Website:

Promotech

Website:

Promotech

Catalog excerpts

RAIL BULL TRACK WELDING CARRIAGE WITH OSCILLATOR The Rail Bull is a track welding carriage designed to produce butt and fillet welds with or without oscillation. The carriage can work in PA (flat), PB (horizontal vertical), PC (horizontal), PD (overhead horizontalvertical), PE (overhead), PF (vertical-up) and PG (vertical-down) welding positions. • Trailer manufacturing • Truck tanks • Oil tanks • Water storage tanks • Pressure vessels • Vessel overlay/Hard facing • Bridge girders • Structural steel • Structural towers • Panel welding • Transformers • Shipyards • Any application demanding long, continuous welds Rail Bull moves along either rigid or semi-flexible track on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and tracks fixed to flat or curved surfaces by means of various magnetic or vacuum units. The minimum curvature radius required for semi-flexibl

Open the catalog to page 1

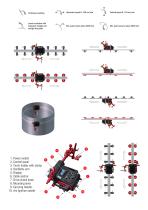

Continuous welding *~*=\* HorizontalsPeed°-120cm/min , Vertical speed 0-110 cm/min Linear oscillation with straight line paths Min. path convex radius 5000 mm Min. path concave radius 5000 mm 3. Torch holder with clamp 7. Drive clutch knob

Open the catalog to page 2

Primary features and benefits: • Compact, lightweight design with durable aluminum cast housing • Convenient power supply 115–230V 50/60Hz • Quick clamping torch holder mechanism for different types of MIG/MAG torches with diameters of 16–22 mm (0.63–0.87”); up to 35 mm (1.38”) option • Precise torch adjustment with screw drive cross slide • Ready to work in both vertical and horizontal positions • Multifunctional LED display (process parameters & warnings) • Consistent heat input reduces distortion • Reduce wasted filler metal - eliminates over welding • Automatic arc on/off initiates...

Open the catalog to page 3

TECHNICAL SPECIFICATIONS RAIL BULL Voltage Welding position (according to EN ISO 6947 and AWS/ASME) Torch diameter Minimum radius of curved workpiece surface Minimum workpiece thickness Horizontal pulling force Vertical pulling force Cross slide adjustment range Horizontal speed Vertical speed Welding settings storage Oscillation type Oscillation (weaving) pattern trapezoid, triangle, straight line Oscillation width Oscillation speed Oscillation delay time Weld paths: I. Trapezoid The carriage travels continuously even during dwell mode. Weld path is determined by weave speed and dwell time...

Open the catalog to page 4

Standard accessories: KBL-0466-17-00-00-0 UCW-0476-20-00-00-0 Torch Holder Dual Arc Ignition Cable of 6.5 m (21 ft) Short Rod Clamp Assembly RIGID TRACK Bracket for magnetic unit DYS-0482-21-00-00-0 Magnetic pivoting unit ZSP-0475-85-00-00-0 Magnetic spacing-adjustable unit ZSP-0523-19-00-00-0 Magnetic narrow unit PDS-0582-10-00-00-0 SEMI-FLEXIBLE TRACK Vacuum modular unit MST-0541-10-02-00-0 Minimum 5 m (16 ft) curvature radius required length 2 m (6.5 ft) Bracket for vacuum modular unit DYS-0541-11-01-00-0 Bracket for magnetic units DYS-0482-19-00-00-0 Bracket for magnetic units...

Open the catalog to page 5

Optional accessories for variety of applications: Rail Bull is suitable for work in both horizontal and vertical positions The Rail Bull welding carriage is supplied in a metal box including: • welding carriage • metal box • cross slide assembly • short rod torch holder with clamp • cable anchor • power cord 3 m (10 ft) • arc ignition cable of 6.5 m (21 ft) • 3 mm hex wrench • 4 mm hex wrench • operator’s manual Rail Bull features User-friendly control panel More information available at www.promotech.eu PROMOTECH Sp. z o.o. ul. Elewatorska 23/1, 15-620 BIAŁYSTOK, POLAND tel. (+48 85) 678...

Open the catalog to page 6All Promotech catalogs and technical brochures

-

PRO-132T

6 Pages

-

PRO-112T

6 Pages

-

PRO-52T

4 Pages

-

PRO-60/110 HP

4 Pages

-

PRODUCTS AT A GLANCE

6 Pages

-

PRO-36 | Compact Mag Drill

2 Pages

-

Drilling & Punching Machines

2 Pages

-

DMP pipe attachments

1 Pages

-

Arbors and cooling system

1 Pages

-

Column & Booms

4 Pages

-

Vertical Robot Positioner

1 Pages

-

PRO-36 Compact Mag Drill

2 Pages

-

PRO-40 Practical Mag Drill

2 Pages

-

PRO-51 Universal Mag Drill

2 Pages

-

PRO-76 Industrial Mag Drill

2 Pages

-

PRO-45 A Pneumatic Mag Drill

1 Pages

-

PRO-111 Heavy Duty Mag Drill

2 Pages

-

PRO 36RH_Petrol_Rail_Drill

2 Pages

-

PRO_36R_Electric_Rail_Drill

2 Pages

-

PRO-200A ATEX

4 Pages

-

Gantry Welding System

2 Pages

-

Magnetic chucks (series 100)

2 Pages

-

PRO - ILBS 150

2 Pages