Catalog excerpts

Coolant Nozzles MAXIMIZING MACHINE TOOL PRODUCTIVITY

Open the catalog to page 1

Coolant Delivery Solutions to Solve Your Production Headaches better finishes and improved accuracy. Improperly applied, it can actually be detrimental to the machining process. Did you ever feel that the coolant system on your machine tools was added as an afterthought? Do you constantly have to improvise and modify nozzles just to get coolant to the tool tip? Are you afraid to run your machines unattended in case a coolant nozzle vibrates out of position and starts a “tool meltdown”? Does coolant seem to be spraying everywhere except where it’s supposed to be spraying? Do you constantly...

Open the catalog to page 2

Choose a nozzle extension that suits your application. Short projections are more compact and are less likely to be knocked out of position by swarf or vibration, while longer extensions are easier to aim, produce a more laminar flow and shoot farther. Some experimentation will be required to achieve the optimum setup. A Word About Pumps Nozzle Extensions The most common coolant pump on CNC machine tools is a single-stage centrifugal pump. They are normally designed to move high volumes of water at low pressures (typically 3 - 20 psi). Multi-stage centrifugal pumps are capable of higher...

Open the catalog to page 3

Back to Table of Contents RATE se n choo You ca ize and ice s ur the orif suit yo ion to xtens e tion! applica New m et balls a ric tapped llow us e with Extens ion Tu bes an d Spray Tips. UNIVERSAL COOLANT NOZZLE FOR CNC MACHINES Converts any NPT or BSPT hole to a fully adjustable nozzle n Hits any target above mounting plane n Adjusts easily for accurate coolant placement n Difficult to accidentally knock out of adjustment n Choose larger orifices for maximum flow n Choose smaller orifices when using multiple nozzles n Choose tapped ball, if you need to quickly plug the orifice (setscrew...

Open the catalog to page 4

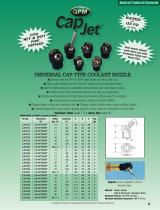

Back to Table of Contents New m et balls a ric tapped llow us e with Extens ion Tu bes an d Spray Tips. UNIVERSAL CAP-TYPE COOLANT NOZZLE Screws onto any NPT or BSPT pipe nipple just like a pipe cap n Same great features as the TurretJet, except with female pipe thread n Ideal for high production, dedicated machine tools with rigid coolant piping n Choose orifice size and nozzle extension to suit your application n Choose short extensions for tight spaces and where stringy swarf is a problem n Long extensions make aiming a breeze and shoot farther n Choose larger orifices for maximum flow n...

Open the catalog to page 5

Back to Table of Contents DIMENSIONS IN INCHES (except as noted) SCREW-IN, BOLT TYPE COOLANT NOZZLE n Screws into a threaded coolant port just like a bolt n ±35 degrees of adjustment either side of centerline n Rated to 150 PSI (10 bar) n Sizes available to fit almost every machine or tool holder n Choose the orifice diameter and projection length to suit your application n Choose larger orifices for maximum flow n Choose smaller orifices when using multiple nozzles n Choose tapped ball if you need to quickly plug the orifice (setscrew included) or to use with Extension Tubes (page 17) or...

Open the catalog to page 6

Back to Table of Contents SCREW-IN, FLUSH MOUNT COOLANT NOZZLE Screws into an NPT or BSPT hole just like a flush plug I 35 degrees adjustment either side of centerline I Rated to 150 psi max I Ideal for machining applications where nozzle projections must be minimized I Material: Body - Acetal Ball - Stainless Steel Maximum Operating Temperature: 160˚F (70˚C) Maximum Pressure: 150 PSI (10 bar) Simply insert the end of allen wrench (included) into the hole in the stainless ball until it engages the hex hole in the acetal body, then tighten the PlugJet into the tapped hole until the body is...

Open the catalog to page 7

Back to Table of Contents COOLANT NOZZLE FOR VERTICAL & HORIZONTAL MACHINING CENTERS n Adjusts from full shutoff to fine fan spray to direct stream n Aimable from zero to 90° with 360° sweep n Stays put (doesn’t vibrate out of place) n No interference problems with clamps, fixtures or swarf n Fits NPT and BSPT threads n Rated to 100 psi (6.7 bar) maximum DIMENSIONS IN INCHES Part No. – Recommended coolant filtration - 100 microns – Material: Acetal Maximum Pressure: 100 PSI (6.7 bar) Maximum Operating Temperature: 160°F (70°C) MillJets shown in use at various angles and spray widths....

Open the catalog to page 8

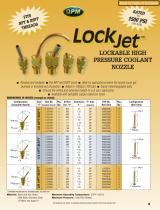

Back to Table of Contents LOCKABLE HIGH PRESSURE COOLANT NOZZLE Aimable and lockable n Fits NPT and BSPT ports n Ideal for applications where the nozzle could get bumped or knocked out of position n Rated to 1500psi (100 bar) n Easily interchangeable balls n Choose the orifice and extension length to suit your application n Available with bendable copper extension tubes DIMENSIONS IN INCHES (except as noted) Configuration (Complete Nozzle) F Size Part No. Pkg. Orifice Extension "F" max "E" Complete Nozzle* Qty. Dia. "d" "L" (degrees) Part No. Ball Only Configuration (Ball Only) * Complete...

Open the catalog to page 9

Back to Table of Contents Pipe fit Sizes SPT B NPT &ADS THRE ble in Availa r Brass o el ss Ste Stainle Availab le with extend ed spra y tip to shoo t farthe s r HIGH PRESSURE COOLANT NOZZLE FOR CNC MACHINES n High velocity coolant stream increases productivity and tool life in machining and grinding operations n Also ideal for low pressure applications where abrasive swarf is a problem n Hits any target above mounting plane n Interchangeable spray tips available! n Easy to aim n Choose short extensions for tight spaces like CNC Turning Centers and Screw Machines n Choose stainless steel...

Open the catalog to page 10

Back to Table of Contents Ordering Information: 1. Determine the port thread size required for your machine tool. 2. Choose nozzle body material (brass for general purpose, stainless steel when using cutting oils not compatible with cuprous alloys). 3. Determine orifice diameter required to match your pump’s capacity at the desired pressure (refer to table on page 2). 4. Choose the extension length “L” to suit your application (longer extensions give more laminar flow, aim easily and shoot farther, while short extensions are ideal for tight spaces or where stringy swarf is a problem)....

Open the catalog to page 11Archived catalogs

-

JETBOLT

1 Pages

-

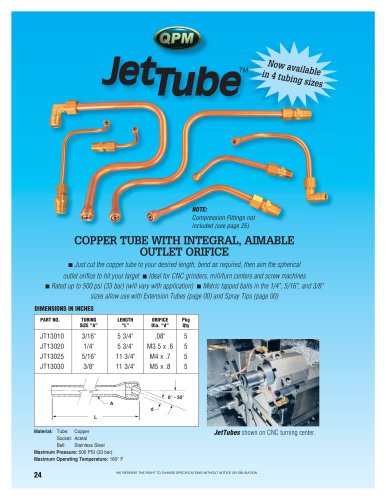

JET TUBE

1 Pages

-

BORE PLUG

1 Pages

-

Ball Valve

1 Pages