Catalog excerpts

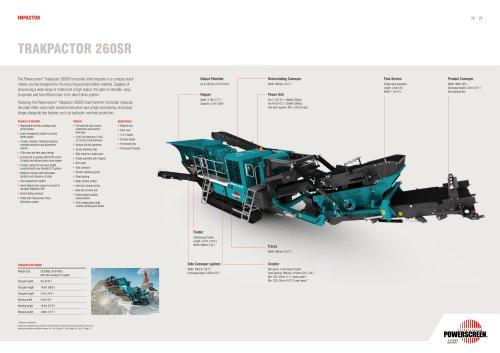

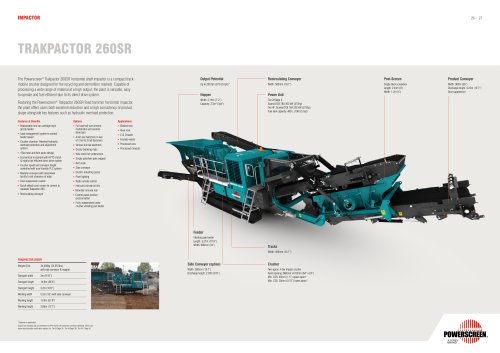

TRAKPACTOR 260SR The Powerscreen® Trakpactor 260SR horizontal shaft impactor is a compact track mobile crusher designed for the recycling and demolition markets. Capable of processing a wide range of material at a high output, the plant is versatile, easy to operate and fuel efficient due to its direct drive system. Featuring the Powerscreen® Trakpactor 260SR fixed hammer horizontal impactor, the plant offers users both excellent reduction and a high consistency of product shape alongside key features such as hydraulic overload protection. Recirculating Conveyor Width: 500mm (19.7") Post-Screen Single deck screenbox Length: 2.44m (8') Width: 1.2m (4') Product Conveyor Width: 900m (36") Discharge height: 3.25m (107”) Dust suppression Features & Benefits Replaceable tine bar cartridge style grizzly feeder Load management system to control feeder speed Crusher chamber: Patented hydraulic overload protection and adjustment system. 4 Bar rotor and twin apron design Economical to operate with HPTO clutch & highly fuel efficient direct drive system Crusher speed and conveyor height controlled with user-friendly PLC system Modular conveyor with raise/lower facility to aid clearance of rebar Dust suppression system Options Full and half size chrome, martensitic and ceramic blow bars 4 full size hammers in lieu of 2 full & 2 half hammers Various tine bar apertures Grizzly blanking mats Wire mesh for underscreen Single pole/twin pole magnet Belt scale Side conveyor Electric refuelling pump Plant lighting Radio remote control Applications Blasted rock River rock C & D waste Foundry waste Processed ores Processed minerals Quick-detach post-screen to convert to standard Trakpactor 260 Recirculating conveyor Fitted with Powerscreen Pulse Telematics system Hot/cold climate oil kits Blow Bar removal tool Control panel positive pressurisation Fully independent under crusher vibrating pan feeder Feeder Vibrating pan feeder Length: 3.27m (10'9”) Width: 800mm (32”) TRAKPACTOR 260SR Weight (Est) 33,950kg (74,847lbs) with side conveyor & magnet Transport width 3m (9'10”) Side Conveyor (option) Width: 500mm (19.7”) Discharge height: 2.03m (6'8”) Crusher Twin apron, 4 bar impact crusher Feed opening: 860mm x 610mm (34” x 24”) Min. CSS: 40mm (1.5”) upper apron* Min. CSS: 20mm (0.75”) lower apron* “Depends on application Engines are available that are certified to US EPA and EU off road diesel emission standards. Talk to your dealer about possible certification options (i.e. Tier 3/Stage 3A:, Tier 4i/Stage 3B:, Tier 4F / Stage 4).

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

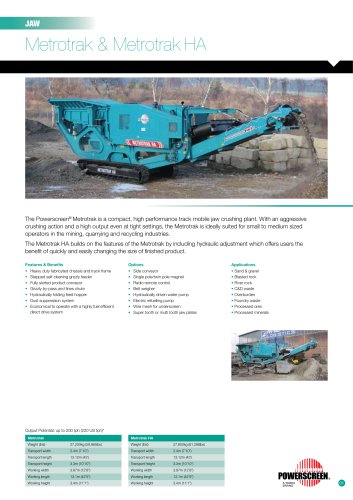

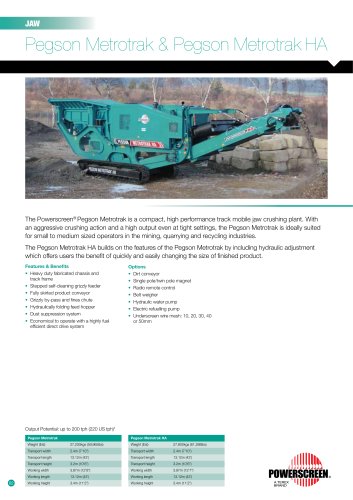

METROTRAK

2 Pages

-

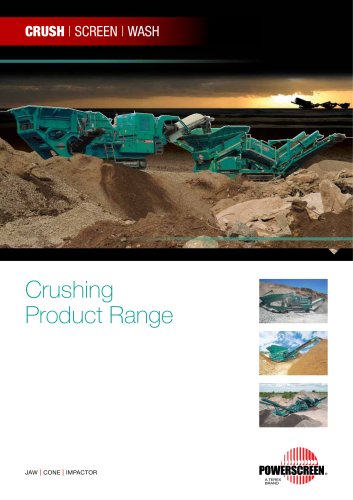

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

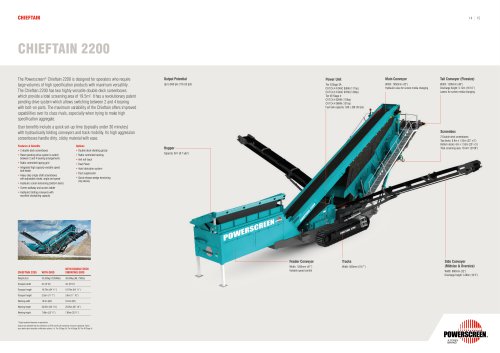

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

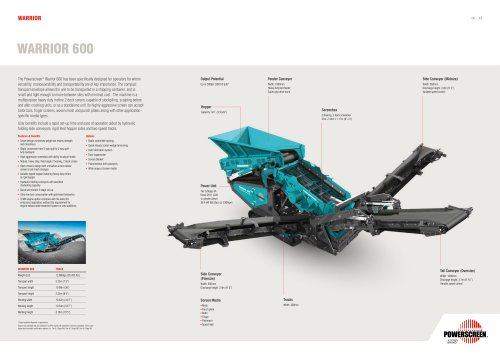

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

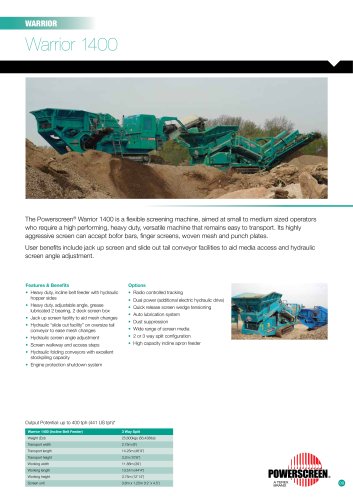

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XV350

1 Pages

-

XH250

1 Pages

-

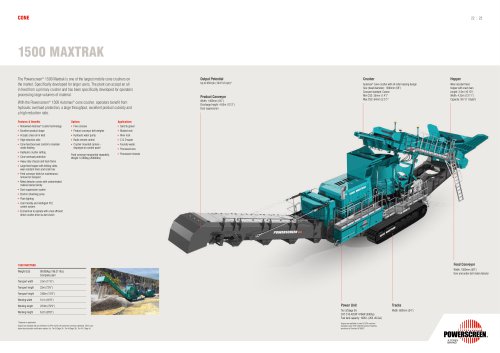

1500 Maxtrak

1 Pages

-

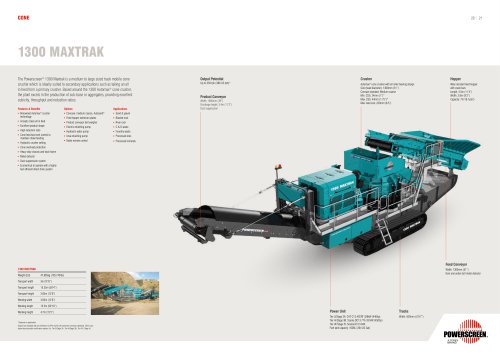

1300 Maxtrak

1 Pages

-

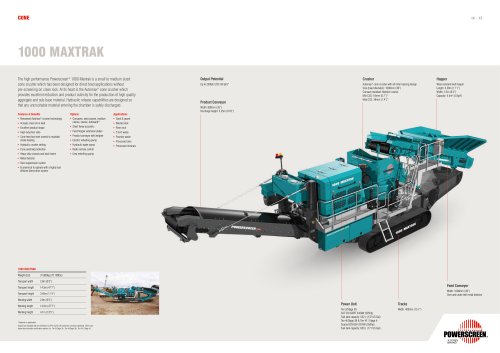

1000 Maxtrak & 1000SR

1 Pages

-

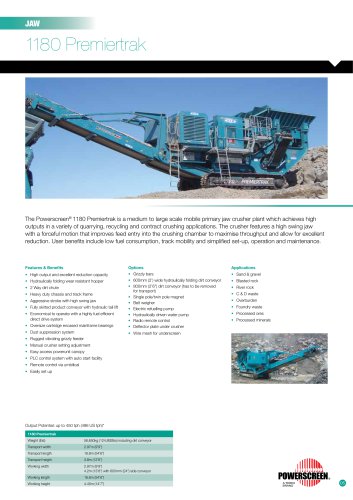

1180 Premiertrak

1 Pages

-

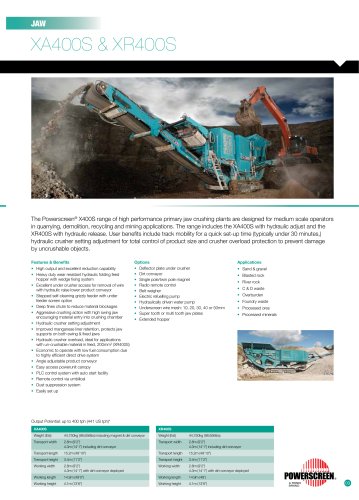

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

Warrior 1400

1 Pages

Archived catalogs

-

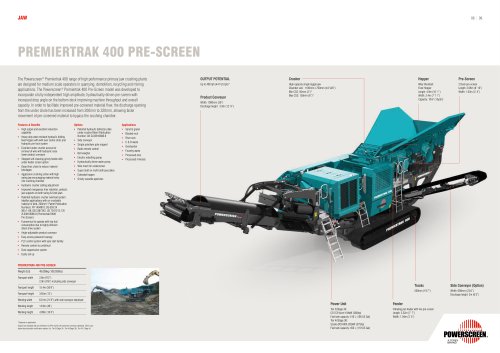

Powerscreen Mobile Crusher Range

16 Pages