Website:

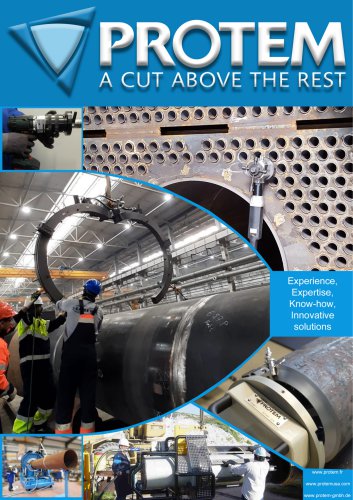

PROTEM

Website:

PROTEM

Group: High Precision Machining Equipment

Catalog excerpts

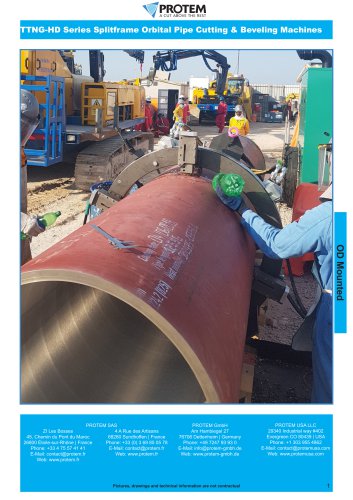

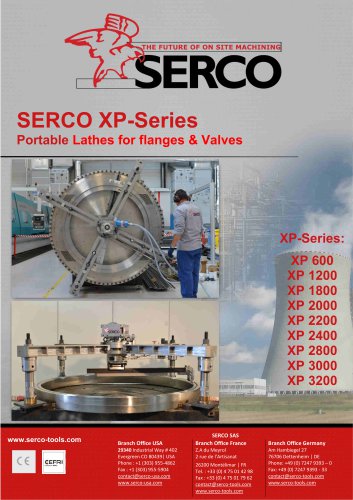

THE FUTURE OF ON SITE MACHINING Cutting Machine for Heat Exchanger Tubes Standard Capacity: 59.05" - 118.11" (1500mm - 3000mm) The machine is used during the heat exchanger manufacturing process when they pass the tubes across the tube sheet. The tubes that are not the same length out of the tube sheet will be cut to 0.197" (5mm) from the tube sheet. The tubes are not clamped on the tube sheet, there is a small gap of 0.0039" (0.1 mm). The machine is based on a frame of XP machine but without a machining head. It uses two milling heads with saw blades. The arms with milling heads perform the cut of all the tubes on the same tube sheet with a 180° rotation. After the cut, a PROTEM SM8 is used to face the tubes precisely. By hand (with a grinder), they needed more than 3 days to make all the cuts and now, with the machine, less than 1 day is enough. Technical Features: O.D. of the pipe Pipe wall thickness Length of fixed legs (B) Distance between pipe centers (D) Pipe material Diameter of the raised part on the center of the tube-plate (E) Height of the raised part on the center of the tube-plate (F) Height of the pipe before cutting Height of the pipe after cutting Pictures, drawings and technical information are not contractua

Open the catalog to page 1All PROTEM catalogs and technical brochures

-

Tube and Pipe End prep equipment

166 Pages

-

Tube and Pipe Beveling Machines

53 Pages

-

Nuclear catalogue

427 Pages

-

Orbital Cutting Saws

12 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

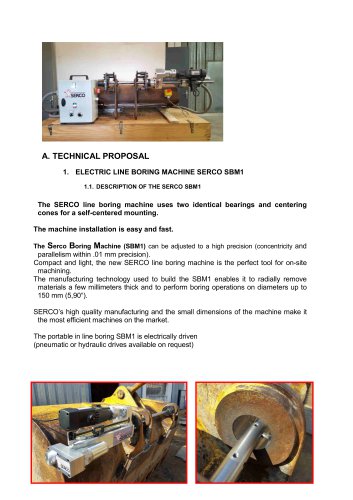

Boring Bar

1 Pages

-

Serco SBM1

4 Pages