Inspection machines: 3D-measurement of lightweight glass containers using multipoint sensors

1 /

2Pages

Catalog excerpts

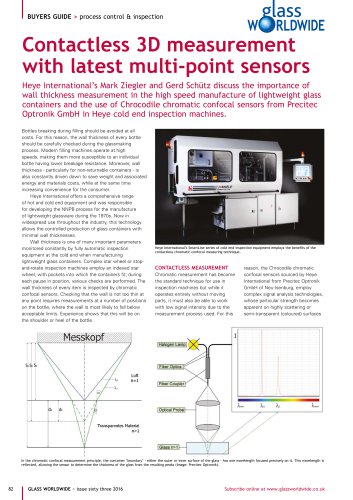

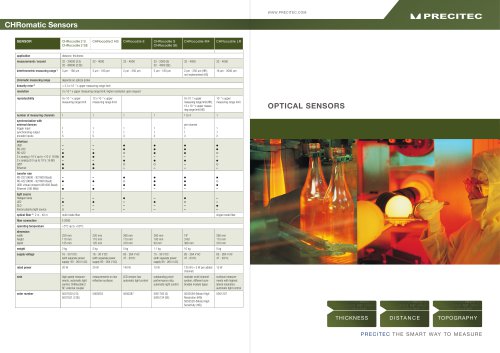

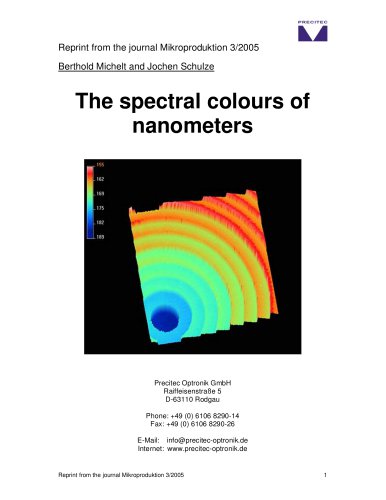

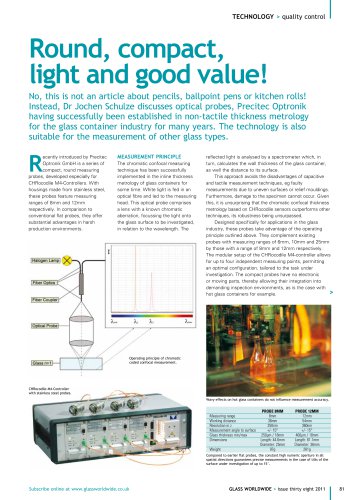

BUYERS GUIDE > process control & inspection Contactless 3D measurement with latest multi-point sensors Heye International’s Mark Ziegler and Gerd Schütz discuss the importance of wall thickness measurement in the high speed manufacture of lightweight glass containers and the use of Chrocodile chromatic confocal sensors from Precitec Optronik GmbH in Heye cold end inspection machines. Bottles breaking during filling should be avoided at all costs. For this reason, the wall thickness of every bottle should be carefully checked during the glassmaking process. Modern filling machines operate at high speeds, making them more susceptible to an individual bottle having lower breakage resistance. Moreover, wall thickness - particularly for non-returnable containers - is also constantly driven down to save weight and associated energy and materials costs, while at the same time increasing convenience for the consumer. Heye International offers a comprehensive range of hot and cold end equipment and was responsible for developing the NNPB process for the manufacture of lightweight glassware during the 1970s. Now in widespread use throughout the industry, this technology allows the controlled production of glass containers with minimal wall thicknesses. Wall thickness is one of many important parameters monitored constantly by fully automatic inspection equipment at the cold end when manufacturing lightweight glass containers. Complex star wheel or stopand-rotate inspection machines employ an indexed star wheel, with pockets into which the containers fit; during each pause in position, various checks are performed. The wall thickness of every item is inspected by chromatic confocal sensors. Checking that the wall is not too thin at any point requires measurements at a number of positions on the bottle, where the wall is most likely to fall below acceptable limits. Experience shows that this will be on the shoulder or heel of the bottle. Heye International’s SmartLine series of cold end inspection equipment employs the benefits of the contactless chromatic confocal measuring technique. CONTACTLESS MEASUREMENT Chromatic measurement has become the standard technique for use in inspection machines but while it operates entirely without moving parts, it must also be able to work with low signal intensity due to the measurement process used. For this reason, the Chrocodile chromatic confocal sensors sourced by Heye International from Precitec Optronik GmbH of Neu-Isenburg, employ complex signal analysis technologies, whose particular strength becomes apparent on highly scattering or semi-transparent (coloured) surfaces In the chromatic confocal measurement principle, the container ‘boundary’ - either the outer or inner surface of the glass - has one wavelength focused precisely on it. This wavelength is reflected, allowing the sensor to determine the thickness of the glass from the resulting peaks (image: Precitec Optronik). GLASS WORLDWIDE > issue sixty three 2016 Subscribe online at www.glassworldwide

Open the catalog to page 1

BUYERS GUIDE > process control & inspection Multi-point measurement system with chromatic confocal sensor for measuring the wall thickness of glass containers. A single-point sensor is shown in the background in the right-hand image (images: Heye International). that defeat other 3D measurement processes. A major advantage of this technology is its suitability for contactless in-line measurement of container glass, the bottles being axially rotated in the star wheel pocket while the glass thickness is captured using compact chromatic measuring heads. So fast is the bottle rotation in this...

Open the catalog to page 2All PRECITEC OPTRONIK catalogs and technical brochures

-

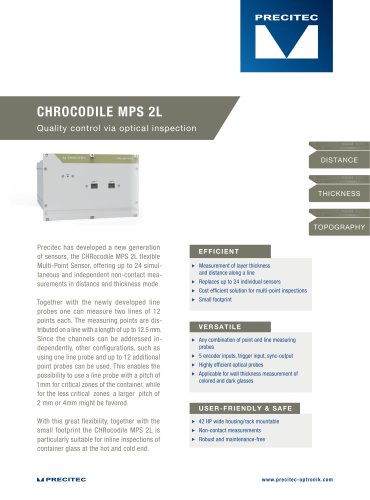

CHRocodile MPS 2 L

2 Pages

-

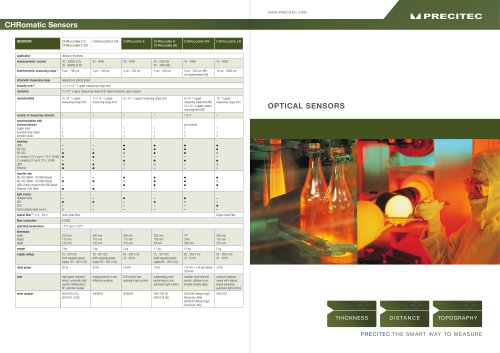

CHRomatic Sensors

2 Pages

-

Heads

2 Pages

-

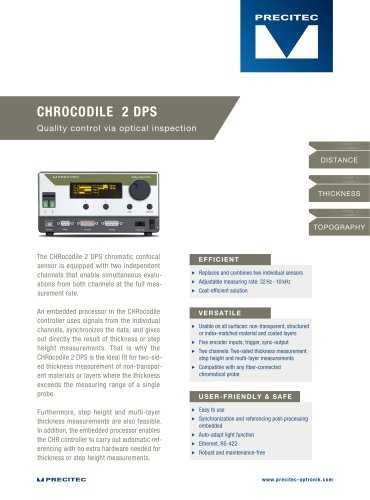

CHRocodile 2 DPS

2 Pages

-

CHRomatic Vision Camera

2 Pages

-

CHRocodile C Extension Box

1 Pages

-

Flying Spot Scanner

2 Pages

-

Measuring Sensors

2 Pages

-

Optical Probes

2 Pages