Catalog excerpts

WARRIOR 2100 SPALECK The Warrior 2100 Spaleck screen is the ultimate in mobile screening and separation technology. At the heart of the product is the 2 deck high performance waste recycling screen featuring Flip-Flow-Screen technology. The unique stepped top deck design combined with state of the art Flip-Flow bottom deck puts this recycling screen into a class of its own for customers in many sectors of the waste recycling industry. The Warrior 2100 Spaleck screens suit a wide range of shapes and sizes and can be deployed in a variety of applications including Quarry, Coal, Scrap, Commercial Waste, Compost/Mulch/Soil, Slag/Ash and Auto Fluff due to the options available. Output Potential Side Conveyor (Finesize) Width: 900mm (35”) Discharge height: 3.93m (12’11”) Variable speed control Angle adjustable Screenbox 2 Deck screenbox Size: 4.88m x 1.55m (16’ x 5’) Spaleck 3D top deck with tumbling fingers Spaleck flip flow bottom deck Feeder Conveyor Width: 1300mm (51”) Heavy duty belt feeder Super grip drive drum Variable speed control Easy clean system under feeder Hopper Capacity: 7m3 (9.2yds3) Rigid one piece hopper Wear resistant steel Wing plates Features & Benefits 3D top deck screen media Flip-Flow bottom deck with quick clamping for easy removal Heavy duty inclined hopper Low engine running speed to improve fuel consumption Heavy duty, incline belt feeder Jack up screen facility to aid mesh changes Screen walkway and access steps Hydraulic folding conveyors with excellent stockpiling capacity ■ Rapid set-up and shutdown time Two speed tracks Reversible side conveyors Collection conveyor raise feature Options Radio controlled tracking 200mm (8”) Chassis riser Telescopic side conveyors Hydraulically folding hopper extensions High capacity incline apron feeder Quick release screen wedge tensioning Wide range of screen media Dust suppression Auto lubrication system Dual Power (additional electric hydraulic drive) 2 way split configuration ’Output potential depends on application Engines are available that are certified to US EPA and EU off road diesel emission standards. Talk to your dealer about possible certification options (i.e. Tier 3/Stage 3A, Tier 4i/Stage 3B, Tier 4F/Stage 4). Side Conveyor (Midsize) Width: 900mm (35”) Discharge height: 3.67m (12’) Variable speed control Angle adjustable Screen Media Top deck: Steel 3D punch plate Rubber 3D punch plate Rubber punch plate Steel punch plate Bottom deck: Dynamic flip flow Tail Conveyor (Oversize) Width: 1400mm (55”) Discharge height: 4.2m (13’9”) (3 Way Split) Discharge height: 3.5m (11’7”) (2 Way Split) Heavy duty impact bars Variable speed control Angle adjustable 0° - 24° Tracks Power Unit Tier 4F/Stage 4: CAT C4.4 93kW (125hp) Optional Constant Speed Engine (EU Only) Stage 3A Constant Speed: CAT C4.4 98kW (131hp) Fuel tank capacity: 336L (88 US Gal)

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

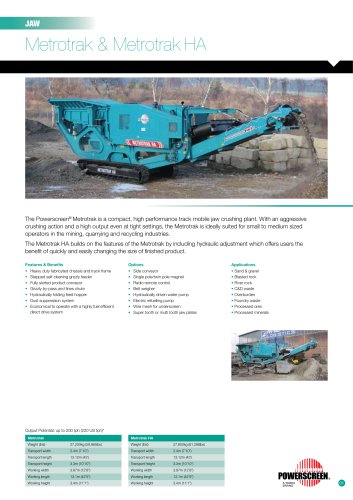

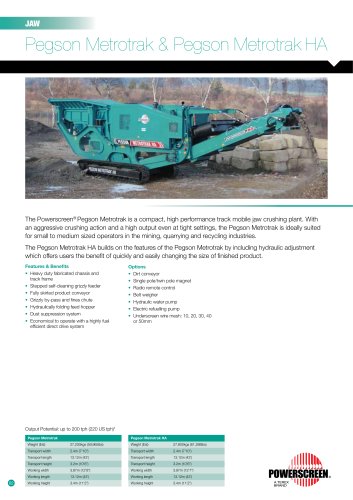

METROTRAK

2 Pages

-

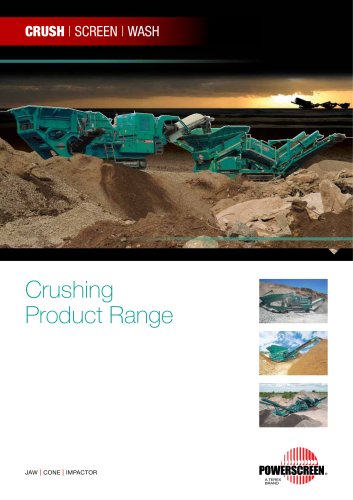

Crushing

25 Pages

-

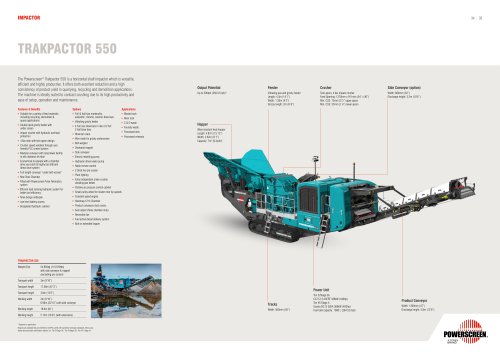

Trakpactor 550 Brochure

1 Pages

-

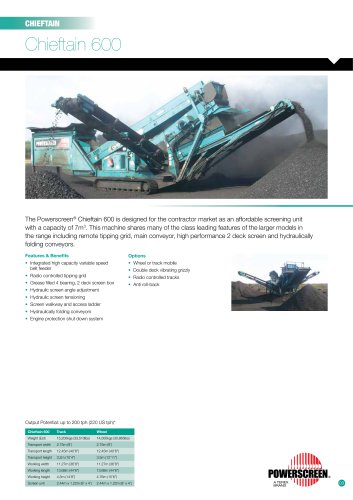

CHIEFTAIN 2200 3 DECK

1 Pages

-

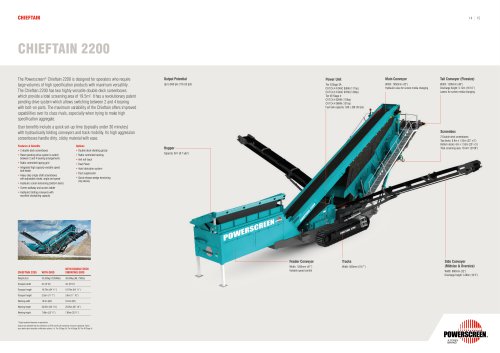

CHIEFTAIN 2200

1 Pages

-

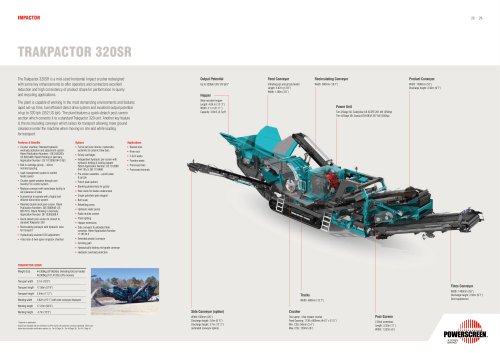

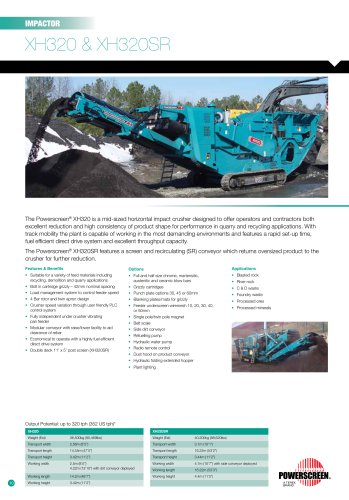

TRAKPACTOR 500

1 Pages

-

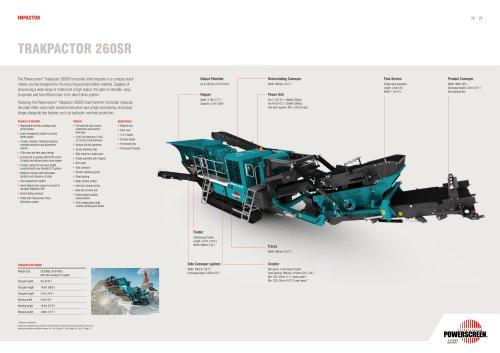

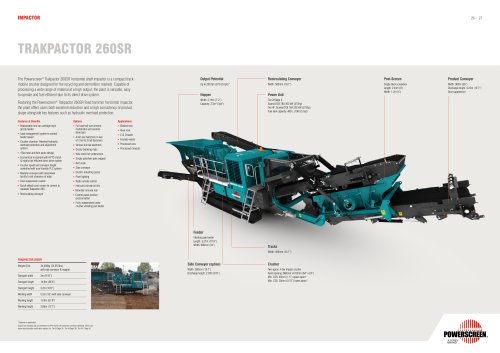

TRAKPACTOR 260SR

1 Pages

-

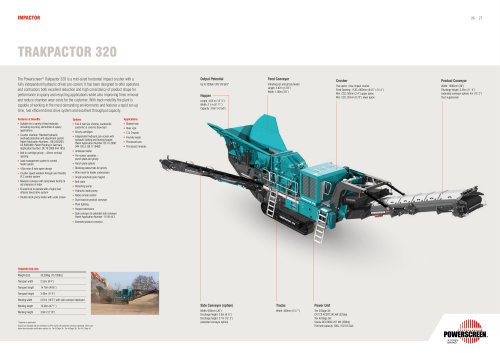

TRAKPACTOR 260

1 Pages

-

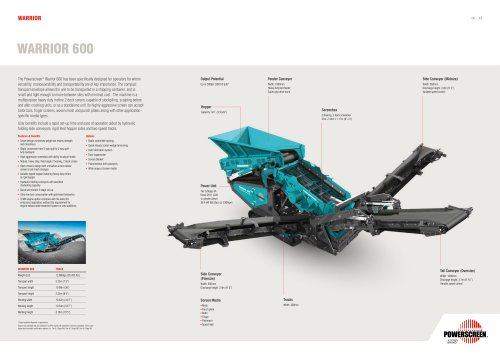

NEW Powerscreen Warrior 600

1 Pages

-

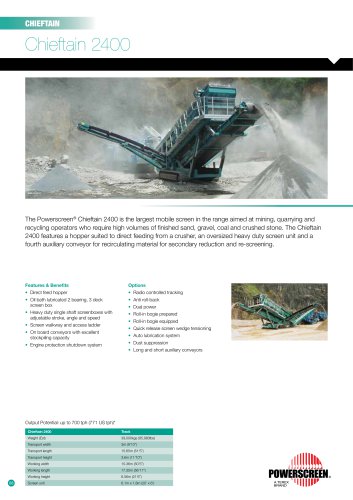

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

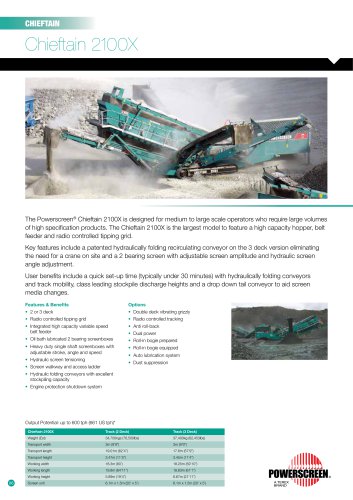

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

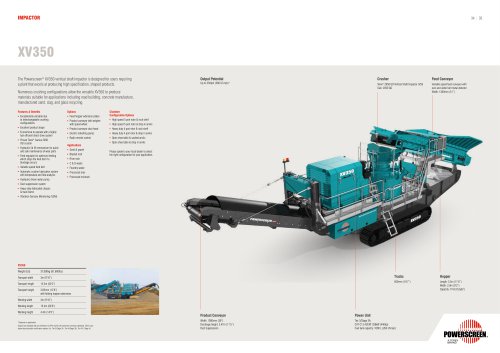

XV350

1 Pages

-

XH250

1 Pages

-

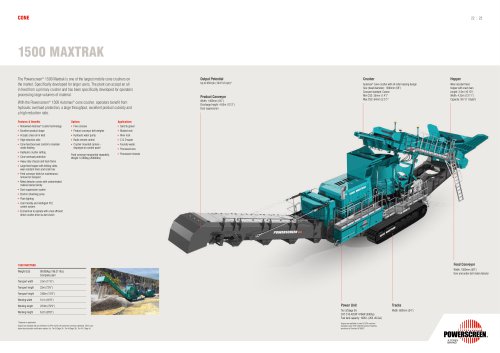

1500 Maxtrak

1 Pages

-

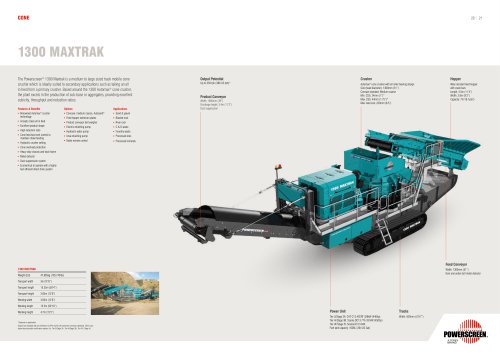

1300 Maxtrak

1 Pages

-

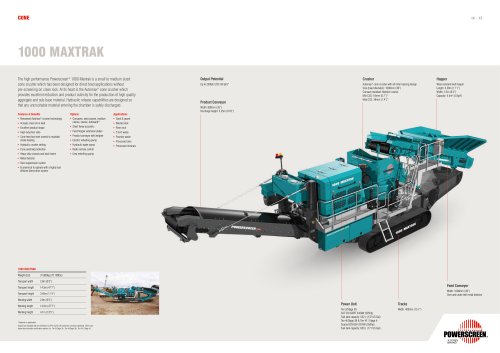

1000 Maxtrak & 1000SR

1 Pages

-

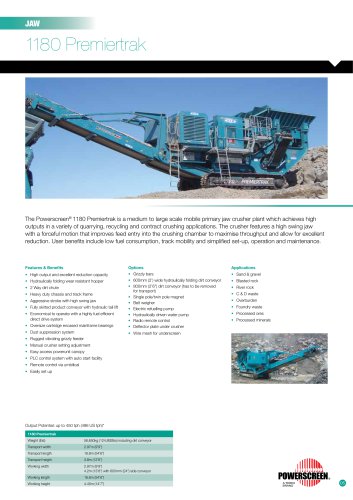

1180 Premiertrak

1 Pages

-

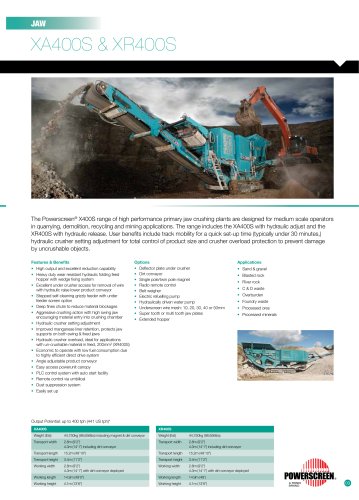

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

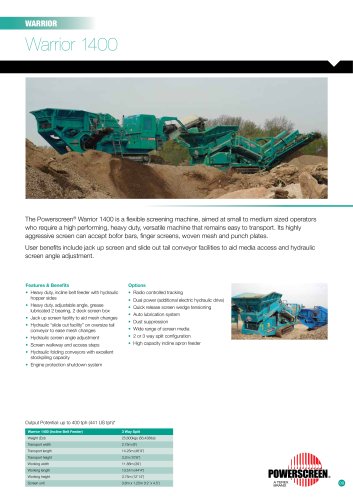

Warrior 1400

1 Pages

Archived catalogs

-

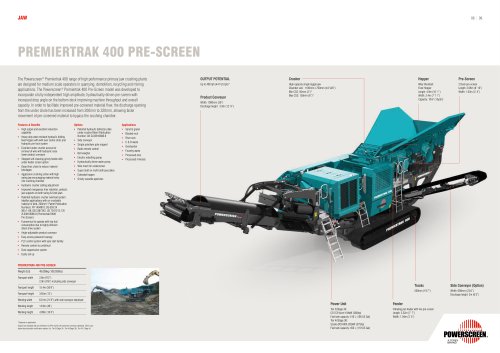

Powerscreen Mobile Crusher Range

16 Pages