Catalog excerpts

– The most advanced technology for consistent homogenous products • Single acting mechanical seal (cartridge design) • GMP-compliant design • Inlet/outlet connections: hygienic thread to DIN 11851-1 • Product contact surfaces: Ra ≤ 0,4 μm (pharma finish) It is marked out by first-class production performance and exceptional hygiene levels. Optimized design of the product chamber eliminates dead zones and the machine is simple and easy to clean. It is ideal for processing even the most s ensitive products and the wide range of options ensures extreme flexibility. • Tri-clamp and flange connections • Heated/cooled inlets/outlets • Explosion-proof design (ATEX) • Double acting mechanical seal Applications • Mayonnaise, ketchup, dressing Installed Dimensions [mm] power Length Width Height [kW] A B C GMP-compliant aseptic design Optimized product chamber Optimized sealing technology High throughput High performance Fully CIP/SIP-compatible Product infeed Product discharge technical data subject to modification When dispersing suspensions, powder solids are wetted, de-agglomerated and homogenized until the desired product quality is achieved. The h omogenizer is designed for use inline. Based on the principle of a multi-chamber rotor/ stator system, the Inline Homogenizer is suitable for emulsification and suspension of fluid products. Product is introduced via a pump into the first chamber, where a special mixer/feeder combination premixes the product and feeds it to the • Ointments, creams, emulsions, suspensions toothed rotor/stator system – a high-performance homogenizer. The product is then sheared: the high level of shear forces in the shear gap and high-energy turbulence at the rotor channel outfeed ensure excellent product quality. When p rocessing emulsions, this unit can achieve particle sizes down to 1 µm with a fine distribution. The FrymaKoruma Inline Homogenizer offers a clean, high-performance solution at the highest technical level: Paper and printing ink from sustainable sources Romaco FrymaKoruma Sales FrymaKoruma GmbH Fischerstraße 10 79395 Neuenburg Germany Tel. +49 (0)7631 7067 0 Fax +49 (0)7631 7067 29 frymakoruma@romaco.com www.frymakoruma.com Standard version F rymaKoruma Inline Homogenizer T h e m o s t a dva n c e d t e c h n o l ogy fo r c o n s i s tent

Open the catalog to page 1All ProXES GmbH catalogs and technical brochures

-

FrymaKoruma Vacuum Deaerator

3 Pages

-

ProTec

3 Pages

-

FrymaKoruma Mills

3 Pages

-

Vacuum Deaerator

3 Pages

-

VME

3 Pages

-

MaxxD

3 Pages

-

Stirrer bead mill 2014

4 Pages

-

Dinex

4 Pages

-

CoBall-Mill

4 Pages

-

InMixx

4 Pages

-

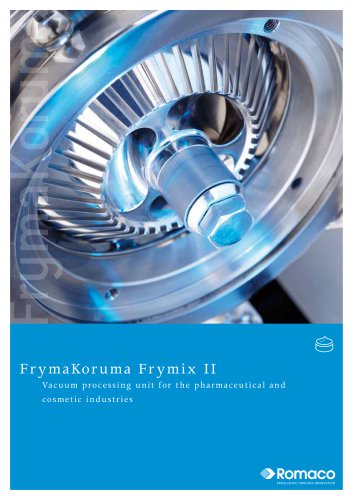

Frymix II

4 Pages