Catalog excerpts

Loading the Label Stock 4 Label Path Diagram 16

Open the catalog to page 1

Notices: The information in this document is subject to change without notice. NO WARRANTY OF ANY KIND IS MADE WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. No liability is assumed for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material. This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated...

Open the catalog to page 2

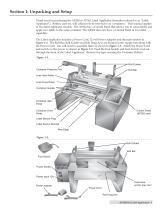

Section 1: Unpacking and Setup Thank you for purchasing the AP360 or AP362 Label Applicator (hereafter referred to as "Label Applicator"). Bottles, cans etc. will collectively be referred to as "containers." This manual applies to two label applicator models. The AP362 has a Control Panel that allows you to count labels and apply two labels to the same container. The AP360 does not have a Control Panel or two-label capability. The Label Applicator includes a Power Cord, 12 volt Power Adapter and the parts shown in Figure 1-1. The Roll Bar, Roll Guides and Roll Drag Arm are located in the...

Open the catalog to page 3

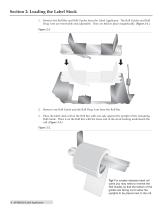

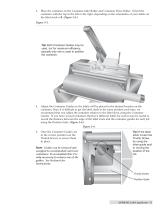

Section 2: Loading the Label Stock 1. Remove the Roll Bar and Roll Guides from the Label Applicator. The Roll Guides and Roll Drag Arm are removable and adjustable. They are held in place magnetically. (Figure 2-1.) Remove one Roll Guide and the Roll Drag Arm from the Roll Bar. Place the label stock roll on the Roll Bar with one side against the upright of the remaining Roll Guide. Place it on the Roll Bar with the loose end of the stock feeding underneath the roll. (Figure 2-2.) Tip! For smaller diameter label roll cores you may need to reverse the Roll Guides so that the bottom of the...

Open the catalog to page 4

Place the Roll Drag Arm under the Roll Bar. The Roll Drag Arm may be placed on either side of the Roll Bar but the rounded tip of the Roll Drag Arm should be located in the center of the inside of the core. The arm is spring loaded so that there is downward pressure on the inside of the roll. This helps prevent application alignment problems near the end of a roll. (Figure 2-3.) Place the removed Roll Guide back on the Roll Bar and slide it close to, but not touching the label stock roll. (Figure 2-4.) Tip! Roll Guide Uprights must not pinch the label stock roll. (The label stock roll must...

Open the catalog to page 5

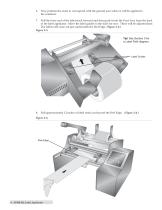

Now position the stock to correspond with the general area where it will be applied to the container. Pull the loose end of the label stock forward and then push it into the Feed Area from the back of the label applicator. Move the label guides to the sides for now. These will be adjusted later. The labels will come out just underneath the Peel Edge. (Figure 2-6.) Figure 2-5. Tip! See Section 5 for a Label Path diagram. Label Guides Pull approximately 12 inches of label stock out beyond the Peel Edge. (Figure 2-6.) Peel Edge

Open the catalog to page 6

Take the loose label stock and feed it between the Liner Idler Roller and the Liner Drive Roller. (Figure 2-7.) In order to feed the label stock between the rollers, the Liner Idler Roller should be in the unclamped position. For some thicker label stock, it may be necessary to remove the labels from the liner before performing this step. (See Figure 2-10 for a detailed diagram of the Liner Idler Roller positions.) Note: This procedure assumes that the first 12 inches of labels will not be applied to the container using the Label Applicator. Of course, you may still apply these labels by...

Open the catalog to page 7

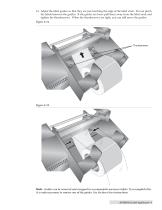

11. If necessary, adjust the position of the liner on the Peel Edge left/right to align the liner with the label stock roll. Also, adjust the Label Sensor using the Label Sensor Bracket so that the Label Sensor Flag is roughly centered on the label stock. (Figure 2-9.) Figure 2-9. 12. Push the Liner Idler Roller into the clamped position. (Figure 2-10.) Figure 2-10. Clamped Position Unclamped Position 13. The labels are now ready for application. Note: Position the Label Applicator on the edge of a table so that the liner falls to the floor. This will prevent excess labels from interfering...

Open the catalog to page 8

14. Adjust the label guides so that they are just touching the edge of the label stock. Do not pinch the labels between the guides. If the guides are loose pull them away from the label stock and tighten the thumbscrews. When the thumbscrews are tight, you can still move the guides. Figure 2-11. Note: Guides can be removed and swapped to accommodate narrower labels. To accomplish this it is only necessary to remove one of the guides. See Section 6 for instructions.

Open the catalog to page 9

Section 3: Loading the Container The AP360/362 can apply labels to a variety of containers including wine bottles, soda bottles, jars, cans, etc. Depending on the container type that you are labeling, you have several different options. You may use the Container Pressure Arm to hold the containers against the rollers, but that may not be necessary. You may use one or both of the Container Guides. Use these steps as a guide for applying labels. Ultimately, you will find the method that is fastest for you, which may or may not include use of the Container Pressure Arm and/or one or both...

Open the catalog to page 10

3. Place the container on the Container Idler Roller and Container Drive Roller. Orient the container with the top to the left or the right, depending on the orientation of your labels on the label stock roll. (Figure 3-3.) Tip! Both Container Guides may be used, but for maximum efficiency, typically only one is used to position the container. 4. Adjust the Container Guides so the labels will be placed in the desired location on the container. Since it is difficult to get the label stock in the same position each time, we recommend that you adjust the container relative to the label stock...

Open the catalog to page 11

Important Note: For bottles with a neck such soda, beer or wine bottles only one Container Guide can be used. Move the unused Container Guide to the far right or left side of the labeling area. For cans or other containers that do not have a tapered neck, both Container Guides can be used, if desired. 6. With the container in place, move the Container Pressure Arm right or left until it is roughly centered on the container. Push down on the arm until the roller on the end of the arm touches the container. Remove the container. Push down the arm approximately 1/2 inch more. Attempt to place...

Open the catalog to page 12All Primera Technology catalogs and technical brochures

-

Impression IP60

2 Pages

-

EddieBrochure

4 Pages

-

Bravo 4200 Series

56 Pages

-

Bravo SE-3

56 Pages

-

RW-7

16 Pages

-

AP550

32 Pages

-

LX1000/LX2000

90 Pages

-

LX500/LX500c

52 Pages

-

Bravo series

1 Pages

-

CX1000

4 Pages

-

LP130 Laser Marking System

2 Pages

-

RX900F

2 Pages

-

RX900

2 Pages

-

CX-FX series

8 Pages

Archived catalogs

-

LX series

1 Pages

-

LX series_2013

8 Pages