Catalog excerpts

Dock leveller with hinge lip PS Operating and maintenance manual Technical modifications reserved

Open the catalog to page 1

Dock leveller with hinge lip PS Technical modifications reserved

Open the catalog to page 2

Dock leveller with hinge lip PS Operating manual 1. Introduction The drawings in this manual are for demonstration purpose only. This manual refers only to the PS-type dock leveller with hinge lip. Other types of dock levellers are described in separate manuals. This manual contains additional hints and notes indicated with the following graphic symbols:: Relates to situations hazardous to health and life and carrying the risk of substantial material damage. Important instructions and information for the operator. In case of any doubts, the purchaser of the device should consult a...

Open the catalog to page 3

Dock leveller with hinge lip PS 2. Application 2.1 Dock leveller description Nominal length Nominal width Lip length Leveller height Upper operating range Lower operating range The dock leveller is used to compensate height and distance differences between the vehicle deck and the warehouse floor surface, ensuring quick and smooth loading/unloading of trucks. The PS-type dock leveller consists of a platform whose rear part is fixed with a hinge to the warehouse ramp at floor level. The platform is equipped with a hinge lip at the front. For reloading operations this lip is opened and...

Open the catalog to page 4

Dock leveller with hinge lip PS The leveller can be set in its rest position only when the lip is positioned vertically. In this position, the leveller can be subject to load that equals its nominal capacity. Leveller elements that may create any hazard are marked as follows: Black and yellow stripe indicates tripping hazard. Orange marking on the leveller plate and its frame indicates that the leveller tilts beyond the permissible operating angle of the platform, i.e. ±12.5% (approx. ±7º). Optionally, the dock leveller can be delivered with three type of lip: Dock leveller with...

Open the catalog to page 5

Dock leveller with hinge lip PS 2.1.1 Use for the intended purpose Using the leveller in accordance with general guidelines on safe operation (see chapter 4. General guidelines on safe operation) shall be considered use for the intended purpose. 2.1.2 Misuse Using the leveller not in accordance with the general guidelines on safe operation (see chapter 4. General guidelines on safe operation) shall be considered use against the intended purpose. 2.2 Control system The dock leveller is lifted hydraulically. The hydraulic unit, lifting cylinders and the extension cylinder are located under...

Open the catalog to page 6

Dock leveller with hinge lip PS Releasing the ‘LIFT’ button will cause automatic descend of the loading leveller to its rest position. If the ‘LIFT’ button is released too early (with the leveller still below the warehouse ramp level), the leveller shall not proceed to its rest position but it will assume its lowest position instead. ‘AUTO’ return button (OPTION) This is a button located under the ‘LIFT’ button. Brief push of this button causes the dock leveller to return to its rest position. The leveller is raised to its highest position with the lip unfolding; then the leveller is...

Open the catalog to page 7

Dock leveller with hinge lip PS 3.3 Daily start-up Before the first start-up of the dock leveller, the device should be inspected for safety reasons. If no problems are noticed, the leveller can be started. In order to do so: Set the main switch in the ‘1’ position, wait 5 seconds to allow an internal trial run to be performed, then complete one operating cycle of the leveller to check its functions. The leveller is ready for daily operation. Warning! If during operation (or before the leveller is started) any incorrect functioning or fault is found, the yellow and red main switch must be...

Open the catalog to page 8

Dock leveller with hinge lip PS 3.5.2 Placing (lowering) the dock leveller onto the vehicle deck Warning! When lifting and lowering the dock leveller, no persons are allowed within the leveller operating area. Whenever unauthorized persons enter the said area, set the main switch in the ‘0’ position to interrupt any leveller movements. Before loading, set the main switch in the ‘1’ position and wait 5 seconds to allow an internal trial run to be performed. Press the ‘LIFT’ button on the control system housing and hold it until the dock leveller is set in the required position. Release...

Open the catalog to page 9

Dock leveller with hinge lip PS Hint! If the ‘LIFT’ pressure is released too early (the leveller is still below the warehouse ramp level), the leveller will not move to its rest position but to its lowest position instead. Set the main switch in the ‘0’ position. Warning! The vehicle can move away from the dock leveller only when the leveller is in its rest position and has been de-energized. The vehicle can move away from the warehouse ramp now. 4. General guidelines on safe operation The dock leveller load capacity specified on the rating plate should not be exceeded. The dock...

Open the catalog to page 10

Dock leveller with hinge lip PS Warning! In case of any danger, set the yellow and red main switch in the ‘0’ position to interrupt movement of the dock leveller. Any leveller movement is immediately interrupted, if: the leveller is switched off with the main switch, the leveller is de-energized in any other way. If the dock leveller is restarted after a power stoppage, press and release the ‘LIFT’ button. The dock leveller is automatically reset to the smooth adjustment control operating mode. Caution! Unassisted operation of the dock leveller can be performed by qualified personnel...

Open the catalog to page 11

Dock leveller with hinge lip PS According to the guidelines of EN 1398, the basic version of the dock leveller was designed for works with forklift trucks with pneumatic or super elastic wheels with tread resembling two 150 mm x 100 mm rectangles. For devices with hard wheels (e.g. electric pallet trucks), please consult a representative of PROMStahl to select the best solution for your docking station. ^ Docking devices allowed to be moved on the dock leveller. PROM dock levellers with nominal load capacity of 60kN are equipped with a platform made of tread plate with thickness of 6 mm...

Open the catalog to page 12All Promstahl WorldWide catalogs and technical brochures

-

Imagefolder

8 Pages

-

LED Dock Lights

1 Pages

-

Safety Dock IN lights system

1 Pages

-

Distribution Book of PromSTAHL

852 Pages

-

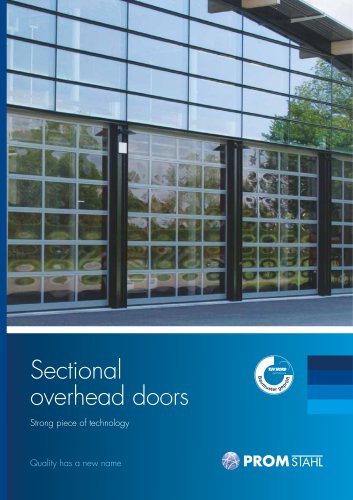

Sectional overhead doors

56 Pages

-

CATALOG

36 Pages