Catalog excerpts

AeroCres Fracture-tough Airframe Products Fracture-tough airframe products enhance corrosion resistance For many years, corrosion has been a signicant problem with bearings used in the aircraft industry. While CRES 440C has been used successfully in many aircraft applications, it is not suitable for the demands of rod end banjos or track roller studs. These two bearing components require a full Rc 58 hardness in the raceway area and a softer, tougher material elsewhere. This is not attainable with CRES 440C. RBC’s AeroCres® products provide the unique solution that meets these dual material requirements. We have selected a specialized carburized stainless steel, and have developed and optimized the heat treatment process that resulted in a homogeneous microstructure — delivering both corrosion protection and core fracture toughness. Currently, this new material is being used for many structural bearing components such as rod end banjos, track roller studs, and outer rings. Fracture toughness, corrosion resistance, and long fatigue life are critical requirements for these components. AeroCres® fracture-tough airframe products offer enhanced corrosion resistance in harsh operating environments. Benets • Excellent fracture toughness superior to CRES 440C. • Proven corrosion resistance similar to CRES 440C. • Compressive residual stresses in carburized case. Applications • Meets or exceeds government requirements for fatigue and static testing per AS 39901. • Longer bearing life resisting premature corrosion. Bearings located in exposed corrosive positions of aircraft such as: • Landing gear and doors • Leading and trailing edges • Engine controls • Lower starting torque after extended exposure to a neutral salt solution (ASTM-G44). • Tail sections

Open the catalog to page 1

AeroCres Fracture-tough Airframe Products Corrosion Resistance Comparison AeroCres® Rod End vs. 8620/52100 Rod End Alternate Immersion Corrosion Test ASTM G44-88 Results* (1,000 hours) Standard Assembly: 8620 rod end outers with 52100 steel inner ring and balls Corrosion Resistant CRES Assembly: AeroCres® rod end outer with CRES 440C inner ring and balls Fig. 6 – Average Torque to Rotate for Three Bearings of Each Type of Rod End Salt Spray Test Results (1,000 hours) ASTM-B117 Alternate Immersion Corrosion Test ASTM G44-88 Results* (1,000 hours) Microstructure AeroCres® fracture-tough...

Open the catalog to page 2All RBC Bearings catalogs and technical brochures

-

G Series

1 Pages

-

DPP, DPP-W series

1 Pages

-

MS 21428/MB500DD

1 Pages

-

DSRP, GDSRP series

1 Pages

-

Spherco

36 Pages

-

Aerospace - Applications

2 Pages

-

Aerospace Catalog - Plain Bearing

115 Pages

-

Aerospace Catalog - Rolling Element

152 Pages

-

MB500 Series

1 Pages

-

MKP-BS Series

1 Pages

-

MS27642-S MKP-B Series

1 Pages

-

MS27641-R MKP-A Series

1 Pages

-

MS27640-R MKP Series

1 Pages

-

P Series

1 Pages

-

K Series

1 Pages

-

MS27646 B500DD Series

1 Pages

-

B500 Series

1 Pages

-

MS27648 KP-BS Series

1 Pages

-

MS27642 KP-B Series

1 Pages

-

MS27645 KSP, KSP-A Series

1 Pages

-

MS27649 AW-AK Series

1 Pages

-

MS27641 KP-A Series

1 Pages

-

MS27640 KP Series

1 Pages

-

Metric Product Line

2 Pages

-

Military Series

4 Pages

-

BHM

1 Pages

-

Lubron® Bearing Systems

6 Pages

-

Fiberglide ® /Fabroid ®

27 Pages

-

Schaublin - Unibal

51 Pages

-

Nice Ball Bearings

56 Pages

-

Thin Section Ball Bearings

153 Pages

-

Heim Rod Ends and Sphericals

33 Pages

-

Cam Followers

56 Pages

-

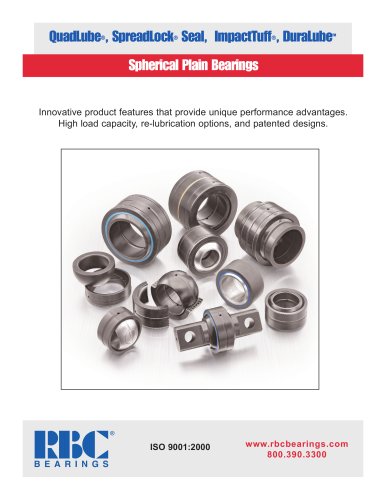

Spherical Plain Bearings

84 Pages

-

RBC Line Card

3 Pages

-

Large Thrust Bearings

4 Pages

-

ImpactTuff

2 Pages

-

CrossLube

2 Pages

-

Nice Everglide T-Ball

2 Pages

-

SpreadLock Seal

2 Pages

-

Large Bearings

2 Pages

-

Aerospace Catalog - Rolling Element

152 Pages

Archived catalogs

-

Fiberglide®/ Fabroid®

28 Pages

-

Tyson Tapered Roller Bearings

16 Pages

-

Thin Section Ball Bearings

44 Pages

-

Spherical Plain Bearings

68 Pages

-

Heim Rod Ends

64 Pages

-

Ball Bearings Brochure

52 Pages

-

RBC Roller® Cam Followers

8 Pages