Catalog excerpts

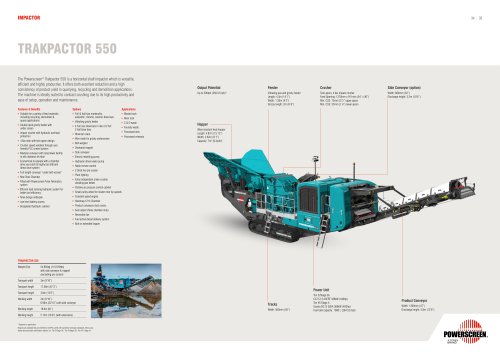

TRAKPACTOR 550 The Powerscreen® Trakpactor 550 is a horizontal shaft impactor which is versatile, efficient and highly productive. It offers both excellent reduction and a high consistency of product yield in quarrying, recycling and demolition applications. The machine is ideally suited to contract crushing due to its high productivity and ease of setup, operation and maintenance. Feeder Crusher Vibrating pan and grizzly feeder Length: 4.3m (14’1”) Width: 1.26m (4’2”) Grizzly length: 2m (6’6”) Twin apron, 4 bar impact crusher Feed Opening: 1370mm x 911mm (54” x 36”) Min. CSS: 75mm (3”)* upper apron Min. CSS: 35mm (1.4”) lower apron Side Conveyor (option) Width: 800mm (32”) Discharge height: 3.2m (10’6”) Features & Benefits Suitable for a variety of feed materials including recycling, demolition & quarry applications Double deck grizzly feeder with under screen Impact crusher with hydraulic overload protection 4 Bar rotor with twin apron design Crusher speed variation through user friendly PLC control system Modular conveyor with raise/lower facility to aid clearance of rebar Economical to operate with a chamber drive via clutch & highly fuel efficient direct drive system Full length conveyor "under belt version” New Terex Chamber Fitted with Powerscreen Pulse Telematics system Efficient load sensing hydraulic system for better fuel efficiency Terex design underpan Low level battery access Designated hydraulic cabinet Options Full & half size martensitic, austenitic, chrome, ceramic blow bars Vibrating grizzly feeder 4 Full size blow bars in lieu of 2 full 2 half blow bars Blow bar crane Wire mesh for grizzly underscreen Belt weigher Overband magnet Side conveyor Electric refuelling pump Hydraulic driven water pump Radio remote control 2 Deck live pre-screen Plant lighting Fully independent under crusher vibrating pan feeder Positive air pressure control cabinet Small pulley wheel for slower rotor tip speeds Constant speed engine Hazemag 1214 Chamber ■ Product conveyors dust covers Auto adjust (Terex chamber only) Reversible fan ■ Fuel active diesel delivery system ■ Bolt on extended hopper Applications Blasted rock River rock C & D waste Foundry waste Processed ores Processed minerals Weight (Est) 54,850kg (115,919lbs) with side conveyor & magnet (excluding pre-screen) Transport width 3m (9’10”) Working height 5.15m (16’9”) (with extensions) Product Conveyor Width: 1200mm (47”) Discharge height: 3.8m (12’6”) “Depends on application Engines are available that are certified to US EPA and EU off road diesel emission standards. Talk to your dealer about possible certification options (i.e. Tier 3/Stage 3A:, Tier 4i/Stage 3B:, Tier 4F / Stage 4).

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

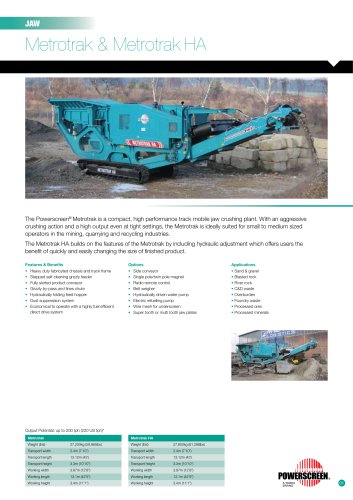

METROTRAK

2 Pages

-

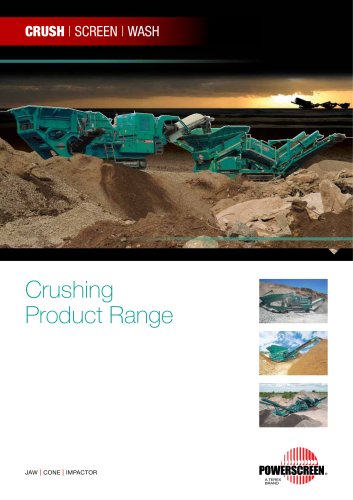

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

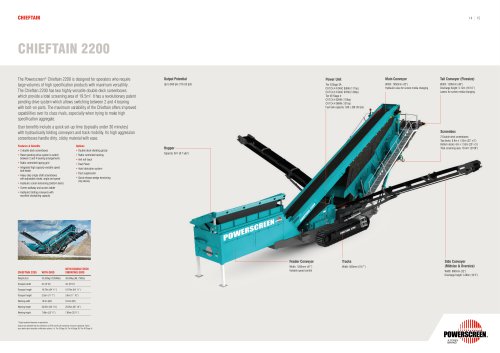

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

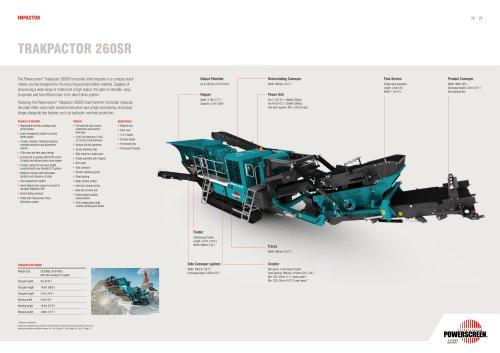

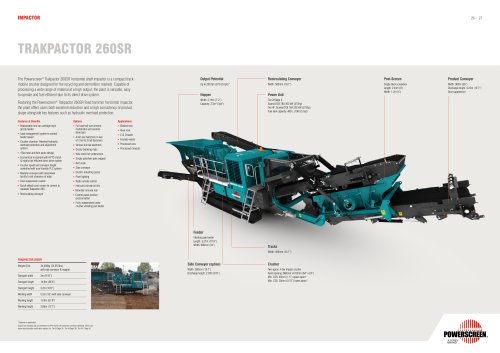

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

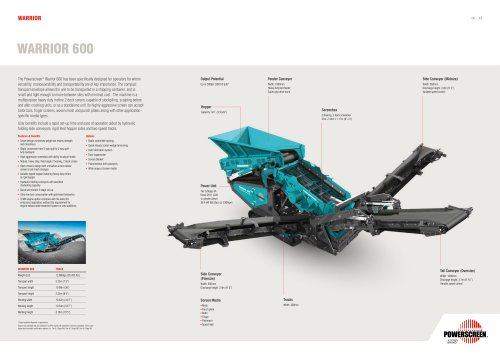

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

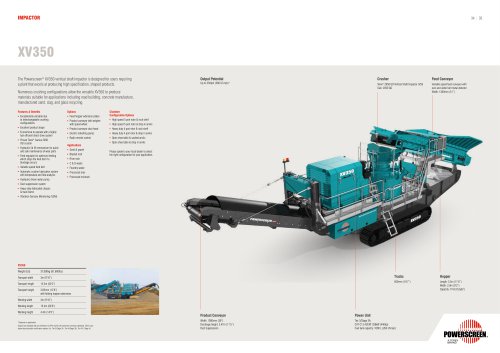

XV350

1 Pages

-

XH250

1 Pages

-

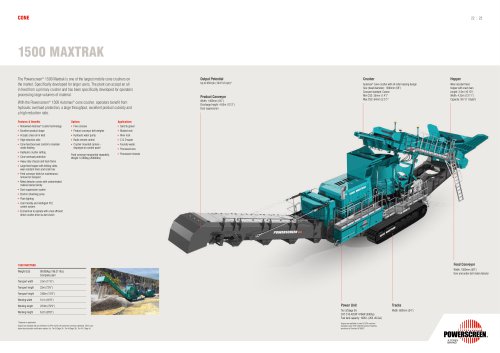

1500 Maxtrak

1 Pages

-

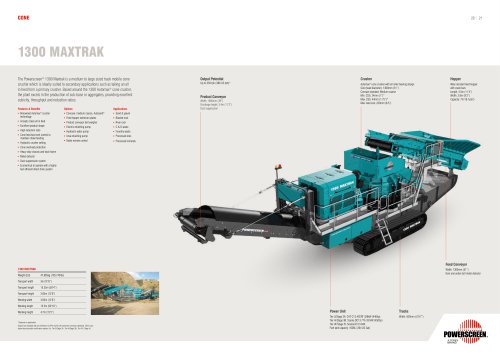

1300 Maxtrak

1 Pages

-

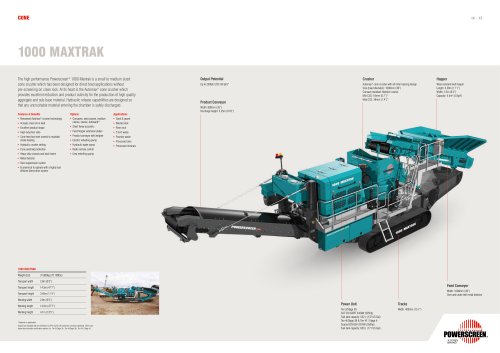

1000 Maxtrak & 1000SR

1 Pages

-

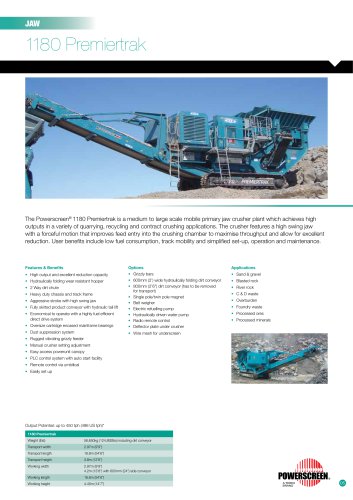

1180 Premiertrak

1 Pages

-

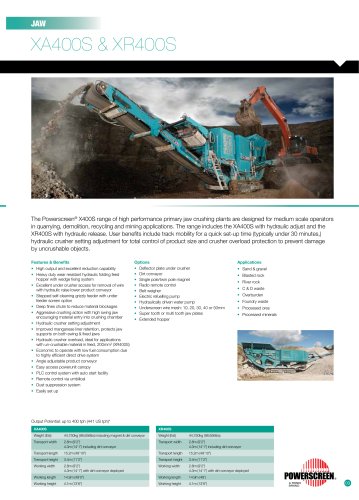

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

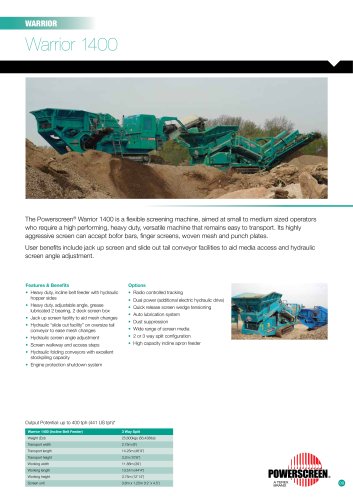

Warrior 1400

1 Pages

Archived catalogs

-

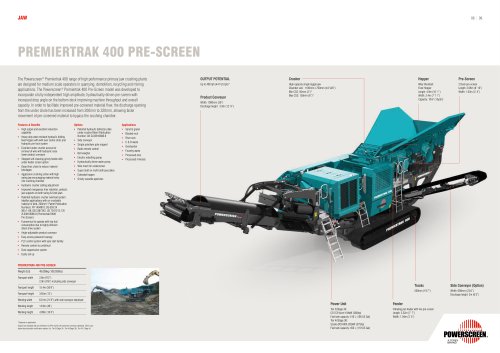

Powerscreen Mobile Crusher Range

16 Pages