Catalog excerpts

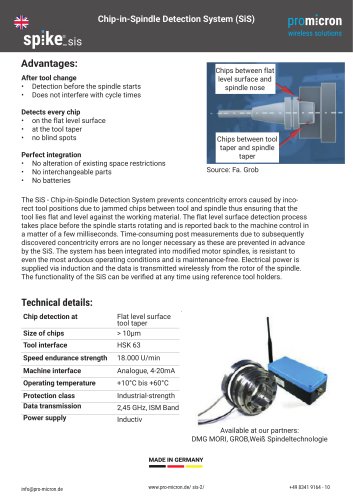

Chip-in-Spindle Detection System (SiS) Chips between flat level surface and spindle nose After tool change • Detection before the spindle starts • Does not interfere with cycle times Detects every chip • on the flat level surface • at the tool taper • no blind spots Chips between tool taper and spindle taper Perfect integration • No alteration of existing space restrictions • No interchangeable parts • No batteries The SiS - Chip-in-Spindle Detection System prevents concentricity errors caused by incorect tool positions due to jammed chips between tool and spindle thus ensuring that the tool lies flat and level against the working material. The flat level surface detection process takes place before the spindle starts rotating and is reported back to the machine control in a matter of a few milliseconds. Time-consuming post measurements due to subsequently discovered concentricity errors are no longer necessary as these are prevented in advance by the SiS. The system has been integrated into modified motor spindles, is resistant to even the most arduous operating conditions and is maintenance-free. Electrical power is supplied via induction and the data is transmitted wirelessly from the rotor of the spindle. The functionality of the SiS can be verified at any time using reference tool holders. Technical details: Chip detection at Size of chips Flat level surface tool taper > 10µm Tool interface Speed endurance strength Machine interface Operating temperature Protection class Data transmission Power supply 2,45 GHz, ISM Band Available at our partners: DMG MORI, GROB,Weiß Spindeltechnologie

Open the catalog to page 1All Pro-micron GmbH & Co. KG catalogs and technical brochures

-

tip_300

2 Pages

-

spike®_easyinline

2 Pages

-

spike®_expertline

2 Pages

-

spike®_assistline

2 Pages