Catalog excerpts

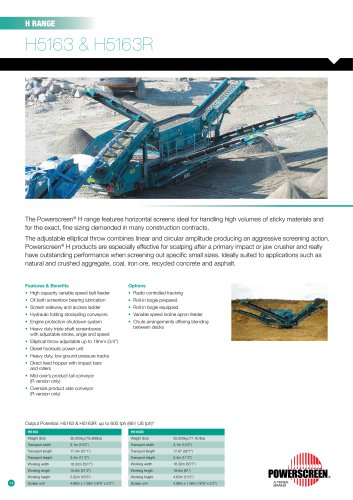

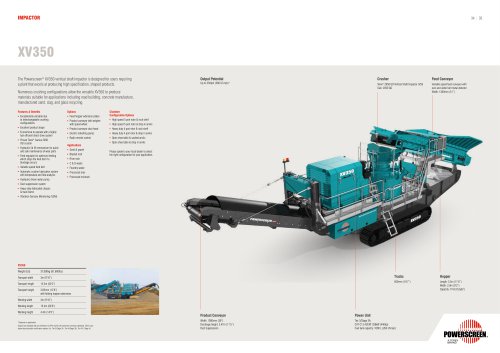

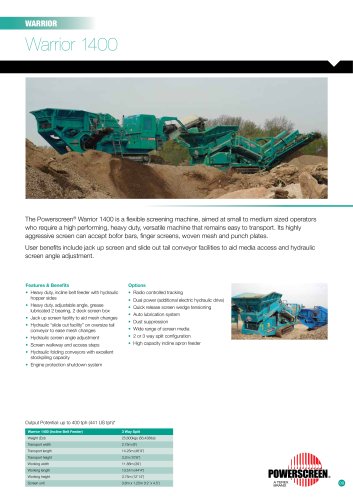

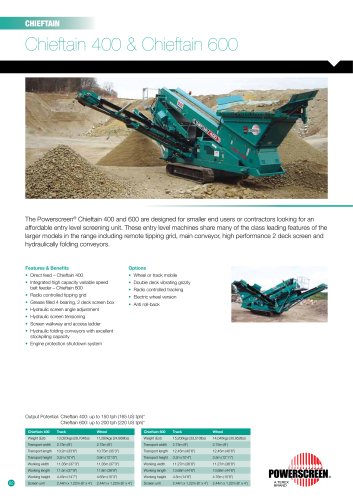

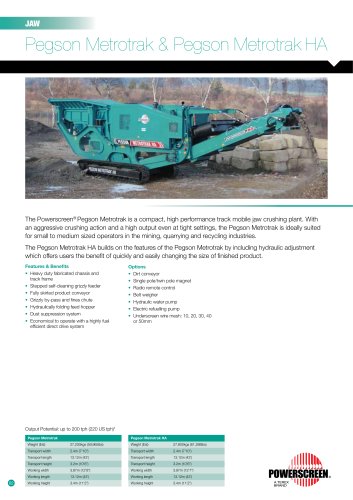

IMPACTOR XV350 Additional Product Ranges Screening Powerscreen designs and manufactures a world class range of mobile screening equipment boasting excellent productivity and reliability for our customers in the material processing industries. The core product range includes the Chieftain range of mobile incline screens designed for the processing of aggregates and sand; the Warrior range which are high capacity, heavy duty, versatile machines capable of screening and separating a wide variety of material; and the H range which feature horizontal screens for handling high volumes of sticky material and for fine sizing applications. Parts The Powerscreen® XV350 vertical shaft impactor is designed for users requiring a plant that excels at producing high specification, shaped products. Numerous crushing configurations allow the versatile XV350 to produce materials suitable for applications including road building, concrete manufacture, manufactured sand, slag, and glass recycling. Features & Benefits Options Chamber Configuration Options • Exceptionally versatile due to interchangeable crushing configurations • Feed hopper extension plates • High speed 5 port rotor and rock shelf • Excellent product shape • Feed hopper level sensor • Heavy duty 4 port rotor and rock shelf • Product conveyor dust shroud • Heavy duty 4 port rotor and drop in anvils • Electric refuelling pump • Open shoe table and vaulted anvils • Radio remote control • Open shoe table and drop in anvils • Feed regulator for optimum feeding which stops the feed belt if a blockage occurs Applications Please speak to your local dealer to select the right configuration for your application. • Variable speed feed belt • Blasted rock • Automatic crusher lubrication system with temperature and flow analysis Access to genuine Powerscreen® parts has never been easier, with each of our 120 dealers holding a wide range of parts specifically tailored to local requirements. Any part that is not immediately available can be ordered by your local dealer from our Parts Centres in Ireland, the USA and India. • High speed 5 port rotor and drop in anvils • Product conveyor belt weigher with speed wheel Powerscreen supplies a complete range of genuine crushing and screening spare parts that are designed specifically for use in Powerscreen® equipment. Use genuine Powerscreen® parts for performance and reliability. • River rock • Economical to operate with a highly fuel efficient direct drive system • Proven Terex® Canica 2050 VSI crusher • Hydraulic lid lift mechanism for quick and safe maintenance of wear parts • 3.5m (11’4”) product conveyor discharge height • Hydraulic driven water pump • Sand & gravel • C & D waste • Foundry waste • Processed ores • Dust suppression system • Heavy duty fabricated chassis & track frame • Processed minerals • Vibration Sensory Monitoring (VSM) Output Potential: up to 350 tph (386 US tph)* XV350 Weight (Est) 3m (9’10”) Transport length 15.3m (50’2”) Transport height 3.5m (11’6”) with folding hopper extensions Working width 3m (9’10”) Working length 12 37,000kg (81,600lbs) Transport width 15.4m (50’6”) Working height 4.4m (14’9”) 13

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

METROTRAK

2 Pages

-

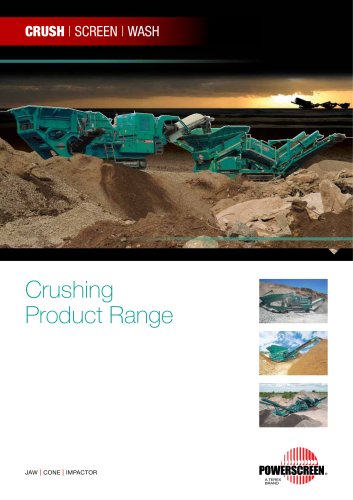

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

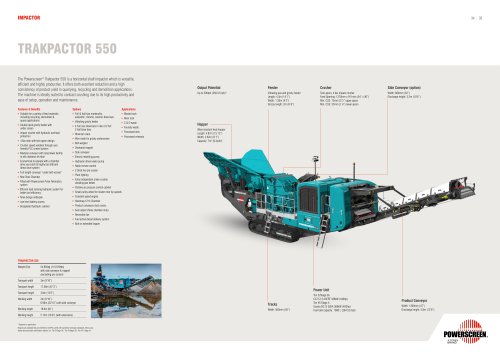

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

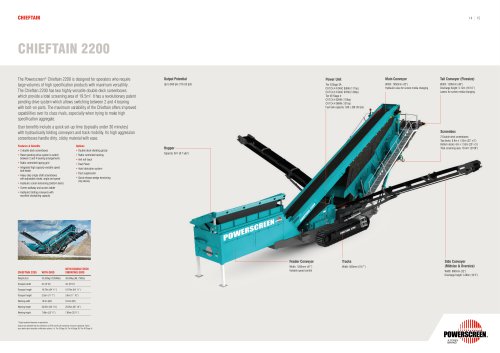

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

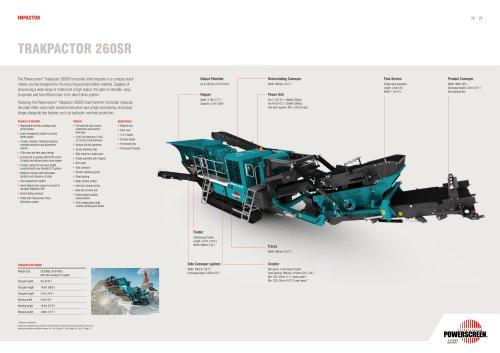

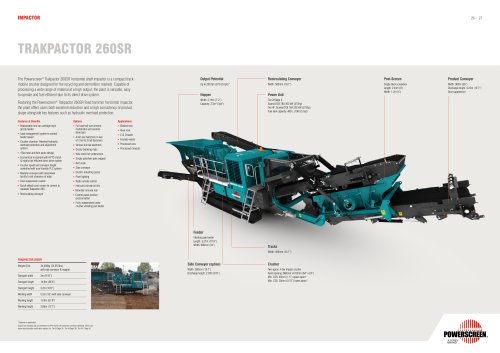

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

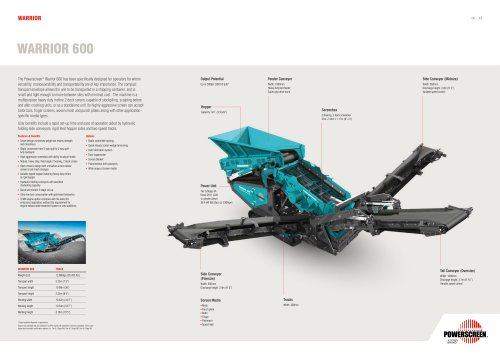

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XH250

1 Pages

-

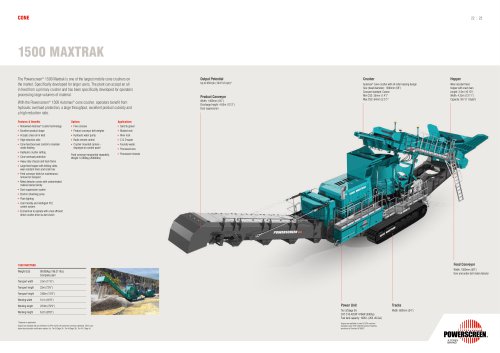

1500 Maxtrak

1 Pages

-

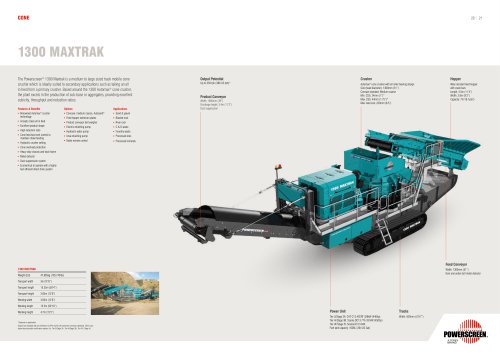

1300 Maxtrak

1 Pages

-

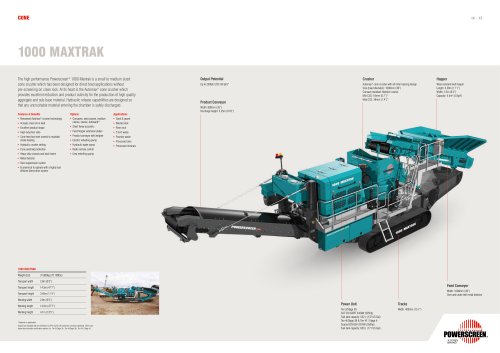

1000 Maxtrak & 1000SR

1 Pages

-

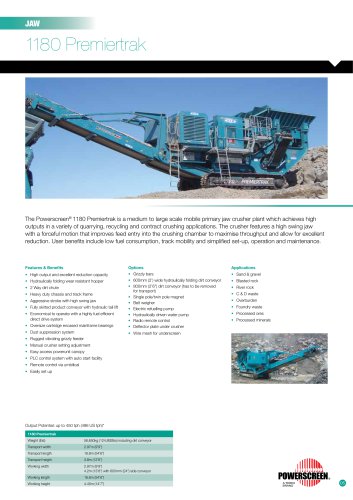

1180 Premiertrak

1 Pages

-

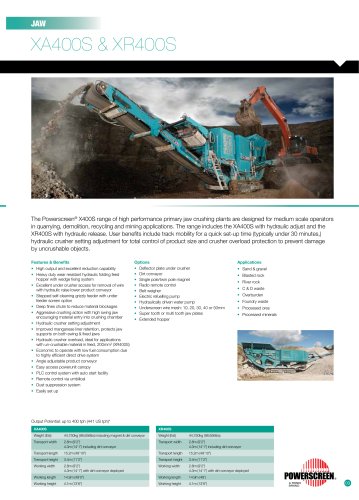

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

Warrior 1400

1 Pages

Archived catalogs

-

Powerscreen Mobile Crusher Range

16 Pages