Catalog excerpts

PUNCHING LASER CUTTING BENDING INTEGRATED PUNCHING & SHEARING INTEGRATED PUNCHING & LASER CUTTING FLEXIBLE MANUFACTURING SYSTEMS ® ® E SERIES TURRET PUNCH PRESSES

Open the catalog to page 1

The new generation of FINN-POWER's servo operated E seríes turret punch presses offers versatile punching, nibbling, forming and bending capacity on a single machine Based on the ECOPUNCH® concept, the E series is an astonishing money saver, featuring Moreover, carefully planned ergonomics, low noise level and modern industrial design combine to make the E series turret punch press a truly state- of-the-art solution for flexible, productive fabrica-

Open the catalog to page 2

FINN-POWER E TECHNOLOGY OFFERS YOU Average power consumption: 5 kVA / 4 kW Power consumption when idle: less than 1 kW Power supply connection: 15 kVA [3 x 20 A fuse / 400 V)

Open the catalog to page 3

DIFFERENT SHEET SIZES FINN-POWER E5 - small layout and convenient operation Max sheet size without repositioning 2,530 mm x 1,270 mm [96 " x 48 "] Punching speed 800 hpm at 1 mm pitch FINN-POWER E6 - higher range of automation and optional features Max sheet size without repositioning 3,074 mm x 1,542 mm (121 " x 60 ") Punching speed 900 hpm at 1 mm pitch FINN-POWER E8-full support for large sheet sizes Punching speed 900 hpm at 1 mm pitch Servo operated: the punching and forming stroke become NC controlled axes Extremely high punching and forming accuracy Robust "□" type frame for perfect...

Open the catalog to page 4

FINN-POWER's ECOPUNCH® concept is an aston- ishing money saver in terms of energy consump- tion. It uses braking energy in the acceleration of Operation/Idle Mode/Stand-by Mode □nee the machine has completed a task it switches to IDLE MODE. In this mode power consumption is only 1/4 of the active mode. If the machine is off-duty for 10 minutes it switches to the energy saving STAND BY mode, being ready for operation (ACTIVE MODE) without delay at a single push of a Energy from line supply with recovery Energy / 1 Energy from recovered for . | line supply further use ' without recovery The E...

Open the catalog to page 5

OPERATING PRINCIPLE In the punching mode, a servo operated wedge (1 ] moves over the roll connected to the ram (2) caus- ing it and, consequently, the tool (3) to move down- wards. After the ram has reached its programmed lower position, it returns back to its programmed upper position, actuated by pneumatic pressure. In the forming mode, ram movement is pro- grammed to stop when the desired forming stroke position has been reached, after which the return movement of the roll and the ram begins. The stroke is NC-controlled and thus forming accuracy is outstanding. The static counter-force...

Open the catalog to page 6

PUNCHING FEATURES Solid engineering FINN-POWER machines have a rugged "□" frame. Upper and lower turret plates are machined as a set to eliminate any flexing and yawing. Sheet positioning The machine features an axis actuation system based on maintenance free AC-servo motors. The rotation movement of the motors is transformed into linear movement by precision ball screws or rack & pinion systems (EB). The construction allows high positioning speeds and axis accelera- tion with excellent accuracy. Machine dependent default sheet size can be processed without repo- sitioning (E5/EB). The...

Open the catalog to page 8

Fast Auto index system Easy load features Up to 10 large index stations (SB.9 mm / 3.5") and even 80 indexable tools with R Multi-Tools® The fast auto-index system is based on an AC servo motor; the rotation mechanism of the punch and die is mechanically engaged and disengaged verti- cally. Tool rotation can be programmed in 0.001° increments and throughout the 360° rotation. The system automatically selects the shorter path to desired angle. Full tonnage and punch speeds can be used in any station, with any tool size. Powerful numerical control E Series turret punch presses are equipped...

Open the catalog to page 9

PRODUCTION NEEDS VARY - MODULAR OPTIONS One of the cornerstones of FINN-POWER's well- known flexibility and versatility is the wide range of optional equipment available for meeting specific fabrication requirements. Each machine can be customized to meet specific requirements exactly, using standard modules. Extra clamp The machine can be equipped with an optional sheet clamp for better grip and additional support for larger sheet sizes. lubrication systems Continuous automatic tool lubrication extends the life- time of spring housing, slid- punch, and makes stripping The sheet lubricator...

Open the catalog to page 10

Continuous forming Wilson Wheel and Mate Roller Ball are special tools for continuous forms. FINN-POWER has developed these applications further. The tools can be used in index and upforming stations, and spe- cial soft commands can be used. This allows forms which a varying height over their length. Flexible tapping solutions Versatile tapping capability can be integrated either with a servo driven, six-station tapping unit Fast component identification FINN-POWER offers several solutions for adding information to components to ensure reliable iden- tification in the next process stage...

Open the catalog to page 11

Quick Change Die Holder, QCHD Current punching technology allows the availabil- ity of truly versatile capacity in a single turret setup. Yet, in flexible fabrication and fast short- batch manufacturing situations, the need for tool set-up change always arises. Tool change is in itself an operation which takes its own time and may lead to even costly mistakes. As opposed to traditional dies, a new quick change die is removed by just opening the clamp and drawing the die out. No tools are required. Similarly, a new die is simply pushed in and the clamp closed - a matter of seconds. Further...

Open the catalog to page 12

Tulus software includes a wide range of advanced features depending on package An essential element of FINN-POWER versatility in punching is sophisticated software. FINN-POWER has developed its own user interface and program- ming system for production management. Com- ponent programs are made fast and the function- alities of the integrated solution make production flow flexible and simple to manage. Tulus® is FINN-POWER's new, integrated and scal- able software tool for integrated and centralized management of fabrication from a single machine to factory wide fabrication process. Tulus®...

Open the catalog to page 13All PRIMA POWER catalogs and technical brochures

-

Prima Power LPBB

16 Pages

-

Punch Genius

8 Pages

-

The Press | eP-Press

16 Pages

-

The Laser | 3D line

36 Pages

-

The Laser | 2D line

36 Pages

-

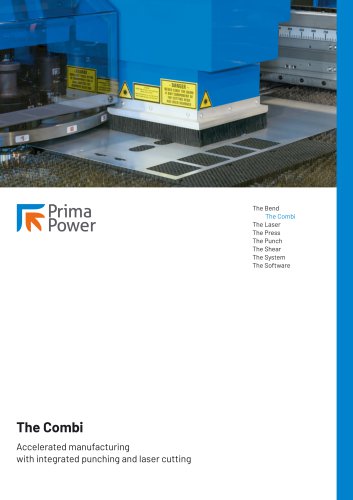

The Combi

24 Pages

-

Prima Power EBe

2 Pages

-

Texas-style

4 Pages

-

Tulus® Cell

4 Pages

-

Prima Power Software

4 Pages

-

P series

24 Pages

-

eP-1030

8 Pages

-

eP1

2 Pages

-

Shear Genius® SGe 5

4 Pages

-

Shear Genius® SGe 6 / SGe 8

12 Pages

-

Shear Brilliance SBe

8 Pages

-

LPe6x

8 Pages

-

LPef Series

8 Pages

-

Platino Fiber

12 Pages

-

Laser Genius

2 Pages

-

Platino

6 Pages

-

ZAPHIRO

6 Pages

-

MAXIMO

2 Pages

-

DOMINO

2 Pages

-

Laser Next

8 Pages

-

RAPIDO

12 Pages

-

LASERDYNE 430

4 Pages

-

Laserdyne 795

8 Pages

-

OPTIMO

6 Pages

-

E5x

4 Pages

-

SYNCRONO

7 Pages

-

LPe6f

4 Pages

-

X SERIES PRESS BRAKE

8 Pages

-

BCe

2 Pages

-

FastBend - FBe

8 Pages

-

LPe - Laser Punching

20 Pages

-

EB

2 Pages

-

EBe

12 Pages

-

eP Brake

8 Pages

-

Optimo Vivida

2 Pages

-

C5 Punch Press

16 Pages

-

E6x Punch Press

4 Pages

Archived catalogs

-

OPTIMO BROCHURE

3 Pages

-

RAPIDO BROCHURE

6 Pages

-

MOSAICO BROCHURE

3 Pages

-

DOMINO BROCHURE

2 Pages

-

SYNCRONO BROCHURE

7 Pages

-

PLATINO BROCHURE

6 Pages

-

MAXIMO BROCHURE

3 Pages