Website:

REGO-FIX

Website:

REGO-FIX

Catalog excerpts

powRgrip® System The ambitious toolholding system Product catalog

Open the catalog to page 1

Company profile Providing solutions for cutting-edge toolholding Product offering 04 Automatic clamping unit PGU 07 Customer testimonial: powRgrip® in use 08 Special solutions: XL colletholders 10 Special solutions: PG secuRgrip® and Heavy Duty 12 1.0 PG colletholders Minimize runout - boost productivity 17 Standard spindle interfaces 1.1.1 SK interface 1.1.4 REGO-FIX CAPTO interface licensed by Sandvik Coromant 1.1.5 Cylindrical (CYL) interface 1.2 PG secuRgrip® colletholders SK, BT, BT+, HSK-A, C 1.3 PG tapping holders HSK-A SSY, CYL SSY, CYL GSF 2.0 PG collets The...

Open the catalog to page 2

Experience the powerful powRgrip® range REGO-FIX CAPTO/PG Pullout protection secuRgrip® licensed by Sandvik Coromant Cylindrical colletholders Long shanks Short shanks Turning collets Pullout protection secuRgrip® Micro machining Suitable for carbide or HSS milling cutter in all shank forms (Weldon, Whistle-Notch, etc.) For the automatic clamping unit PGU 9500 and other accessories please refer to page 72.

Open the catalog to page 3

At a glance Providing solutions for cutting-edge toolholding Our holistic toolholding systems excel with extraordinary reliability, high precision and outstanding quality. Pioneering spirit Fritz Weber, a Swiss master craftsman, tapped into the promising optimism in the 1950s and founded a small business called Fritz Weber Feinmechanik und Werkzeugbau. With his innovative spirit and stern determination, Fritz Weber gradually expanded his range of products. The company, now called REGO-FIX AG, achieved international recognition in 1972 with the invention of the ER clamping system. Thus,...

Open the catalog to page 4

powRgrip® System Meet high machining demands The powRgrip® System provides excellent runout, high vibration dampening as well as easy and secure handling for demanding high-speed milling and drilling. The clamping unit PGU 9500 has been awarded a Red Dot award for industrial design, highlighting the good usability and outstanding design of the machine. Excellent vibration dampening. Power and precision combined An outstanding tool runout is one of the most positive influences on enhancing your tool life. Increased cutter tool life with the powRgrip® System Influence of tool runout on tool...

Open the catalog to page 5

Product offering Three systems – one brand Our brand unites three different toolholding systems. Each system has different strengths to fit your machining needs, but at the heart of each system lies our aim for toolholding excellence. powRgrip® System For high-end machining with a total system TIR ≤3 μm at 3 x D PG colletholders Clamping range from 0.2 up to 25.4 mm Special surface treatment ensures longevity High transferable torque up to 1,100 Nm Clamps all shanks with tolerance h6 Vibration dampening for high RPM A holistic system approach All parts are designed for exclusive fit to...

Open the catalog to page 6

micRun® System Total system TIR ≤3 μm at 3 x D MR colletholders Clamping range from 1.0 mm to 20.0 mm Collet-locking system Polished surface for improved performance Nominal diameter shanks h11 Grooveless design for higher RPM Vibration dampening Freewheel wrench head A holistic system approach All parts are designed for exclusive fit to ensure toolholding excellence.

Open the catalog to page 7

Discover powRgrip® Concentricity and optimum vibration dampening saves time and money The innovative technological accomplishment is reflected in the uniqueness of the tool-clamping procedure in a demanding high-precision environment, as well as the persistence of the clamped toolholder. Thanks to the unique clamping method of PGU, the clamped tools can be used in production quickly and safely. The advanced technology not only increases the work safety for the user, but also reflects our ecological thinking, which manifests itself – among other things – through low energy consumption during...

Open the catalog to page 8

Automatic clamping unit PGU Toolholding made fast, safe and easy The clamping unit PGU 9500 has been awarded the Red Dot design award for industrial design, highlighting the good usability and outstanding design of the machine. Clamp the tool safely and securely by pushing just one button. The clamping will take less than 10 seconds, without the use of heat. PG System / Product catalog Clamp tools with maximum clamping force and best runout in the powRgrip® collet and colletholder. Smart System – no setting of parameters required. Clamping pressure is controlled by the insertion of the...

Open the catalog to page 9

powRgrip® won us over from the very beginning – and has continued to do so over the years – with its high holding forces, the possibility of internal cooling, and its speed. powRgrip® covers everything. Holger Kraeft Managing Director of DeickenmicRun® closeup & Engels Customer testimonial: powRgrip® in use Going all in with powRgrip® Contract manufacturer Deicken & Engels Maschinenfabrik GmbH & Co. KG has based its entire production on a single toolholding system: powRgrip®. The company in northern Germany has experienced firsthandedly the flexibility of powRgrip®, its runout accuracy and...

Open the catalog to page 10

a base stock of tools which remain in the machine. With a 100-piece tool magazine, basic equipment with 60 tools remain in the machine and can be used for approximately 80 % of all machining. With this strategy, a greater initial investment had to be made for the basic equipment of the machines. In the long run this way is without a doubt the more sustainable investment. XL length toolholders are standard in the REGO-FIX product range and are immediately available. Their long and slim design allows for precise machining even with limited space. Deicken & Engels has achieved improvements in...

Open the catalog to page 11

Special solutions: XL colletholders XL vibration dampening Optimize your surface finish and extend tool life by minimizing occurring vibrations during machining. Minimize tool vibrations The MICRO-FRICTION DAMPENING™ (MFD) technology (pat. pend.) by REGO-FIX allows our XL colletholders to dissipate vibrations faster than standard long-reach colletholders. Dampening the vibrations faster means that your cutting tool, part and spindle will see less vibrations resulting in better surface finishes, longer tool life and less spindle wear. All REGO-FIX XL colletholders are balanced to G 2.5 @...

Open the catalog to page 12All REGO-FIX catalogs and technical brochures

-

ER System

166 Pages

-

micRun System

58 Pages

-

Product novelties 2018

2 Pages

-

TORCO-BLOCK

4 Pages

-

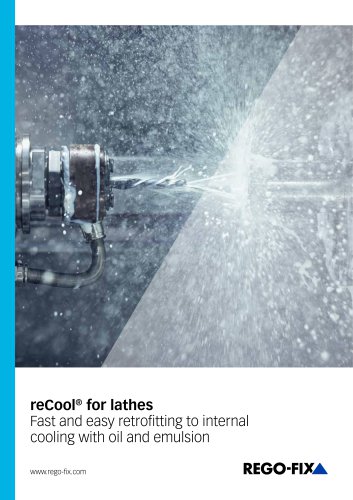

reCool® for lathes

24 Pages