Catalog excerpts

Series J Shaft Mounted Gearbox

Open the catalog to page 1

PRODUCTS IN THE RANGE Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive, aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions. Series A Worm Gear units and geared motors in single & double reduction types Series BD Screwjack worm gear unit Series BS Worm gear unit Series C Right angle drive helical worm geared motors & reducers Series F Parallel shaft helical geared motors & reducers Series G Helical parallel shaft & bevel helical right angle drive gear units Series H Large...

Open the catalog to page 2

ATEX Compliance Assured Total compliance with the ATEX Directive safeguarding the use of industrial equipment in potentially explosive atmospheres is assured for users of our geared products. Certification is available for standard gearboxes and geared motors with badging displaying the ATEX zone, name and location of the manufacturer, designation of series or type, serial number, year of manufacture, Ex symbol and equipment group/category. ATEX directive 94/9/EC (also known as ATEX 95 or ATEX 100A) enforced in all EC member states. Compliance is compulsory for designers, manufacturers or...

Open the catalog to page 3

SERIES J CONTENTS PAGE General Description __________________________________________________________________ 3 Unit Designations ____________________________________________________________________ 4 Selection Procedure __________________________________________________________________ Power ratings / Thermal power ratings 1-stage _______________________________________________________________________ 7 2-stage 15:1 ___________________________________________________________________ Selection of V-belt drives Power ratings V-belt transmissions...

Open the catalog to page 4

Series J Shaft Mounted Speed Reducers are high quality products, submitted to intense quality control and manufactured with the highest precision. — Worldwide after sales service — 19 types up to 600 kW, 57000 Nm — Wide range of standard accessories — High efficiency — Long gear and bearing lifetime — All mounting positions possible — Easy to mount — Easy to change speed through change of V-belt transmission — Space saving — Low noise level — Easy to service, due to standard components The shaft sleeve is supplied with tapped holes for dismounting the reducer as well as locking the reducer...

Open the catalog to page 5

COOLING OPTIONS (ONLY J100 - 190) NO ADDITIONAL COOLING ELECTRIC FAN OIL COOLER 00' 00 LEFT ROTATION (Counter-Clockwise) 00 RIGHT ROTATION (Clockwise) MOUNTING POSITIONS H2 STANDARD H5 VERTICAL UP H6 VERTICAL DOWN H1 SPECIAL * SEE PAGE 68 * SPECIFY INCLINATION ETC INPUTSHAFT STANDARD MC - IEC FLANGE * HD - HYDRAULIC MOTOR * SPECIAL * SPECIFY MOTOR SIZE *THIS PAGE MAY BE PHOTOCOPIED ALLOWING THE CUSTOMER TO ENTER THEIR ORDER ** AVAILABLE ON REQUEST For online product selection/configuration and 2D/3D models of Series J visit www.benzlers.solidcomponents.com 4

Open the catalog to page 6

SERIES J SELECTION PROCEDURE Definition of service factor The torque ratings apply to service factor fb = 1.0. The service factor fb = 1.0 gives continual operation 4 to 8 hours a day at a uniform load without shocks and with 10 to 200 starts an hour. The moment of inertia of the driven machines is less than 20 % of the electric motor inertia and occasional peak torque may not exceed 1.8 times the torque rating. For other running conditions compensate with service factors according to tables. Mechanical Rating Determine the demand of power (Pe kW) or torque (Te Nm) and speed (ne min -1 ) to...

Open the catalog to page 7

Service factors Table 1. Service factor fb

Open the catalog to page 8

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 Ibf.ft)

Open the catalog to page 10

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 Ibf.ft)

Open the catalog to page 11

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 ibf.ft)

Open the catalog to page 12

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 Ibf.ft)

Open the catalog to page 13

Double reduction The torque is shown in Nm (1 Nm = 0.102 kpm = 0.7376 ibf.ft)

Open the catalog to page 14

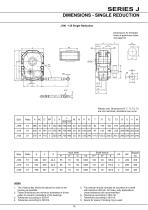

Please note: Dimensions R, T, T1, T2, T3 are not machined, deviations can occur. 1. The V-belt pulley should be placed as close to the housing as possible. 2. These dimensions are minimum diameters of driven pulley to prevent overloading of the bearings. 5. The reducer should normally be mounted on a shaftwith tolerance ISO js6. On heavy duty applications closer tolerances are recommended. 8. Space for spacer if locking ring is used.

Open the catalog to page 15

1. The V-belt pulley should be placed as close to the housing as possible. 2. These dimensions are minimum diameters of driven pulley to prevent overloading of the bearings. 5. The reducer should normally be mounted on a shaft with tolerance ISO js6. On heavy duty applications closer tolerances are recommended. 8. Space for spacer if locking ring is used.

Open the catalog to page 16

Dimensions for threaded holes at gearhouse sides, see page 53. Please note: Dimensions R, T, T1, T2, T3 are not machined, deviations can occur. 1. The V-belt pulley should be placed as close to the housing as possible. 2. These dimensions are minimum diameters of driven pulley to prevent overloading of the bearings. 5. The reducer should normally be mounted on a shaft with tolerance ISO js6. On heavy duty applications closer tolerances are recommended. 8. Space for spacer if locking ring is used.

Open the catalog to page 17

1. The V-belt pulley should be placed as close to the housing as possible. 2. These dimensions are minimum diameters of driven pulley to prevent overloading of the bearings. 5. The reducer should normally be mounted on a shaft with tolerance ISO h8. On heavy duty applications closer tolerances are recommended. 8. Space for spacer if locking ring is used.

Open the catalog to page 18

Please note: Dimensions R, T, T1, T2, T3 are not machined, deviations can occur. notes 1. The V-belt pulley should be placed as close to the housing as possible. 2. These dimensions are minimum diameters of driven pulley to prevent overloading of the bearings. 5. The reducer should normally be mounted on a shaft with tolerance ISO js6. On heavy duty applications closer tolerances are recommended. 8. Space for spacer if locking ring is used.

Open the catalog to page 19All Radicon catalogs and technical brochures

-

Series M Helical In-Line

116 Pages

-

BR-Series-AM.

72 Pages

-

adicon-SeriesX

32 Pages

-

BR Series F

117 Pages

-

Radicon Series X Couplings

32 Pages

-

BR Series X Couplings

36 Pages

-

BR Cone Ring Couplings

16 Pages

-

Motor

4 Pages

-

Series E Flyer

4 Pages

-

G series

4 Pages

-

BD

4 Pages

-

Product Brochure radicon

8 Pages

-

Benzlers Screw Jacks

69 Pages

-

Series J - Shaft Mounted Gearbox

15 Pages

-

Radicon Series ET

42 Pages

-

BR Series G

71 Pages

-

Metric

8 Pages

-

Geared Pump

15 Pages

-

Series P Planetary

4 Pages

-

M series

120 Pages

-

Sala Gears

74 Pages

-

Roloid Pump

17 Pages

-

Heavy Duty Worm Gear Series ER

15 Pages

-

Screw Jacks

58 Pages

-

Series AM Worm Gear

73 Pages

-

Worm Gear Series AJ

89 Pages

-

Series BS Worm Gear

60 Pages

-

Elflex Flexible Couplings

8 Pages

-

Series H industrial gearboxes

123 Pages

-

SERIE G

71 Pages

-

C series

120 Pages

-

Geared Motor Series K

90 Pages

-

F series

119 Pages

-

Elign Gear Couplings

17 Pages

Archived catalogs

-

Worm Gears Series AH

13 Pages