Catalog excerpts

OUTSIDE OVERVIEW Control NUM Flexium+ and B&R control Automation (optional) by a practical modular construction system: chain loader KL105, KL315 or robot loading system Storage and stowage possibilities integrated storage table and folding compartments for accessories Software NUMROTOplus® Control panel with 21.5" touch screen, ergonomic mouse and RFID interface Connection for cleaning pistol Cast mineral machine stand made of polymer concrete Innovative extraction system with downward-directed airflow

Open the catalog to page 2

INSIDE OVERVIEW Grinding spindle peak power 35 kW up to 12,000 rpm Workpiece gripper from diameter 6 to 32 mm Measuring probe for determining all relevant tool data Second coolant nozzle ring automatic selection depending on the size of the grinding wheel Automation interface chain loader, robot loading system CNC-controlled coolant nozzles coolant nozzle jet follows the grinding point Interface for workpiece holder interface with flat work surface, clamping cartridges with integrated RFID chip A-axis direct drive with 10 kW and infinitely variable rotation speed up to 1,200 rpm Innovative...

Open the catalog to page 3

CNC-CONTROLLED COOLANT NOZZLES EFFICIENT COOLING The coolant nozzles of the ISOG 24 move with the grinding point along the grinding wheel, automatically controlled by software. This creates efficiency: Coolant consumption is reduced by up to 80 percent. The grinding results are better – still the grinding is faster and more productive. The new, intelligent coolant nozzles sit in the shape of a rim directly on the grinding head. Operations become easier The new cooling system from ISOG does not need any set-up time and is very flexible because the cooling is no longer manually set up or...

Open the catalog to page 4

EXTRACTION SYSTEM AIRFLOW FOLLOWS GRAVITY The ISOG 24 is breaking new ground here: For the first time, the airflow is directed downwards – physically convincing, as gravity goes in the same direction. Thanks to the controlled airflow, there is less fogging, which gives the operator a much better view of the grinding process. The supply air flows into the machine through a long opening at the top of the cabin. The airflows are smooth and straight, with low flow velocity. fire protection flap and flow meter for the extraction The airflow and the extraction are continuously monitored in real...

Open the catalog to page 5

A-AXIS POWER MEETS FLEXIBILITY MAXIMUM WORKING SIZES The A-axis is infinitely variable and has been designed for a maximum rotation speed of 1,200 rpm. The electric direct drive has a torque of 63 Nm and a power of 10 kW at 410 rpm. The interface for the clamping systems has been defined with a flat work surface in such a way that a quick and easy change of the clamping systems is possible. new interface for quick and easy change of clamping systems electric direct drive twisted step drill profile tool spade drill twist drill with differential twist infinitely variable rotation speed,...

Open the catalog to page 6

CLAMPING SYSTEMS CHANGE IN A FEW MINUTES Thanks to the adaptive A-axis, the clamping system can be changed within a few minutes. For this purpose, clamping cartridges are used, which are configured as required. Changing the pre-assembled clamping cartridges is fast on any day. hydraulic clamping cartridge diameter 32 mm Integrated chip provides data ISOG integrates an RFID chip into each clamping cartridge. Thus, the respective clamping system can be automatically identified during insertion. With the help of the chip the clamping cycles are continuously recorded, which enables preventive...

Open the catalog to page 7

12-FOLD WHEEL CHANGER LARGE SELECTION, SMALL EXPENDITURE OF TIME Twelve grinding wheel packages with HSK A50 holder are ready for use at any time. Twelve positions are designed for grinding wheels up to a diameter of 125 mm, three of the positions can also be used for grinding wheels up to 210 mm. The machine is thus extremely flexible: Tools and parts can be manufactured and sharpened in just one single clamping. Within 14 seconds, the ISOG 24 changes the grindingwheel packages, whereby, workpiece for workpiece, valuable time can be gained. The ISOG 24 achieves an unusually high...

Open the catalog to page 8

AUTOMATION (OPTIONAL) AUTOMATION AS NEEDED The ISOG 24 is available with different automation solutions, all of which can be adapted to a dedicated interface. There is a choice of chain loaders with 105 and 315 places as well as a robot cell. The chain loaders are flanged to the machine as a module to save space. All automation solutions can also be loaded and unloaded during operation. Accessories required for this can be easily accommodated on the storage table as well as in the integrated folding compartments. These can be individually positioned. The entire equipping of the chain loader...

Open the catalog to page 9

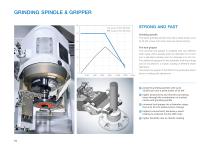

GRINDING SPINDLE & GRIPPER 30 STRONG AND FAST Grinding spindle The direct grinding spindle drive has a peak power of up to 35 kW. Linear and rotary axes are driven directly. The tool gripper The universal tool gripper is available with two different prism sizes: with a carbide prism for diameter 3 to 16 mm and a standard carbide prism for diameter 6 to 32 mm. The additional grippers for the automatic bushing change can be mounted for a chaotic loading of different shank diameters. The entire tool gripper of the ISOG 24 is particularly fast in terms of setting and adjustment. powerful...

Open the catalog to page 10

PRECISION AT THE TOUCH OF A BUTTON The tool probe of the ISOG 24 can be used in many different ways. In conjunction with NUMROTOplus® it allows to record all relevant tool data. Ground values can thus be controlled directly in the machine and be compensated immediately if necessary. Second measuring probe for grinding wheel data The second measuring probe is useful in many respects. In conjunction with dressing and regeneration of grinding wheels, it allows to machine even large batch sizes fully automatically. The basic dimensions of the grinding wheel can be determined. @ precise and fast...

Open the catalog to page 11

CLEAR AND FUNCTIONAL Multifunctional control panel The large, high-resolution 21.5" flat screen is very comfortable for the operator, especially when programming on the machine. The powerful machine computer allows fastest simulations in high resolution quality. All specifications for a screen workstation are met. The control panel includes an ergonomic, space-saving trackball mouse and a half-stop keyboard. So the desk looks very tidy. And it's designed for durability, as all components are oil resistant. The ISOG 24 also offers a service mode. This is secured via a registration via RFID...

Open the catalog to page 12All Precision Surfacing Solutions GmbH & Co. KG catalogs and technical brochures

-

Kehren RP 8

2 Pages

-

Elb-gantryLine

2 Pages

-

aba ecoLine

2 Pages

-

Micron Macro-SK

2 Pages

-

Micron Macro-S

2 Pages

-

aba powerLine

2 Pages

-

Elb-microCut

2 Pages

-

Elb-broachLine BGS

2 Pages

-

REFORM Trirex

2 Pages

-

aba multiLine

2 Pages

-

Elb-broachLine BG

2 Pages

-

Image_Brochure_PSS

11 Pages

-

Lapmaster Model 20

2 Pages

-

Lapmaster Model 15

2 Pages

-

Lapmaster Model 48

2 Pages

-

Lapmaster Model 24

2 Pages

-

Lapmaster DL 370

2 Pages

-

Lapmaster Model 36

2 Pages

-

Kehren NEO 5

2 Pages

-

Peter Wolters AC 400

2 Pages

-

Peter Wolters AC 2000

2 Pages

-

Peter Wolters AC 1000

2 Pages

-

Peter Wolters AC 700

2 Pages

-

Peter Wolters AC 535

2 Pages

-

Peter Wolters AC 1250

2 Pages

-

Peter Wolters DW 292

2 Pages

-

ELB smartLine

2 Pages

-

ELB millGrind

2 Pages

-

Elb-rotary

2 Pages

-

Peter Wolters AC 1500

2 Pages

-

Micron Macro-I

2 Pages

-

Micron Macro-SI

2 Pages

-

Kehren Ri

2 Pages

-

ISOG11

8 Pages

-

ISOG22

16 Pages

-

REFORM HSG

2 Pages

-

ISOG20

12 Pages

Archived catalogs

-

AC microLine 880 eco

2 Pages

-

AC microLine 1200 eco

2 Pages