions of ADVALITE™ X4622 Advalite 4622-88 Viscosity vs Temperature 4622-88 + 1 % TMCH, Viscosity vs Temperature,

Open the catalog to page 8

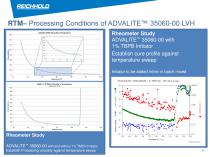

RTM– Processing Conditions of ADVALITE™ 35060-00 LVH Rheometer Study ADVALITE™ 35060-00 with 1% TBPB Initiator Establish cure profile against temperature sweep Initiator to be added Inline or batch mixed Rheometer Study ADVALITE™ 35060-00 with and without 1% TMCH Initiator Establish Processing viscosity against temperature sweep

Open the catalog to page 9

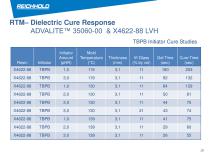

RTM– Dielectric Cure Response ADVALITE™ 35060-00 & X4622-88 LVH TBPB Initiator Cure Studies

Open the catalog to page 10

RTM– Dielectric Cure Response ADVALITE™ 35060-00 & X4622-88 LVH TMCH Initiator Cure Studies

Open the catalog to page 11

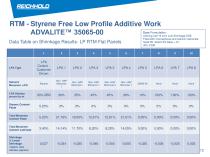

RTM - Styrene Free Low Profile Additive Work Base Formulation: ADVALITE™ 35065-00 Utilizing Cell 10 from Low Shrinkage DOE Filled with microspheres and calcium carbonate Solid PE: Solid LPA Ratio = 5:1 35% CSM Data Table on Shrinkage Results- LP RTM Flat Panels 1 LPA Control Customer Driven Styrene ContentPaste Total Monomer Content Paste Total Monomer Content Laminate Solvent/ Monomer -LPA LPA Dilution percent by wt Shrinkage % Linear Shrinkage -negative value indicates expansion

Open the catalog to page 12

RTM - Styrene Free Low Profile Additive Work ADVALITE™ 35065-00 Base Formulation: Data Table on Mechanical Properties- LP RTM Flat Panels Utilizing Cell 10 from Low Shrinkage DOE Filled with microspheres and calcium carbonate Solid PE: Solid LPA Ratio = 5:1 35% CSM Izod Impact Strength (kJ/ m2)

Open the catalog to page 13

Filament Winding ADVALITE™ Vinyl Hybrid Composite Pipe • Objective: Develop a liquid vinyl hybrid solution to initiate a snap cure through customer’s process while maintaining their fitness for use for the composite. Critical Success Factors: – – – – – – Improvement to Throughput : > 40% Adhesion to PE Tie Layer Water Absorption < 1.5% Tg: > 115 C Elongation: > 3.5% Tack Free Surface Status/Updates: – Tg and Elongation factors controllable through acrylate and rubber modifications to resin formula. Incorporation of toughening additives significantly increased elongation. – Cure and Gel...

Open the catalog to page 14

Filament Winding ADVALITE™ Vinyl Hybrid Toughening ADVALITE™ 35065-00 Toughening 7 6 5 4 Clear Cast Resin Testing • Toughening Additive • Improvement in Fracture Toughness 82 % Increase • Improvement in Elongation 123 % Increase 35065-00 Fracture Toughness (M Pa/m0.5) Elongation (% Tensile Strain)

Open the catalog to page 15

Filament Winding- ADVALITE™ 35060-00 LVH • Develop filament winding resin and Prepreg Wrapped Pipe Oven Cured Samples Cure was completed in less than 80 minutesmostly based on ability of oven to heat up the laminate profile. Once pipe reached appropriate temperature, cure was accomplished in less than 8 minutes. Same cross section of epoxy wound pipe took 36 hrs to cure to manage the exotherm with gradual changes in heat profiles of the oven.

Open the catalog to page 16

Filament Winding- ADVALITE™ Development Composite Tanks • Promoted Resin Initiator TBPB - Inhibitors Different Inhibitors evaluated- selection based on cure response and catalyzed stability

Open the catalog to page 17

Prepreg (Woven and Unidirectional) Mats, Tow Pregs and Tape ADVALITE™ Vinyl Hybrid Solid Hot Melt Resins 18

Open the catalog to page 18

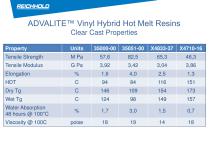

ADVALITE™ Vinyl Hybrid Hot Melt Resins Clear Cast Properties Property Tensile Strength Tensile Modulus Water Absorption 48 hours @ 100°C

Open the catalog to page 19

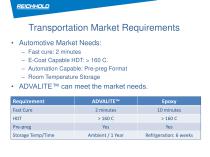

Transportation Market Requirements • Automotive Market Needs: – – – – Fast cure: 2 minutes E-Coat Capable HDT: > 160 C. Automation Capable: Pre-preg Format Room Temperature Storage • ADVALITE™ can meet the market needs. Requirement Fast Cure HDT Pre-preg Storage Temp/Time

Open the catalog to page 20

Structural Plastics

Open the catalog to page 21

Viscosity versus Temperature Profile Monomer Free Hot Melt Vinyl Hybrid Resin- MF-HM-VHR Viscosity Profile Advalite 35051-00 versus Temperature Cone Plate Viscometer CAP 200 Viscosity- centipoise Viscosity Profile Advalite 35051-00 versus Temperature Power (Viscosity Profile Advalite 35051-00 versus Temperature)

Open the catalog to page 22All Reichhold catalogs and technical brochures

-

UROTUF® F275-M-75

2 Pages

-

EPOTUF® 38-698

2 Pages

-

F600-W-40

2 Pages

-

UROTUF®

7 Pages

-

DION® IMPACT 9133

2 Pages

-

UROTUF® Water-borne Urethane

4 Pages

-

BioiPreferred® Guideline

2 Pages

-

NORPOL® ULTIMATE GELCOAT

2 Pages

-

NORPOL® SVX Gelcoat

2 Pages

-

NORPOL® SVG Gelcoats

3 Pages

-

NEW NORPOL® SRG GELCOAT

2 Pages

-

DION® Corrosion Guide

45 Pages

-

POLYLITE ® 3354225

3 Pages

-

EPOTUF® 38-698

2 Pages

-

Improved vinyl ester technology

21 Pages

-

UROTUF® F600-W-40

2 Pages

-

UROTUF® E300-W-40

2 Pages

-

Corrosion Guide

45 Pages

-

Coating Resins Catalog

35 Pages

-

BECKOSOL AQ®

12 Pages

-

AROFLINT® Flyer

2 Pages

-

Material Selection Guide

77 Pages

-

FRP Inspection Guide

36 Pages

-

Vacuum Foil Infusion

19 Pages

-

RTM Light

15 Pages

-

Pultrusion (Europe)

3 Pages

-

A Reichhold Company Overview

11 Pages

-

NORPOL® VBC Barriercoat

3 Pages

-

NORPOL® GI

3 Pages

-

NORPOL® CPG

4 Pages

-

Pultrusion (EMEA)

3 Pages

-

NORPOL® SVG Gelcoats

4 Pages

-

Fire Retardant (EMEA)

15 Pages

-

Bonding Paste (EMEA)

15 Pages

Archived catalogs

-

Vacuum Foil/ RTM Process (EMEA)

11 Pages

-

Tooling System (EMEA)

11 Pages

-

SMC/ BMC (EMEA)

3 Pages