Website:

PROTEM

Website:

PROTEM

Group: ttng-hd

Catalog excerpts

CTA Series High Speed Cutting and Beveling Machines The electric motors, up to 50 kW for large diameters, supply the necessary power to cut and bevel tubes with heavy wall thicknesses. The "Brushless" motors used by PROTEM guarantee a very high machining accuracy and control the feed and rotation speeds. The machine is designed with a double external clamping of the tubes upstream and downstream of the internal part of the machine. The jack thrust and clamping system design provide a firm and concentric clamping on the outside diameter of the tube. The chips conveyor is automatically operated by the CTA control system. As soon as the tool holder plate starts rotating, the chips conveyor start to operate. The chips conveyor keeps the internal part of the machine clean. The immediate removal of the chips toward the outside protects the machine from any chip that could damage the quality of the machining operation or shorten the lifetime of the cutting tool bits. The lifting table option can be used with the complete range of CTA machines. The lifting table is positioned under the CTA structure. It adjusts the machine to the tube diameter. This option is necessary if the front and back conveyors (to be supplied by the enduser or delivered as an option upon request) are not equipped with a height adjustment system. CTA Series Machining Capacities All the front / back conveyors can be used with the complete range of CTA machines. The height adjustment conveyor is designed to align the different diameters of tubes with the cutting machine axis. It can be supplied with different lengths; 6 meters (20'), 8 meters (26'), 10 meteres (33') or 12 meters (39'). The tubes can be conveyed manually or with motorized rollers. (1422.4mm - 1828.8mm) Pictures, drawings and technic

Open the catalog to page 1

CTA Series High Speed Cutting and Beveling Machines Standard Capacity: 1“ - 72“ (25.4mm - 1828.8mm) depending on the model The Protem CTA machines are the equipment you will need for your production and prefabrication requirements. The PROTEM CTA – High speed cutting and beveling machines save space in your workshops and can be integrated on your production lines for unmatched results. Tubes and pipes with OD Ø ranging from 1“ - 72“ (25.4mm - 1828.8mm) will be cut and beveled within just a few seconds. Larger models are available upon request. The machining unit is made of a welded...

Open the catalog to page 2

CTA1-4 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Tool-plate rotation speed Rotation motor drive power Machining tool feed speed Pneumatic cylinders Cylinder pressure Electricity supply High Speed Cutting & Beveling Machine for Ø 1" - 4.5" (25.4mm - 114.3mm) CTA2-6 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Standard jaw diameter Min = Ø < 11.02” (280 mm) Max = Ø > 18.5” (470 mm) Additional jaw diameters Min = Ø < 5.9” (150 mm) Max = Ø > 13.38” (340 mm) Rotation motor drive power Pneumatic cylinders...

Open the catalog to page 3

CTA2-12 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Standard jaw diameter Min = Ø 6" (173mm) Max = Ø12" (323mm) Additional jaw diameters Min = Ø 2" (50.8mm) Max = Ø8" (212mm) Tool-plate rotation speed Rotation motor drive power Machining tool feed speed Pneumatic cylinders Cylinder pressure Electricity supply High Speed Cutting & Beveling Machine for Ø 2.374" - 12.75" (60.3mm - 323.9mm) CTA6-16 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Standard jaw diameter Min = Ø < 11.02” (280 mm) Max = Ø > 18.5”...

Open the catalog to page 4

CTA12-24 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Standard jaw diameter Min = Ø 20" (508mm) Max = Ø 24" (610mm) Additional jaw diameters Min = Ø 12" (323mm) Max = Ø 20" (508mm) Tool-plate rotation speed Rotation motor drive power Machining tool feed speed Pneumatic cylinders Cylinder pressure Electricity supply High Speed Cutting & Beveling Machine for Ø 12.75" - 24" (323.9mm - 610mm) CTA16-30 High Speed Cutting and Beveling Machine Technical Features: Maximum machining thickness Standard jaw diameter Min = Ø < 26” (660 mm) Max = Ø > 32.28”...

Open the catalog to page 5

CTA24-36 High Speed Cutting and Beveling Machine Standard Capacity: 24“ - 36“ (610mm - 914.4mm) Description High Speed Cutting & Beveling Machine for Ø 24" - 36" (610mm - 914.4mm) CTA30-42 High Speed Cutting and Beveling Machine Standard Capacity: 30“ - 42“ (762mm - 1066.8mm) Description High Speed Cutting & Beveling Machine for Ø 30“ - 42“ (762mm - 1066.8mm) CTA42-56 High Speed Cutting and Beveling Machine Standard Capacity: 42“ - 56“ (1066.8mm - 1422.4mm) Description High Speed Cutting & Beveling Machine for Ø 42“ - 56“ (1066.8mm - 1422.4mm) CTA56-72 High Speed Cutting and Beveling...

Open the catalog to page 6

CTA Series High Speed Cutting and Beveling Machines The machine is delivered with an electric panel in conformity with the EC Standards. On the face of the panel, several switches and a screen to operate the machine are available. The end user can use the manual mode. The control panel allows the user to control all essential functions: Clamp /Unlock, Slow / Fast Machining, Start / Stop Machine Manual / Automatic, Emergency Stop. Automatic clamping system The automatic and pneumatic clamping systems set the concentricity of the tube. The machining is performed between both clamping systems....

Open the catalog to page 7

CTA Series High Speed Cutting and Beveling Machines Tube Storage Table All the feeding tube conveyors or storage tube conveyors can be easily connected to any machine in the CTA series. The length of the feeding or storage tube conveyor is adapted to the length of the tube conveyor. Lifting table The optional lifting table can be used with any version of the CTA machine. The lifting table is positioned under the CTA structure. Its purpose is to align the axis tool holder plate with the tube to be machined which must be set on a fixed tube conveyor. This option saves time and helps to...

Open the catalog to page 8All PROTEM catalogs and technical brochures

-

Welding Preparation - Turkish

100 Pages

-

Orbital Cutting Saws

12 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

Boring Bar

1 Pages

-

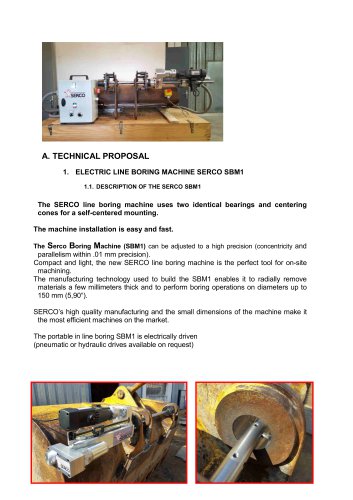

Serco SBM1

4 Pages