Website:

REHM

Website:

REHM

Catalog excerpts

MEGA.ARC P 300-450 WS CONTINUOUSLY ADJUSTABLE - FOR PERFECT MIG / MAG WELDING RESULTS similar picture

Open the catalog to page 1

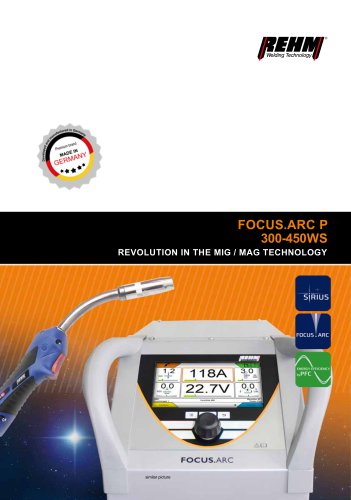

The benchmark for modern MIG / MAG welding Just better welding Whether increasing performance or quality improvement – with the fully digital controlled welding processes FOCUS.ARC you ensure all advantages. Faster • More meters of welding seam per hour • Less rework Better • Better arc control • Less faults • Higher quality Healthier • Eliminated pollution from welding sprays • 80 % less grinding dust FOCUS.ARC is not just a promise, it proves its performance capability. Because only the result counts – please turn over!

Open the catalog to page 2

PURE DIGITAL | Cutting-edge technology perfectly digitized The benchmark in operating welding machines SIRIUS is an innovative digital machine interface. With SIRIUS you get a futureproof intuitive operating system with full I 4.0 connection, which is open for all systems. SIRIUS makes complexity easy. Ingenious • Simplifies the control of complex digital welding processes • Graphically dynamic and transparent visualization • Highest application expertise Flexible • Ready for I 4.0 • Easy integration in manufacturing systems and networks • Free configurable interfaces SIRIUS offers you...

Open the catalog to page 3

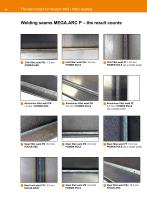

The benchmark for modern MIG / MAG welding Welding seams MEGA.ARC P – the result counts CrNi fillet weld PB I 1.0 mm POWER.ARC CrNi fillet weld PB I 2.0 mm POWER.PULS CrNi fillet weld PF I 5.0 mm POWER.PULS (as a double pulse) Aluminium fillet weld PB 1.5 mm I POWER.ARC Aluminium fillet weld PB 5.0 mm I POWER.PULS Aluminium fillet weld PF 3.0 mm I POWER.PULS Steel fillet weld PB I 8.0 mm FOCUS.ARC Steel fillet weld PB I 5.0 mm POWER.PULS Steel fillet weld PF I 5.0 mm POWER.PULS (as a double pulse) Steel butt weld PG I 2.0 mm FOCUS.ROOT Steel fillet weld PB I 2.0 mm POWER.PULS Steel fillet...

Open the catalog to page 4

MEGA.ARC P For every MIG / MAG application Digitally controlled welding processes for all applications POWER.PULS Very good modulation of the welding process for steel, stainless steel and aluminium • Faster welding of stainless steel with weld seam surface almost similar to TIG • Very little temper colour, electrochemically eliminable • Adjustable heat input • Welding seams in TIG optic, by using double pulse • Overweldable spots • The arc-length adjustment either via voltage or wire POWER.ARC Standard welding process • Quiet, stable arc • High arc stability • High energy arc FOCUS.ROOT...

Open the catalog to page 5

The benchmark for modern MIG / MAG welding SIRIUS opens up new potentials SIRIUS simplifies the operation of complex welding processes by visualization and assist functions. Modern digitally controlled machines offer multiplicity ways of improvement, which need to be utilized in the industrial production. Increase your competitiveness, by making unused potential transparent with SIRIUS. • SIRIUS ensures the easy and fast access on unutilized potentials • SIRIUS supports the performance and quality with it´s clear structures and simplifies the work of the welder • SIRIUS is multilingual •...

Open the catalog to page 6

SIRIUS | The highest standard for digital control, connectivity and communication SIRIUS* with Open Connect is fully Industry 4.0 capable The possibilities to communicate digitally through SIRIUS are endless. The interface architecture of SIRIUS can be configured and expanded in any way. Easy embedding into existing systems via integrated server module. SIRIUS communicates via all established interfaces like Ethernet, USB, CAN-bus, LAN, W-LAN, 2,4 GHz Wireless technology. • • • • • SIRIUS is not an single application, only for the documentation of welding data SIRIUS offers full embedding...

Open the catalog to page 7

The benchmark for modern MIG / MAG welding Power station • Ultrafast inverter poor of inductivity • Own processor control for quick reaction in the arc • Contains PFC (Power Factor Controller) • Wide range input voltage • 450 amperes out of 9 kg weight • Intelligence beats weight Undercarriage Advanced Big wheels • Front 160 mm with fixing brake • Rear 260 mm Gas bottle mount • Robust mount for up to 50 l Wheel arches in the back • Prevents the pover cords to be squeezed while moov

Open the catalog to page 8

MEGA.ARC P | Highly innovative technology, continuously adjustable Everything under control • Ergonomic designed handle bars for save stearing Wire feeder • Digital controlled precise and powerfully 4-wheel drive • Feeder rolls are according to the wire diameter coded by colours • Quick change system for feeder rolls without tools • Contact pressure for inlet and outlet independently adjustable Intelligent water cooling unit • Circular pump for high output flow • Energy management only cools on demand based on temperature sensing of coolant • Conserves resources • Increases live time of all...

Open the catalog to page 9

The benchmark for modern MIG / MAG welding THAT SPEAKS FOR THE REHM COBOT SYSTEM: ■ Short payback period ■ Reduction of manufacturing costs ■ Higher productivity (24/7) ■ Prevents a shortage of skilled workers and relieves the qualified employees ■ Problem-free integration into operational processes ■ System is configured according to customer requirements ■ Compact design saves expensive production space ■ Offers attractive new task ■ Easy to use ■ Consistent welding quality all times You will find more information about our COBOT System here:

Open the catalog to page 10

MEGA.ARC P | The perfect solution for all requirements Features MEGA.ARC P There is the right variant for every requirement, with the always suitable equipment. EQUIPMENT SIRIUS operating and communication system Job memory Welding process FOCUS.ARC Welding process POWER.ARC Welding process FOCUS.ROOT Welding process POWER.PULS MIG / MAG procedure MMA procedure Gouging procedure CONTROL PANEL MEGA.ARC P 300-450 WS Menu button Home button Return button Selection buttons R-Pilot encoder Impact protected full colour display Assist function

Open the catalog to page 11All REHM catalogs and technical brochures

-

COMPLETE PROGRAMME 2024

64 Pages

-

INVERTIG i 260 DC-450 AC/DC HIGH

12 Pages