Website:

PROTEM

Website:

PROTEM

Group: ttng-hd

Catalog excerpts

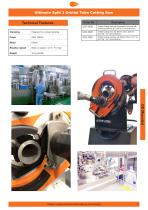

ULTIMASTER Series Ultimate Split Orbital Tube Cutting Saws ULTIMASTER orbital pipe cutting Saws are the ideal solution for your on-site jobs. These machines are also perfectly suited for prefabrication workplaces and they can be used under severe conditions (extreme temperatures, high humidity, ionizing radiations) Suitable for all types of steel: mild steel, stainless steel, duplex, super duplex, inconel, hastelloy, aluminium, copper, titanium, etc. Pneumatic or electric drives are available for all machines in the Ultimate Split series. Robust and reliable, it can be used on-site, in the workshop or in extreme environments. Cold Cutting Process. No Heat Affected Zone Pictures, drawings and technical information are not contractual

Open the catalog to page 1

Ultimate Split 3 Orbital Tube Cutting Saw Standard Capacity: 0.196" - 3.5" (5 mm - 88.9 mm) The Ultimate Split 3 orbital cutting machine is used for cutting tubes made of virtually all materials having diameters ranging from 0.196“ (5 mm) to 3.5“ (88.9 mm) and wallthicknesses ranging from 0.04“ (1 mm) to 0.27“ (7 mm). It enables the cutting of pipes without any deformation thanks to its concentric clamping system. The cut is absolutely perpendicular and burr-free. The adjustment to the different diameters is very simple and fast. The Ultimate Split 3 is the orbital cutting saw you need for...

Open the catalog to page 2

Ultimate Split 3 Orbital Tube Cutting Saw Technical Features: Orbital Cutting Saw with Pneumatic Drive and with Clamping Jaws for Ø 0.196"-3.5" (5mm-88.9mm) Expansion by manual clamping Orbital Cutting Saw with Electric Drive 220V for Ø 0.196" -3.5" (5mm-88.9mm) Orbital Cutting machine with Electric Drive 110 V for Ø 0.196" -3.5" (5mm-88.9mm) Rotation Speed Pictures, drawings and technical information are not contractual

Open the catalog to page 3

Ultimate Split 6 Orbital Tube Cutting Saw Standard Capacity: 0.5" - 6.625" (12.7 mm - 168.3 mm) The Ultimate Split 6 orbital cutting machine is used for cutting tubes made of virtually all materials having diameters ranging from 0.5“ (12.7 mm) to 6“ (168 mm) and wallthicknesses ranging from 0.04“ (1 mm) to 0.59“ (15 mm). It enables the cutting of pipes without any deformation thanks to its concentric clamping system. The cut is absolutely perpendicular and burr-free. The adjustment to the different diameters is very simple and fast. The Ultimate Split 6 is the orbital cutting saw you need...

Open the catalog to page 4

Ultimate Split 6 Orbital Tube Cutting Saw Technical Features: Orbital Cutting Saw US6 for Ø 0.5" - 6.625" (12.7mm - 168.3mm) with pneumatic drive. Manual expansion clamping Orbital Cutting Saw US6 for Ø 0.5" - 6.625" (12.7mm - 168.3mm) with electric drive 220V. Orbital Cutting Saw US6 for Ø 0.5" - 6.625" (12.7mm - 168.3mm) with cordless electric drive 220V. Orbital Cutting Saw US6 for Ø 0.5" - 6.625" (12.7mm - 168.3mm) with electric drive 110V. Rotation Speed Orbital Cutting Saw US6 for Ø 0.5" - 6.625" (12.7mm - 168.3mm) with cordless electric drive 110V. Pictures, drawings and technical...

Open the catalog to page 5

Ultimate Split 12 Orbital Tube Cutting Saw Standard Capacity: 6“ - 12“ (168.3 mm - 323.9 mm) The Ultimate Split 12 orbital cutting machine is used for cutting tubes made of virtually all materials having diameters ranging from 6“ (168.3 mm) to 12“ (323.9 mm) and wallthicknesses ranging from 0.04“ (1 mm) to 0.59“ (15 mm). It enables the cutting of pipes without any deformation thanks to its concentric clamping system. The cut is absolutely perpendicular and burr-free. The adjustment to the different diameters is very simple and fast. The Ultimate Split 12 is the orbital cutting saw you need...

Open the catalog to page 6

Ultimate Split 12 Orbital Tube Cutting Saw Technical Features: Clamping Orbital Cutting Saw US12 for Ø 6“ - 12“ (168.3 mm - 323.9 mm) with electric drive 220V. Orbital Cutting Saw US12 for Ø 6“ - 12“ (168.3 mm - 323.9 mm) with electric drive 110V. Rotation Speed Pictures, drawings and technical information are not contrac

Open the catalog to page 7

Ultimate Split US3, US6 & US12 Orbital Cutting Saw Options 1. Roller conveyor - downstream module - Length 1500 mm - Maximum load capacity of 200 kg - Height adjustable for different pipe diameters - Manual screw operating system - Simple installation Description Roller conveyor - downstream module 2. Roller conveyor - upstream module - Length 1500 mm - Maximum load capacity of 200 kg - Fixed height - Simple installation Description Roller conveyor - upstream module 3. Roller conveyor - additional module - Length 1500 mm - Maximum load capacity of 200 kg - Fixed height - Simple installation...

Open the catalog to page 8

Ultimate Split US3, US6 & US12 Orbital Cutting Saw Options Cutting Blades: Order No. Saw blade - 80 teeth for wallthickness 0.039" - 0.118" (1-3mm) Saw blade - 54 teeth for wallthickness 0.078" - 0.275" (2-7mm) Saw blade - 34 teeth for wallthickness 0.196" - 0.393" (5-10mm) Saw Blade - 100 teeth for wallthickness 0.02"-0.059" (0.5-1.5mm) Saw Blade - 70 teeth for wallthickness 0.039"-0.118" (1mm-3mm) Saw Blade - 64 teeth for wallthickness 0.118"-0.276" (3mm-7mm) Saw Blade - 44 teeth for wallthickness 0.276"-0.472" (7mm-12mm) Saw Blade - 34 teeth for wallthickness 0.472"-0.591" (12mm-15mm)...

Open the catalog to page 9

ULTIMASTER SERIES UG1 Tungsten Electrode Sharpener & Grinder Pictures, drawings and technical information are not contractual

Open the catalog to page 10

UG1 Tungsten Electrode Sharpener & Grinder TUNGSTENE ELECTRODE: SHARPENING ; POINTING ; CUTTING MACHINE FOR TIG WELDING GTAW (Gas tungsten arc welding), also called TIG (tungsten inert gas) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. When it comes to GTAW/TIG welding, tungsten electrodes are the most important part of the application. The tungsten electrode is the crucial carrier in the welding process and must be ground and cut properly. An improperly prepared electrode leads to arc wander, splitting, shedding and inconsistencies....

Open the catalog to page 11All PROTEM catalogs and technical brochures

-

Welding Preparation - Turkish

100 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

Boring Bar

1 Pages

-

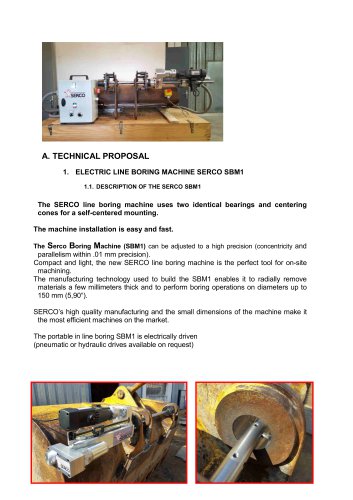

Serco SBM1

4 Pages