Catalog excerpts

The Bend The Combi The Laser The Punch The System The Software Shear Genius Integrated punching and shearing ®

Open the catalog to page 1

The vast majority of all fabricated sheet metal components are rectangular, so a highly economical method to produce them is to perform first punching and then shear the components loose in the same automatic process with an integrated right angle shear. Also, parts with two or three straight edges are perfect for fabrication with a right angle shear. Shear Genius® provides more capacity, quality and costefficiency for flexible sheet metal working than any comparable system. Twenty years of experience in right angle shear technology combined with proven field performance in nearly 2,000...

Open the catalog to page 2

Servo-electric Shear Genius SGe ® Highest productivity with integrated shearing Competitive edge for today's demanding business environment Prima Power's basic Shear Genius® package consists of * Automatic loading equipment * 300 kN (33US ton) servo-electric turret punch press with capacity up to nearly 400 tools * Integrated right angle shear There are two Shear Genius® models for standard size sheets (max.) * SGe6: 3,074 mm x 1,565 mm (120" x 60" ) * SGe8: 4,300 mm x 1,565 mm (170" x 60" )

Open the catalog to page 3

Expertise in integrated right angle shear technology

Open the catalog to page 4

THE SHEAR GENIUS® PHILOSOPHY The Shear Genius® philosophy is to provide one machine capable of transforming a full sized sheet into finished parts with scrap separated.These parts can be moved to final production stages without the need for secondary operations for costly material handling between loading, punching, shearing, sorting and unloading. With Shear Genius® you can use pre-cut sheets, but normally standard size sheets are processed while major savings are achieved through efficient nesting. It is important not to think that this is the only way that Shear Genius® can be operated....

Open the catalog to page 5

SERVO-ELECTRIC HIGH-PERFORMANCE PUNCHING An early and major step towards sustainable fabrication was taken on the introduction of the servo-electric E series turret punch press in 1998. Now Prima uses already the third generation of this technology. The inherent benefits of servo-electric include energy efficiency, versatility and accuracy and low maintenance cost. This amounts to superior fabrication capabilities as well as outstanding operation economy, i.e. truly remarkable savings. Performance values are truly impressive: * Hit speed up to 1,000 hpm * Sheet positioning speed up to 150...

Open the catalog to page 6

FastAuto Index Large tooling capacity A large number of index tools facilitates set-ups and programming, shortens tool change times and increases production speed. Maximum index rotating speed is 250 rpm.The rotation mechanism of the punch and die is mechanically engaged and disengaged vertically. It enables full tonnage and punch speeds to be used in any station, with any tool size. A totally re-designed turret can be chose; it can be customized and optimized for any requirement. Simultaneously, a record-breaking number of 384 tools can be available in the turret; thus unnecessary set-ups...

Open the catalog to page 7

SOPHISTICATED SOFTWARE Special attention has been paid to ease of machine setups and efficient programming. The benefits include excellent possibilities for e.g. roll forming and for other special tooling. With optional features, the software can be made compatible with standard ERP connections for importing orders and exporting reports. NC Express™ CNC programming system is a user friendly, integrated, and automated tool for programming the equipment. NC Express™ is for single part drafting and tooling or a fully-automated programming system for large production line. Tulus® is management...

Open the catalog to page 8

WIDE RANGE OF OPTIONS There is a wide selection of optional equipment and features with which the standard machine can be customized to meet specific requirements. Most of these can also be installed later as machine upgrades. Upforming An additional forming cylinder is available.It is a servo operated ram installed in the lower machine frame. It lifts the forming die to a programmed position.The tool is retracted after forming, preventing a collision with the moving sheet. With this cylinder, versatile forms up to 16 mm (0.63") in height (incl. sheet thickness) can be made. Fast component...

Open the catalog to page 9

THE INTELLIGENT RIGHTANGLE SHEAR The Prima Power right angle shear is extremely fast in operation. Programmable blade height and automatic stroke depth adjustment combine to allow shearing speed up to 110 m/min (72.16"/s). In the right angle shear, sheet holders are programmable, allowing shearing close to forms. Blade speed is automatically selected for the maximum speed.Together with automatic shearing modes this optimizes operation speed. The intelligent right angle shear always allows using the optimum solution for the stroke according to the part size to be made in each case, e.g. - a...

Open the catalog to page 10

FLEXIBLE MATERIAL HANDLING SOLUTIONS The Shear Genius® construction is compatible with the whole Prima Power range of optional modular material handling equipment for sorting and stacking. Thus Shear Genius® solutions can automate - material storage with automatic feed loading with possibility of material change during machine operation component exit scrap removal (punching and shearing) sorting and stacking of components Shear Genius® technology is optimal for integration with subsequent bending by an automatic Prima Power bending cell. Prima Power PSBB processes blank sheets into bent...

Open the catalog to page 11

404GB/May2014 © Prima Industrie Group / Subject to changes without prior notice

Open the catalog to page 12All PRIMA POWER catalogs and technical brochures

-

Prima Power LPBB

16 Pages

-

Punch Genius

8 Pages

-

The Press | eP-Press

16 Pages

-

The Laser | 3D line

36 Pages

-

The Laser | 2D line

36 Pages

-

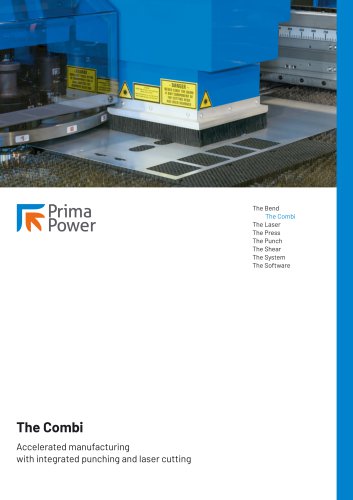

The Combi

24 Pages

-

Prima Power EBe

2 Pages

-

Texas-style

4 Pages

-

Tulus® Cell

4 Pages

-

Prima Power Software

4 Pages

-

P series

24 Pages

-

eP-1030

8 Pages

-

eP1

2 Pages

-

Shear Genius® SGe 5

4 Pages

-

Shear Brilliance SBe

8 Pages

-

LPe6x

8 Pages

-

LPef Series

8 Pages

-

Platino Fiber

12 Pages

-

Laser Genius

2 Pages

-

Platino

6 Pages

-

ZAPHIRO

6 Pages

-

MAXIMO

2 Pages

-

DOMINO

2 Pages

-

Laser Next

8 Pages

-

RAPIDO

12 Pages

-

LASERDYNE 430

4 Pages

-

Laserdyne 795

8 Pages

-

OPTIMO

6 Pages

-

E5x

4 Pages

-

SYNCRONO

7 Pages

-

LPe6f

4 Pages

-

X SERIES PRESS BRAKE

8 Pages

-

BCe

2 Pages

-

FastBend - FBe

8 Pages

-

LPe - Laser Punching

20 Pages

-

EB

2 Pages

-

EBe

12 Pages

-

eP Brake

8 Pages

-

Optimo Vivida

2 Pages

-

C5 Punch Press

16 Pages

-

E-series

20 Pages

-

E6x Punch Press

4 Pages

Archived catalogs

-

OPTIMO BROCHURE

3 Pages

-

RAPIDO BROCHURE

6 Pages

-

MOSAICO BROCHURE

3 Pages

-

DOMINO BROCHURE

2 Pages

-

SYNCRONO BROCHURE

7 Pages

-

PLATINO BROCHURE

6 Pages

-

MAXIMO BROCHURE

3 Pages