Catalog excerpts

Solutions for technical screens and sieves Sieves and screen decks specialized producer More than 20 years of wedge wire screen Constant quality guarantee

Open the catalog to page 1

Progress Profile Wire Screens Offer of Progress Industry Group Progress welded profile wire screens can be incorporated in the following processes: separation, filtration, dewatering, drainage, segregation and refining. They are manufactured according to the newest welding technology and meet the most strict quality requirements. The production technology comprises of welding a special profiled working wire to a system of structural wires at each crossing. As a result of this process we receive an exceptionally strong screen which is able to withstand heavy loads. This advanced technology...

Open the catalog to page 2

Production of fuel and lubricants Catalytic Reactors Protection of fittings and compressors Processing of paint and coating Coal enrichment Food products Fluidized beds Municipal drinking water treatment Waste water treatment Industrial water treatment Handling of energy and resources

Open the catalog to page 3

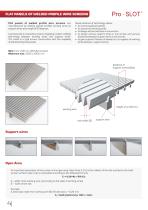

FLAT PANELS OF WELDED PROFILE WIRE SCREENS Flat panels of welded profile wire screens are manufactured by welding special profiled working wires to support wires at an angle of 90 degrees. A precise slot is received by means of applying modern welding technology between working wires and support wires. The result is a rigid screen construction with the capability of withstanding heavy loads. Novel solutions of technology allows: • to control quality of welding • to use various working wires • to design various slot sizes in one screen • to design various support wires in one screen and...

Open the catalog to page 4

CYLINDRICAL SCREENS Cylindrical screens are received by simultaneously winding a spiral of profiled working wire and welding them to support wires, which are arranged along the axis of the cylindrical construction. This technology allows to provide welded profile wire screens for applications where high precision of the screen together with high strength is required. Thanks to the newest welding technology • optional distance between support wires • very precise and repeatable slot • screens in accordance to special requests of our clients Slot: from D,D2 mm (20 Micrometer] OZ -...

Open the catalog to page 5

PRODUCTS ON THE BASIS OF THE WELDED SLOTTED SCREENS Flat sieves Flat sieves are flat panels of welded profile wire, fixed to a frame and adapted to assembly. Depending on the kind of work, flat sieves can be divided into: • Sieves working in dynamic systems - panels to be incorporated in vibrating sieves - special reinforcement depending on the sieve load - special finishing to guarantee secure, long working time and proper fixing of the sieve to the application frame • Sieves working in static systems - do not require any special reinforcements, - can work as bottoms and decks in tanks and...

Open the catalog to page 6

TECHNICAL PARAMETERS Standard working wires Standard working wires prevent sieve clogging because the goods only contact the working wire in two extreme Special working wires Special working wires separate highly abrasive material. During their service the slot width does not increase considerably along with the abrasion of working surface. They are ideal for cylinder and conical sieves used in vibrating centrifuges. They increase the sieve's life span together with preventing clogging. Other dimensions available on a special request Other dimensions available on a special request Support...

Open the catalog to page 7

Complete production programme of technical meshes Slotted wadge wire screens 3 Mesh: from 0,05 mm (50 micrometer] 3 Material: stainless steel, carbon steel 3 Wire: standard wire Sb type, special wire Sbb type 3 Type: simple weave [plain] and oblique wave screens Piano wire screens 3 Polyurethane and rubber lacings 3 Sheets with catches for langitudianal tension Wedge wire tubes cylinders 3 Mesh: from 0,02 mm [20 micrometer] 3 Material: stainless steel, carbon steel 3 Internal and external flow Tytan pessure welded screens 3 0 wire: 4,0-22,0 mm [simple, pressed, Langht - according to...

Open the catalog to page 8All Progress Eco catalogs and technical brochures

-

Energetic resources PROGRESS

8 Pages

-

Harp & Piano screens

4 Pages

-

Fine wire mesh

8 Pages

-

Screen frames

2 Pages

-

Polyurethane screens

12 Pages

-

Slotted wedge wire screens

8 Pages

-

mineral_resources_progress

8 Pages