Website:

REGO-FIX

Website:

REGO-FIX

Catalog excerpts

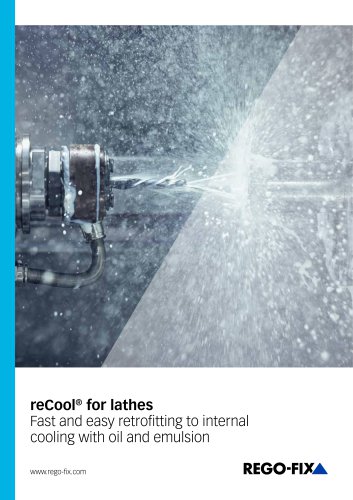

reCool® for lathes Fast and easy retrofitting to internal cooling with oil and emulsion www.rego-fix.com REGO-FIXA

Open the catalog to page 1

External flood cooling Peripheral cooling Internal cooling Supplying the right amount of coolant to where it matters Key features of external flood cooling Key features of peripheral cooling Universal application possibilities Problems may arise with deep cavities Reduction of tool life because cooling is not right on the cutting edge Suboptimal chip deflection Limited adjustment of nozzles due to different tool lengths and diameters Achieve peripheral cooling with reCool® and the use of our coolant flush disk KS / ER // Coolant is fed along the side of the tool to the cutting edge // Can...

Open the catalog to page 2

Internal cooling solution: reCool® RCS / RCR Low-cost retrofitting to internal cooling Retrofit flood cooling to internal cooling in two minutes with reCool®. Available for both static tooling systems and driven tools. Key features of reCool® static RCS for use with static holders // Cost-friendly conversion of existing static tooling systems to through coolant in only two minutes For ER collets (DIN 6499 / ISO 15488) in stationary colletholders with external threads* Coolant pressures of up to 150 bar** RCS / ERMX for emulsion and oil coolants Low-maintenance design For coolant through...

Open the catalog to page 3

Automotive industry reCool® gets you more for less Achieve operational excellence by reducing manufacturing time and securing production chains. Customer 1 Production of metal tubes for air-conditioning sensors Working time / piece (sec) Tool life ' (parts x 1,000) Parts per day up by 325 % Time per piece down by 77 % Operations per part down by 75 % Logarithmic scale conventional with reCool® Automotive industry Automotive manufacturers and suppliers are confronted with increasing process complexity, shorter technology cycles and steady pressure to innovate. Benefits of reCool® reCool®...

Open the catalog to page 5

Turning application Bring coolant to where it matters Reduce coolant quantity by retrofitting from flood cooling to internal or peripheral cooling. Customer 2 Production of hydraulic cylinders Coolant pressure (bar) 64 32 Working time / piece (min) Tool life (parts x 1,000) Working time down by 50 % Spindle speed up by 100 % // Operations per part down by 75 % // Logarithmic scale conventional with reCool® by 55 bar. This leads to perfect cooling of the cutting edges and improved chip removal too. Alan Fastner Product manager for reCool® What is the biggest benefit for customers when...

Open the catalog to page 6

Customer 3 Production of contacting blocks for the power-electronics industry Working time / piece (min) Tool life (parts) Pressure up by 700 % Parts per day up by 300 % // Tool life up by 275 % // Logarithmic scale conventional with reCool® Reduction of machine downtime is a major goal in production simply because downtime means loss of profit. Internal cooling with reCool® increases your tool life. Thus, effectively reducing not only tool costs but also downtime. REGO-FIX supports manufacturers with insightful produc

Open the catalog to page 7

User report Perfectly prepared for everything Contract manufacturer, machine builder, and system constructor Sumec AG, headquartered in Niederbipp, Switzerland, recently retrofitted its machining centers with REGO-FIX’s reCool® coolant-through lubrication system. To be able to have competitive and profitable production operations in an expensive location such as Switzerland, manufacturing experts keep investing in modern technology as can be seen in the features being added to CNC machining centers. The goal was making a difficult part on a CNC machining center in a single pass to have...

Open the catalog to page 9

Discover the reCool® universe Maximum cooling possibilities reCool® is made for static and rotary applications and offers cooling possibilities for peripheral and internal cooling, while making best use of your existing toolholding equipment. Recommended torque wrench TORCO-FIX for reCool® RCS and reCool® RCR Matching wrenches and wrench heads reCool® RCS for static applications reCool® RCR for rotary applications Peripheral cooling Coolant flush disk KS / ER Internal cooling Sealing disk DS / ER Standard ER or ER-UP collet Standard ER and ER mini cylindrical toolholders or dri

Open the catalog to page 11

reCool® static RCS for use with static tools Type Part no. B D Thread Wrench RCS / ERMX nut (for emulsion- and oil-based coolants) Accessories are notindudedin delivery

Open the catalog to page 12

reCool® rotary RCR for driven tools Set RCR-E&O / ER (for emulsion- and oil-based coolants) Included in set RCR/ER Type Qty. Type Part no. B D Thread Wrench RCR-E&O / ER nut (for emulsion- and oil-based coolants) Accessory Included in set RCR/ERM Thread Wrench Type Qty. Set RCR / ERM (for emulsion- and oil-based coolants) M 30 X 1 E 25 AX See page 12 for contents. RCR / ERM nut (for emulsion- and oil-based coolants) Accessories are not included in delivery

Open the catalog to page 13

Type Part no. [mm]

Open the catalog to page 14

Type Part no. [mm] [inch] Type Part no. [mm] Incl. in set Type Part no. [mm] Incl. in set included in the DS/ER sets are ail marked disks within that ER size and the matching disk tray DSR. 15

Open the catalog to page 15

Sealing disks DS / ER Compatible with reCool® RCS and RCR for internal cooling

Open the catalog to page 16

Sealing disks DS / ER Compatible with reCool® RCS and RCR for internal cooling

Open the catalog to page 17

reCool® accessories High-pressure hoses (≤150 bar) with threaded 1/8" ends Fitting sets (2 pieces each) Aluminum ring adapters RRA (1/8" BSP) Expert advice The ball adapter RBA is used when the driven tool has a ball connection. The fitting can then be used on the hose. High-pressure hose SET RHS-HP The aluminum ring adapter RRA can be used when the driven tool cooling connection uses the “press-in” principle.

Open the catalog to page 18

internal thread Colletholders and driven tools with internal thread are specially designed for smaller lathes and Swiss automatics that have limited space and many mounted tools. Thanks to their shortness they possess a superior stiffness and do not protrude heavily from the tooling revolver. This shortest possible projection increases the axis of travel of the machine and allows larger workpieces to be machined. reCool® adapter The reCool® adapter RC-ADP easily converts inner-threaded driven tools to outer-threaded version. This enables the use of the reCool® rotary coolant supply...

Open the catalog to page 19All REGO-FIX catalogs and technical brochures

-

ER System

166 Pages

-

powRgrip System

90 Pages

-

micRun System

58 Pages

-

Product novelties 2018

2 Pages

-

TORCO-BLOCK

4 Pages