Website:

PROTEM

Website:

PROTEM

Group: ttng-hd

Catalog excerpts

THE FUTURE OF ON SITE MACHINING XP Series Portable Equipment for Facing Flanges and Valves SERCO XP machines are designed for use in difficult and restrictive conditions. As parallelism and concentricity settings are independent, only two stages are needed to set up the SERCO XP machines. Independent settings mean that the flatness does not need to be adjusted again after the concentricity has been set. Machines can be set-up easily. Once the machine is in position, adjustments can be made effortlessly and achieve high levels of accuracy (0.01 mm). Rugged design and easy transport of the machine for integration of the machine into a production line SERCO machines have been designed for use under extremely difficult and restrictive conditions. SERCO XP machines can be set up easily in extremely confined spaces and in all positions. Their light weight also means that they can be installed and used by a single operator. With a precision of 0.01 mm and a surface finish quality of Ra 1.6 - 12.7, SERCO machines offer the best possible performances for your facing operations. SERCO XP machines are positioned and held in place by a column/arm system that clamps on to the outside of the part to be machined. Pictures, drawings and technical information are not contractual

Open the catalog to page 1

THE FUTURE OF ON SITE MACHINING XP Series Portable Equipment for Facing Flanges and Valves Standard Capacity: 0 mm - 3200 mm (0“ - 125.9“) The Serco XP machines all work on the same principle. They are set up and fixed in place by a column/arm system. This clamping principle allows high precision performance of internal machining operations. The XP machine setup is fast and easy. The design allows for independent adjustment of the concentricity and parallelism to reach a precision of 1/100 mm with a surface finish of 1.6 Ra.to Ra 12.7. Mobile Powerful Machining Equipment Easy and Safe use...

Open the catalog to page 2

THE FUTURE OF ON SITE MACHINING XP400NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 400 mm (0.393” – 15.7”) Surfacing of all types of flanges: 10 to 400 mm (0.393” 15.7”). The SERCO XP 400 is the most compact machine in the series. Its weight is reduced to a strict minimum and enables it to be handled and set up by a single operator, without any need for extra handling devices. These features make the machine ideal for all surfacing operations on diameters from 10 to 400 mm (15.7”). Radial feed Maximum drive motor power at 6 bars Drive motor speed under no-load...

Open the catalog to page 3

THE FUTURE OF ON SITE MACHINING XP600NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 600 mm (0.39” – 23.6”) Surfacing of all types of flanges: 10 to 600 mm (0.393” - 23.6”). The SERCO XP600NG is the best compromise between machining capacities, light weight and size for a flange facing machine. Its weight is reduced to a strict minimum and enables to be handled and set up by a single operator, without any need for extra handling devices. The machine can perform facing operations as well RTJ grooves machining through an inclinable head as an option This features...

Open the catalog to page 4

THE FUTURE OF ON SITE MACHINING XP900NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 900 mm (0.39” – 35.43”) Surfacing of all types of flanges: 10 to 900 mm (0.393” - 35.4”). The SERCO XP900NG is a machine able to reach a 900 mm machining diameter and being set up on site by two operators without any need for extra handling devices. A powerful motorization allow the SERCO XP900NG to perform flange maintenance in a minimum of time. The machine can perform facing operations as well RTJ grooves machining through an inclinable head as an option This features make the...

Open the catalog to page 5

THE FUTURE OF ON SITE MACHINING XP1200 Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 1200 mm (0.39” – 47.2”) Facing of all types of flanges: 10 to 1200 mm (0.39” - 47.2”) The SERCO XP 1200 machine uses a machining head that only possesses a radial feed movement. This means that it is more compact than the TU type machines for operations where boring is not required. 4 removable arms adjustable over 360° enable the XP 1200 to be mounted on the dowel pin bores of any type of flange for performing facing operations from 10 to 1200 mm (47.2”). Radial feed Maximum...

Open the catalog to page 6

THE FUTURE OF ON SITE MACHINING XP1800NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 1800 mm (0.39” – 70.8”) Surfacing of all types of flanges: 10 to 1800 mm (0.39” to 70.8”). The SERCO XP1800NG machine is designed on the same principles as the XP1200, with a radial movement machining head. The four mobile clamping arms have been reinforced to maintain the rigidity of the unit when machining diameters up to 1800 mm (70.8”). Radial feed Maximum drive motor power at 6 bars Drive motor speed under no-load conditions Air supply pressure in bars Weight (approximate)...

Open the catalog to page 7

THE FUTURE OF ON SITE MACHINING XP2000NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 2000 mm (0.39” – 78.74”) Surfacing of all types of flanges from 10 to 2000 mm (0.39” to 78.74”). Just like the XP 1200 and XP1800NG models, the SERCO XP 2000 is equipped with a radialfeed machining head and four removable clamping arms the position of which can be adjusted depending on the application. SERCO engineers have paid particular attention to maintaining the rigidity of the assembly in order to guarantee high precision machining on surfaces up to 2000 mm (78.74”) in...

Open the catalog to page 8

THE FUTURE OF ON SITE MACHINING XP2200NG Portable Equipment for Facing Flanges and Valves Standard Capacity: 10 - 2200 mm (0.39” – 86.6”) Surfacing of all types of flanges: 10 to 2200 mm (0.39” to 86.6”). Using the same machining head as the smaller versions, the SERCO XP 2200 has been designed for machining even larger diameters. To do this, an intermediate ring has been added to prevent any inadvertent movement on the flange facing attachment. In this way, the arm is guided perfectly, which enables the XP 2200 to guarantee accuracies similar to those obtained with other equipment in the...

Open the catalog to page 9All PROTEM catalogs and technical brochures

-

Welding Preparation - Turkish

100 Pages

-

Orbital Cutting Saws

12 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

Boring Bar

1 Pages

-

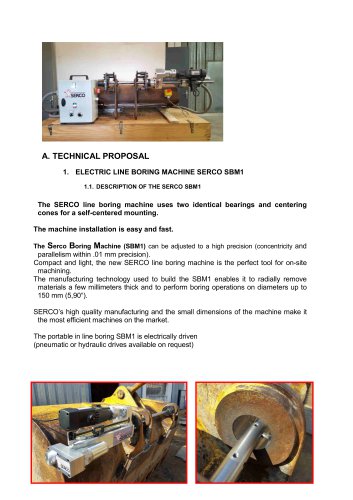

Serco SBM1

4 Pages