Catalog excerpts

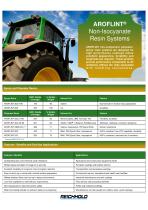

AROFLINT® Non-Isocyanate Resin Systems AROFLINT two-component polyesterepoxy resin systems are designed for high p erfo rmance coatings where excellent appearance, durability and toughness are required. These systems provide performance comparable to 2K urethanes without the risks associated with handling isocyanates. Epoxy and Polyester Resins % Solids, Weight Epoxy Resin Economical for medium-duty applications % Solids, Weight Mineral Spirits, IBIB, Aromatic 100 Flexibility, durability nBuAc, VM&P, n-Butanol, Ethylbenzene Adhesion, hardness, corrosion resistance Xylene, Isopropanol, PM Glycol Ether Solvent resistance MAK, PM Glycol Ether, Isopropanol HAP’s compliant, low VOC capability, durability MAK, PM Glycol Ether, Isopropanol HAP’s compliant, improved dry & hardness Polyester Resin Features / Benefits and End-Use Applications Features / Benefits Outstanding stain and chemical (acid) resistance Agricultural and construction equipment (ACE) Brilliant gloss and depth of image for a wet look Porcelain coatings and bathtub refinish Excellent durability for long-term color and gloss retention Transportation and aerospace coatings Easy to touch-up or recoat with minimal surface preparation Commercial, service, recreational and health care facilities Mildew resistant films that hold up in damp environments Industrial maintenance and tank coatings Low VOC capability to meet 250 g/L requirements Food service and processing facilities Non-isocyanate for improved worker safety Public and industrial buildings Wide formulating latitude for optimum balance of properties Miscellaneous (oil well equipment, battery racks, wood coatings)

Open the catalog to page 1

Performance of AROFLINT® 608 Epoxy with AROFLINT® 809 & AROFLINT® 810 Polyester White Enamel Formula: Air Dry at 77° F / 50% Relative Humidity Stoichiometric Epoxy : Acid Ratio Gardner Circular Dry Time, Set / Thru / Hard Zapon Tack Free, 0g & 200g, Hours König Hardness, 1 / 3 / 7 Days MEK Double Rubs, 1 / 3 / 7 Days Gardner Circular Dry Time: Air Dry at 77° F / 50% Relative Humidity Accelerated Durability: QUV-A340 Exposure Gardner Circular Dry Time ASTM D5895 QUV-A340 60° Gloss & Delta E ASTM G154 Exposure Hours Wide Formulating Latitude: Effect of Changing Component Ratios for...

Open the catalog to page 2All Reichhold catalogs and technical brochures

-

UROTUF® F275-M-75

2 Pages

-

EPOTUF® 38-698

2 Pages

-

F600-W-40

2 Pages

-

UROTUF®

7 Pages

-

DION® IMPACT 9133

2 Pages

-

UROTUF® Water-borne Urethane

4 Pages

-

BioiPreferred® Guideline

2 Pages

-

NORPOL® ULTIMATE GELCOAT

2 Pages

-

NORPOL® SVX Gelcoat

2 Pages

-

NORPOL® SVG Gelcoats

3 Pages

-

NEW NORPOL® SRG GELCOAT

2 Pages

-

DION® Corrosion Guide

45 Pages

-

POLYLITE ® 3354225

3 Pages

-

EPOTUF® 38-698

2 Pages

-

Improved vinyl ester technology

21 Pages

-

UROTUF® F600-W-40

2 Pages

-

UROTUF® E300-W-40

2 Pages

-

Corrosion Guide

45 Pages

-

Coating Resins Catalog

35 Pages

-

BECKOSOL AQ®

12 Pages

-

Material Selection Guide

77 Pages

-

FRP Inspection Guide

36 Pages

-

Vacuum Foil Infusion

19 Pages

-

RTM Light

15 Pages

-

Pultrusion (Europe)

3 Pages

-

A Reichhold Company Overview

11 Pages

-

NORPOL® VBC Barriercoat

3 Pages

-

NORPOL® GI

3 Pages

-

NORPOL® CPG

4 Pages

-

Pultrusion (EMEA)

3 Pages

-

NORPOL® SVG Gelcoats

4 Pages

-

Fire Retardant (EMEA)

15 Pages

-

Bonding Paste (EMEA)

15 Pages

Archived catalogs

-

Vacuum Foil/ RTM Process (EMEA)

11 Pages

-

Tooling System (EMEA)

11 Pages

-

SMC/ BMC (EMEA)

3 Pages