Catalog excerpts

with you at every turn RoLoid Gear Pump

Open the catalog to page 1

Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive, aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions. Worm Gear units reduction types Parallel angle helical bevel helical geared motors & reducers Right angle helical bevel helical geared motors & reducers Screwjack worm gear unit Helical parallel shaft & bevel helical right angle drive gear In-line helical geared motors & reducers Worm gear unit Large helical parallel shaft & bevel helical right angle drive units Roloid Gear...

Open the catalog to page 2

ROLOID GEAR PUMP & SERVICE FACTORS Product And Application Information _ 4 Roloid Pump Selection Guide - Nominal Flow_ 6 Roloid Pump Selection Guide - Power to Drive_ 7 Dimensions Standard Pump Type H - Base Mounted_ 8 Dimensions Standard Pump Type H - Flange Mounted_ 9 Dimensions Motorised Standard Pump_ 10 Dimensions HST Pump Type T - Base Mounted _ 11 Dimensions HST Pump Type T - Flange Mounted _ 12

Open the catalog to page 3

ROLOID GEAR PUMP The Roloid Gear Pump is robust, compact and versatile. It is easy to install, extremely reliable, and requires little maintenance during service. The pump design and product range have matured over many years and in combination with Radicon excellence, represents an economic and reliable solution to lubrication and fluid transportation requirements. Roloid Gear Pumps are suitable for pumping a wide variety of liquids which have some lubricating property. Our application engineers will gladly assist in selecting a pump that will give trouble free operation. Roloid Gear Pumps...

Open the catalog to page 4

ROLOID GEAR PUMP AVAILABLE PUMP VARIATIONS Base Mounted Unit The Base Mounted Roloid Gear Pump is available as standard in 7 sizes (90 to 25) giving output flow rates between 3.9L/min to 1052L/min, A further 2 sizes (20 and 15) are available upon special request for achieving flow rates up to 2546L/min. All pumps come as standard with Ansi B16.5 Class 150 connection flanges and a base plate to give secure mounting to a flat surface. Motor Mounted Unit The Motor Mounted Roloid Gear Pump is available as standard in 7 sizes (90 to 25) giving output flow rates between 3.9L/min to 1052L/min...

Open the catalog to page 5

ROLOID GEAR PUMP PRODUCT AND APPLICATON INFORMATION HST 'T' RANGE ROLOID PUMPS HST Unit The HST Roloid Gear Pumps are available in 3 out of the 7 sizes (50, 40 & 30). They are an enhanced version of the standard gear pump with their design specifically engineered and manufactured for the arduous requirements of lubrication systems used for refrigeration compressors. The HST models cover flow rates between 28L/min to 608L/min and are designed to be configured as either base mounted, motor mounted or flange mounted. HST units come with input and output flanges made to ANSI B16.5 class 150...

Open the catalog to page 6

ROLOID GEAR PUMP ROLOID PUMP Punp Series Pump with ANSI B16.5 Pump Size For Sizes 15 & 20 Consult Application Engineering Pump Type Pump Assembly ] Standard With Metric Shaft Pump Arrangement Base Mounted Flange Mounted Motorised (see dimension table below) Rotor Face Width This designation series may be used only for standard pumps sizes 25 to 90 For non-standard and pump sizes 15 and 20 consult our Application Engineering To ensure correct selection, please contact our Application Engineers Please provide the following information: 1. Discharge (Flow) Rate 3. Details of Operating...

Open the catalog to page 7

ROLOID GEAR PUMP ROLOID PUMP NOMINAL FLOW SELECTION GUIDE 40H - 90H Maximum Facewidth Rotors 15H - 30H Maximum Facewidth Rotors 40H - 90H Minimum Facewidth Rotors 15H - 30H Minimum Facewidth Rotors

Open the catalog to page 8

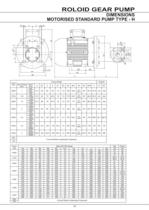

ROLOID GEAR PUMP MOTORISED STANDARD PUMP TYPE - H

Open the catalog to page 12

ROLOID GEAR PUMP PRODUCT SAFETY IMPORTANT Product Safety Information General - The following information is important in ensuring safety. It must be brought to the attention of personnel involved in the selection of power transmission equipment, those responsible for the design of the machinery in which it is to be incorporated and those involved in its installation, use and maintenance. Our equipment will operate safely provided it is selected, installed, used and maintained properly. As with any power transmission equipment proper precautions must be taken as indicated in the following...

Open the catalog to page 15

Radicon Transmission Netherlands & the rest of Europe Elecon. Engineering Anand Sojitra Road Vallabh Vidyanagar SWEDEN & NORWAY Radicon Transmission Amata Nakorn Industrial Estate Tumbol Klongtumru UNITED KINGDOM Lowfields Business Park,

Open the catalog to page 16All Radicon catalogs and technical brochures

-

Series M Helical In-Line

116 Pages

-

BR-Series-AM.

72 Pages

-

adicon-SeriesX

32 Pages

-

BR Series F

117 Pages

-

Radicon Series X Couplings

32 Pages

-

BR Series X Couplings

36 Pages

-

BR Cone Ring Couplings

16 Pages

-

Series J

73 Pages

-

Motor

4 Pages

-

Series E Flyer

4 Pages

-

G series

4 Pages

-

BD

4 Pages

-

Product Brochure radicon

8 Pages

-

Benzlers Screw Jacks

69 Pages

-

Series J - Shaft Mounted Gearbox

15 Pages

-

Radicon Series ET

42 Pages

-

BR Series G

71 Pages

-

Metric

8 Pages

-

Geared Pump

15 Pages

-

Series P Planetary

4 Pages

-

M series

120 Pages

-

Sala Gears

74 Pages

-

Heavy Duty Worm Gear Series ER

15 Pages

-

Screw Jacks

58 Pages

-

Series AM Worm Gear

73 Pages

-

Worm Gear Series AJ

89 Pages

-

Series BS Worm Gear

60 Pages

-

Elflex Flexible Couplings

8 Pages

-

Series H industrial gearboxes

123 Pages

-

SERIE G

71 Pages

-

C series

120 Pages

-

Geared Motor Series K

90 Pages

-

F series

119 Pages

-

Elign Gear Couplings

17 Pages

Archived catalogs

-

Worm Gears Series AH

13 Pages