Website:

REHM

Website:

REHM

Catalog excerpts

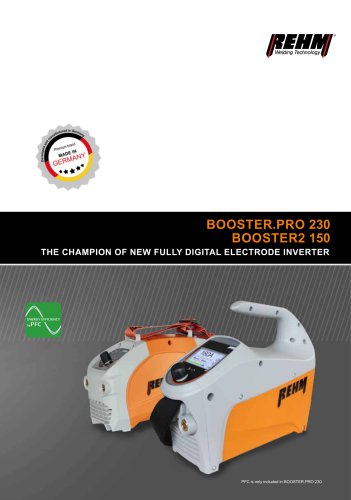

THE CHAMPION OF NEW FULLY DIGITAL ELECTRODE INVERTER PFC is only included in BOOSTER.PRO 230

Open the catalog to page 1

The benchmark for electrode welding machines THE BENCHMARK IN OPERATING WELDING MACHINES SIRIUS is an innovative digital operating system. SIRIUS simplifies the operation of complex digitally controlled processes. SIRIUS offers graphically dynamic and transparent visualization. SIRIUS enjoys the highest level of user acceptance. SIRIUS makes complex things simple. THE NEW BOOSTER.PRO 230 The electrode welding machine for professionals - with new extended range of functions in the proven TIGER design. FULLY DIGITAL TECHNOLOGY 160A All important information at a glance Thanks to SIRIUS, the...

Open the catalog to page 2

BOOSTER.PRO 230 | The professional, for professionals Electrode pulse welding Hot start freely adjustable Improves the welding properties in difficult positions, creates a higher gap bridging ability and is suitable for both visible seams and vertical seam welds. Facilitates safe ignition through short-term current increase. SoftStart Integrated Anti-Stick Stable arc at the start, for electrodes with low welding current. Prevents sticking and annealing electrode on the workpiece and thus also avoids weld defects. LiftArc ignition ArcForce freely adjustable Stabilizes the arc - even with...

Open the catalog to page 3

The benchmark for electrode welding machinesADJUSTMENT PARAMETERS FUNCTIONALITY ■ Welding current 1 ■ Welding current 2 ■ Hot start ■ ArcForce ■ Anti-stick ■ Pulse times I1 and I2 ■ HYPER.PULS frequency up to 17,500 Hz ■ Synergy characteristics for basic and rutile electrodes ■ Safety hold function ■ BOOSTER function ■ Time pulses ■ REHM HYPER.PULS ■ VRD function (reduced open circuit voltage) ■ TIG function with contact ignition POWER FACTOR CONTROLLER (PFC) Energy saving The Power Factor Controller regulates the current consumption and adjusts it to the voltage curve. This ensures that...

Open the catalog to page 4

Fully digital technology, full range of functions Setting range TIG Electrode (BOOSTER) Electrode (fuse hold) Duty cycle (ED) at Imax. TIG Electrode (BOOSTER) Electrode (fuse hold) Welding current at 100% ED TIG Electrode (BOOSTER) Electrode (fuse hold) incl. case, earth and electrode cable 25 mm2, wire brush, chipping hammer ■ ACCESSORIES TIG torch with separate gas regulation Torch TIG R TIG 141 4m VS26 + gas 3m 7636186 Earth cable Earth cable 25mm2 4m 13 400A clamp 7810101 Electrode cable Electrode cable 25mm2 5m 13 260A clamp 7810201 Mounting case Mounting case T3 2600423

Open the catalog to page 5

The benchmark for electrode welding machines Ultra-modern technology. Uniquely implemented. A fault due to a fall or impact? In the event of a fall, the REHM Pre-Save System protects the electronics inside the device better than conventionally designed welding devices. Power to weight ratio 65A/kg! The world champion in its class, with 150 A welding current and weighing only 2.3 kg. Contamination of the electronics? The proven REHM cooling system that reliably keeps the cooling system and electronics separate from each Setting range Duty cycle (ED) at Imax. Welding current at 100% DC...

Open the catalog to page 6

BOOSTER2 150 | Excellence technology cuts weight in half BOOSTER2 when used in steel construction. Ultramobile, safe handling and full performance. ULTRA MODERN AND FULLY DIGITAL. PERFECT AND RELIABLE. ■ Fully digital technology ■ Ultra-fast, low-induction Inverter ■ Energy cost saving IMS inverter technology ■ Unique, functional appearance ■ Fully insulated, protection class 2 ■ Suitable for generators ■ Works with 100 m mains cable ■ Fuse hold function ■ Front and back as well as device base made of impact-resistant plastic ■ Splash water protected according to IP 23 ■ Above average...

Open the catalog to page 7

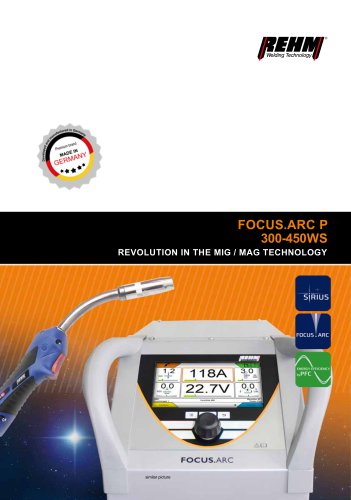

■ REHM MIG / MAG welding machines ■ REHM TIG welding machines ■ REHM MMA electrode inverter ■ REHM PLASMA cutting systems ■ Welding accessories and consumables ■ Welding fume extraction ■ Technical welding advice ■ Torch repairs ■ Service WEEE-Reg.-Nr. DE 42214869 REHM GmbH u. Co. KG SchweilJtechnik Tel.:+49 (0) 7161 3007-0 E-Mail: rehm@rehm-online.de Ottostralie 2 I 73066 Uhingen I Germany Fax: +49 (0) 7161 3007-20 Internet: www.rehm-online.de

Open the catalog to page 8All REHM catalogs and technical brochures

-

COMPLETE PROGRAMME 2024

64 Pages

-

INVERTIG i 260 DC-450 AC/DC HIGH

12 Pages