Website:

PRECITEC OPTRONIK

Website:

PRECITEC OPTRONIK

Group: PRECITEC

Catalog excerpts

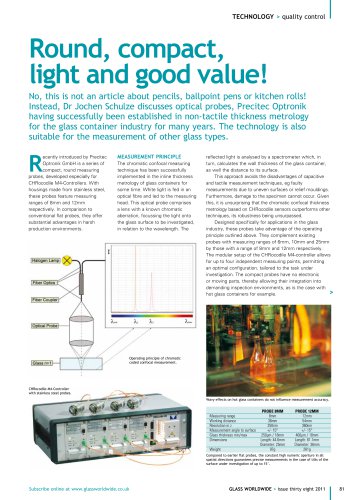

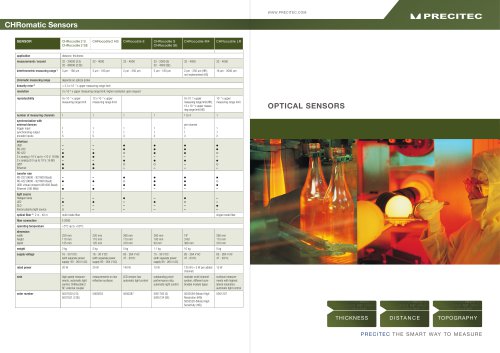

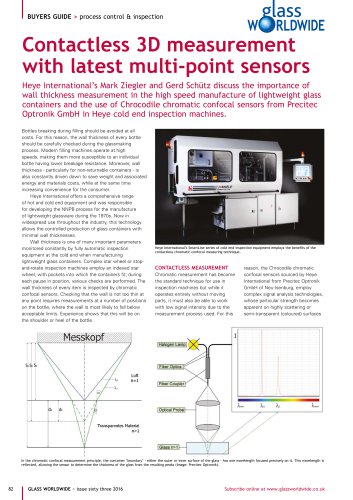

technology > quality control Round, compact, light and good value! No, this is not an article about pencils, ballpoint pens or kitchen rolls! Instead, Dr Jochen Schulze discusses optical probes, Precitec Optronik having successfully been established in non-tactile thickness metrology for the glass container industry for many years. The technology is also suitable for the measurement of other glass types. ecently introduced by Precitec Optronik GmbH is a series of compact, round measuring probes, developed especially for CHRocodile M4-Controllers. With housings made from stainless steel, these probes feature measuring ranges of 8mm and 12mm respectively. In comparison to conventional flat probes, they offer substantial advantages in harsh production environments. MEASUREMENT PRINCIPLE The chromatic confocal measuring technique has been successfully implemented in the inline thickness metrology of glass containers for some time. White light is fed in an optical fibre and led to the measuring head. This optical probe comprises a lens with a known chromatic aberration, focussing the light onto the glass surface to be investigated, in relation to the wavelength. The reflected light is analysed by a spectrometer which, in turn, calculates the wall thickness of the glass container, as well the distance to its surface. This approach avoids the disadvantages of capacitive and tactile measurement techniques, eg faulty measurements due to uneven surfaces or relief mouldings. Furthermore, damage to the specimen cannot occur. Given this, it is unsurprising that the chromatic confocal thickness metrology based on CHRocodile sensors outperforms other techniques, its robustness being unsurpassed. Designed specifically for applications in the glass industry, these probes take advantage of the operating principle outlined above. They complement existing probes with measuring ranges of 6mm, 10mm and 25mm by those with a range of 8mm and 12mm respectively. The modular setup of the CHRocodile M4-controller allows for up to four independent measuring points, permitting an optimal configuration, tailored to the task under investigation. The compact probes have no electronic or moving parts, thereby allowing their integration into demanding inspection environments, as is the case with hot glass containers for example. Operating principle of chromatic coded confocal measurement. CHRocodile M4-Controller with stainless steel probes. Wavy effects on hot glass containers do not influence measurement accuracy. Probe 8mm Measuring range 8mm Working distance 36mm 250nm Resolution in z Measurement angle to surface +/- 15° Glass thickness min/max 250µm / 18mm Dimensions Length: 44.6mm Diameter: 25mm Weight 97g Compared to earlier flat probes, the constant high numeric aperture in all spatial directions guarantees precise measurements in the case of tilts of the surface under investigation of up to 15°. Subscribe online at www.glassworldwide.co.uk Glass Worldwide > issue thirty eight 2011

Open the catalog to page 1

technology > quality control IMPROVED PERFORMANCE Precitec Optronik has co-operated with leading hollow glass manufacturers for many years, constantly searching for product improvements. As a consequence, the performance of the latest probes has been improved, while providing lower prices for the customer. Based on stainless steel, the design guarantees a long lifetime, as well as high measuring accuracy over many production cycles. The probes are very light, meaning that the requirements on the mechanical stability of the complete setup are substantially less demanding than before. The...

Open the catalog to page 2All PRECITEC OPTRONIK catalogs and technical brochures

-

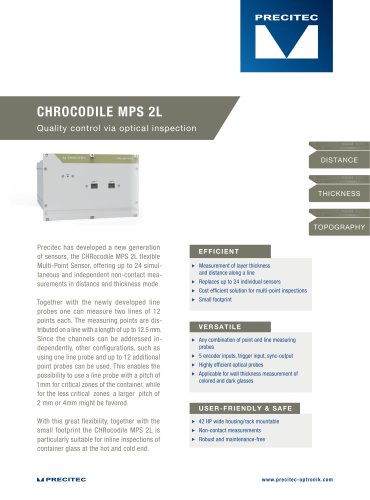

CHRocodile MPS 2 L

2 Pages

-

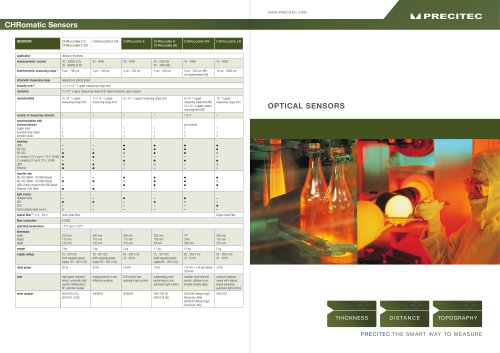

CHRomatic Sensors

2 Pages

-

Heads

2 Pages

-

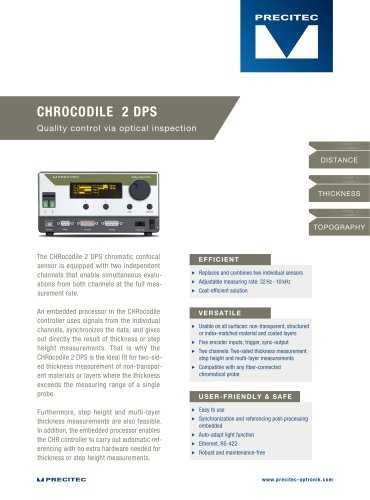

CHRocodile 2 DPS

2 Pages

-

CHRomatic Vision Camera

2 Pages

-

CHRocodile C Extension Box

1 Pages

-

Flying Spot Scanner

2 Pages

-

Measuring Sensors

2 Pages

-

Optical Probes

2 Pages