Catalog excerpts

Crystallize Your Visions Crystal Growing Systems

Open the catalog to page 1

Crystal Growing Systems 02 Crystals for the semiconductor industry 02 Crystals for the photovoltaic industry 02 From silica sand to high-tech products 09 Individual solutions for individual customers 10 Systems in the „EKZ" series - Czochralski systems (CZ) 12 Systems in the „ Multicrystallizer" series - vertical gradient freeze systems (VGF) 16 Systems in the „Multigeneration" series - edge-defined film-fed growth systems (EFG) 18 Systems in the HTCVD" series - chemical vapor deposition systems (CVD) 20 Systems in the „FZ" series - float zone systems (FZ) 22 Systems in the „Kronos" series...

Open the catalog to page 2

Semiconductor Systems Division Setting up benchmarks as a global market leader In the Semiconductor Systems Division, all PVA TePla systems are concentrated for customers from the semiconductor industry. The main areas covered here are systems for crystal growing, for plasma applications and for quality control of high-quality materials and semiconductor devices. Crystal growing systems for wafer manufacturers Rod-shaped silicon monocrystals, also called ingots, are cut into thin disks. Known as wafers in the semiconductor industry, they are the basic material for semiconductor production....

Open the catalog to page 3

Solar Systems Division Systems for high-quality Crystals In the Solar Systems Division systems for processing high quality crystals are produced in addition to a number of other products. PVA TePla AG is able to provide all relevant processes, especially in the area of growing mono- and multicrystalline silicon crystals. The Solar Systems Division primarily builds systems for creating extremely high-quality silicon crystals and blocks. These crystals are vital components in the photovoltaics value chain. In the coming years, rising raw material prices, increasing scarcity of fossil fuel...

Open the catalog to page 4

PVA TePla: Crystal growing systems at a glance PVA TePla AG is the leading crystal growing system provider for hightech industries. The company has all industrially relevant methods for crystal growing, particularly for growing mono- and multicrystalline silicon crystals. Integrated into the work of several research institutes, the company acts as a provider of high-quality systems and is also actively involved in the latest technological developments in the area of crystal growing. We constantly impress our industrial customers with our crucial technological edge and individually devised...

Open the catalog to page 5

Crystal Growing Systems Crystals for the next generation The highly innovative chip industry requires new materials and technologies for higher processing power, faster connections and higher memory capacity Crystals for the semiconductor industry However, all this can only be achieved with increasingly powerful semiconductor components. Therefore the requirements for perfectness of crystalline semiconductor materials, wafer dimensions and reproducibility in manufacture will continue to increase. This fact was recognized by Gordon Moore (co-founder of Intel) back in 1965, just a few years...

Open the catalog to page 6

Crystals for optoelectronics The days of the traditional light bulb are numbered. In February 2007 Australia became the first country to , announce a ban on the sale of conventional light bulbs. In doing this, Australia intends to help reduce greenhouse gases (CO2). „If the whole world switches to these bulbs today, we would reduce our consumption of electricity by an amount equal to five times Australia‘s annual consumption of electricity“ says Malcolm , Turnbull (Australian Environment Minister). The alternative to the light bulb is the light-emitting semiconductor diode. Since the...

Open the catalog to page 8

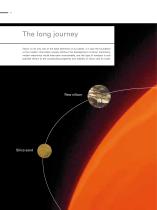

The long journey Silicon is not only one of the base elements of our planet, it is also the foundation of the modern information society. Without the development of silicon transistors, modern electronics would have been inconceivable, and this type of transistor is only possible thanks to the outstanding properties and stability of silicon and its oxide. Silica sand

Open the catalog to page 10

Pure silicon View into the crucible with molten silicon

Open the catalog to page 11

The origin is the sand To obtain pure silicon, the oxygen must be extracted from silica sand (SiO2) with the help of carbon. As silicon and oxygen are very closely related atomically, the carbon and oxygen in silica sand only combine to form carbon dioxide at very high temperatures (approx.1,800°C). The carbon dioxide is drained off and silicon is left behind. This process is highly energyintensive, requiring approx. 14 kWh per kg of raw silicon. Raw silicon extracted in this way still contains approx. 1% impurities. However, a purity level of at least 0.0000001% (1ppb) is required. The raw...

Open the catalog to page 12

From silica sand to high-tech products Wafers The silicon monocrystals are subjected to mechanical circular grinding and markings for identifying the crystal orientations. The monocrystals are cut into thin discs using diamond or wire saws. To compensate for irregularities, the Si discs are subjected to coplanar grinding with fine-grained grinding discs made of diamond. Surface defects are also etched away by means of plasma in order to obtain a crystallographically perfect surface. The resultant roughening of the wafer is removed by polishing in cleanrooms. Chips Computer chips are...

Open the catalog to page 13

Individual solutions for individual customers

Open the catalog to page 14

As an SME in the PVA TePla AG Group, our main priority is to offer customers solutions for their complex technological requirements. We see our customers as partners to achieve the following together in future: eveloping and implementing d individual solutions aintaining close contact from m the offer phase through to system commissioning and beyond eveloping procedures and d processes as well as implementing process optimizations. Quality awareness, adherence to deadlines and technical expertise set us apart as one of the world‘s leading companies in the sector.

Open the catalog to page 15

Semiconductor Systems Solar Systems

Open the catalog to page 16

„EKZ“ series for the semiconductor and solar industry The CZochralski method With these systems, monocrystalline materials are produced according to the „CZ method“ This is also known as „crystal pulling“ or „pulling from the melt“ . . The method In the CZ process, high-purity, polycrystalline silicon is put into the quartz crucible of a monocrystal growing system. Next, the process room is evacuated and the silicon is then melted down in an argon controlled atmosphere via resistive heating. After temperature stabilization of the melt (approx. 1420°C), a rotating monocrystalline silicon...

Open the catalog to page 17All PVA TePla Group catalogs and technical brochures

-

SSH Smart Sinter HIP

4 Pages

-

SiCube

2 Pages

-

baSiC-T

2 Pages

-

SR Series

2 Pages

-

FZ-30

2 Pages

-

FZ 14-M

2 Pages

-

PVA TePla - CCIC

6 Pages

-

Systems of PVA TePla

12 Pages

-

OKZ 300

2 Pages

-

EKZ 3000

2 Pages

-

SolarCrystallizer 22

2 Pages

-

EKZ 3500

2 Pages

-

CGS-Lab

2 Pages

-

EKZ 2700

2 Pages