Catalog excerpts

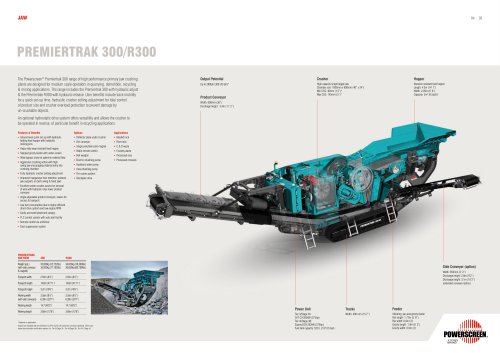

PREMIERTRAK 330 The Powerscreen® Premiertrak range of high performance primary jaw crushing plants are designed for operators in quarrying, demolition, recycling & mining applications. The range includes the Premiertrak 330 which boasts a two piece grizzly feeder allowing better material flow towards the chamber. User benefits include track mobility for a quick set-up time, variable crusher speed giving the operator more ability to fine tune the machine to the application and maximise output. Hopper Wear resistant feed hopper Length: 4.46m (14’8”) Width: 2.05m (6’8”) standard 2.8m (9’2”) with extensions Capacity: 5m3 (6.5yds ) Feeder Vibrating pan and grizzly feeder Pan length: 3.65m (12’) Pan width: 0.9m (2’11”) Grizzly length: 1.9m (6’ 3”) Grizzly width: 0.9m (2' 11”) Crusher Power Unit Terex chamber single toggle jaw Tier 3/Stage 3A: Chamber size: 1000mm x 600mm (39” x 23.6”) John Deere 6068 212 kW (284hp) A hydrostatic drive system offers versatility and allows the crusher to be operated in reverse, of particular benefit in recycling applications. Features & Benefits Simple large feed hopper manufactured from 8mm wear plate Two piece Grizzly feeder with second section angled Large under jaw clearance with hydraulically lowered conveyor with optional radio control for clearing blockages Push button Jaw CSS Variable crusher speed Bypass chute with adjustable deflector plate to switch between product & dirt conveyor Large screen area on Vibrating Grizzly Feeder Feeder Advanced control system with simple auto-start function and easy change of settings Engine speed & hydraulic system optimised to reduce losses & maximise fuel efficiency Hydrostatic Drive allows reversibility of the chamber Easily accessed power unit canopy Low engine speed Remote control via umbilical Dust suppression system Fitted with Powerscreen Pulse Telematics system Options Hydraulic deflector plate Bypass conveyor Single pole'twin pole magnet Radio remote control Belt weigher Extended hopper Hydraulic water pump Deflector plate adjustment Applications Blasted rod River rod C & D waste Foundry waste Processed ores Processed minerals Weight (est.) with side conveyor & magnet 34.860kg (76,850lbs) Product Conveyor Transport width 2.6m (8'9”j Width: 900mm W”) Discharge height: 3.5m ino”) Bypass Conveyor (option) Tracks Width: 650mm (26”) Width: 400mm (15.7”) *Depends on application Engines are available that are certified to US EPA and EU off road diesel emission standards. Talk to your dealer about possible certification options (i.e. Tier 3/Stage 3A:, Tier 4i/Stage 3B:, Tier 4F / Stage 4). POWERSCREEN. ATEREX BRAND

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

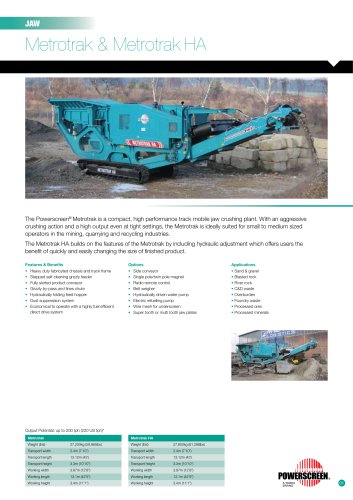

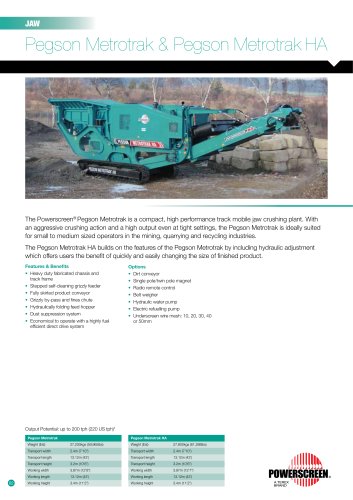

METROTRAK

2 Pages

-

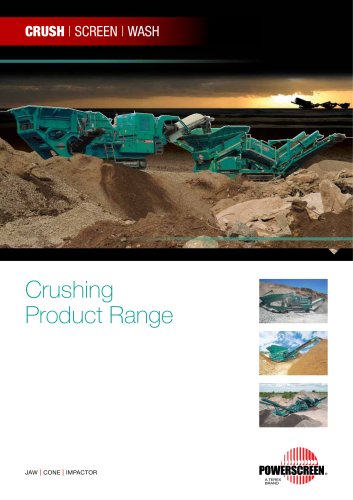

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

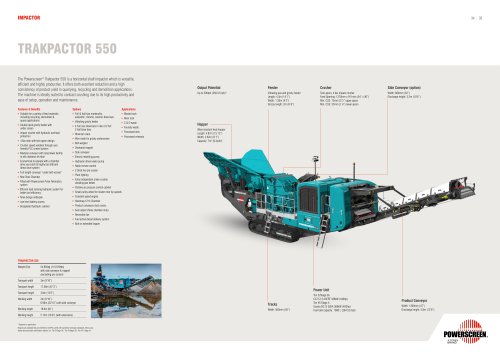

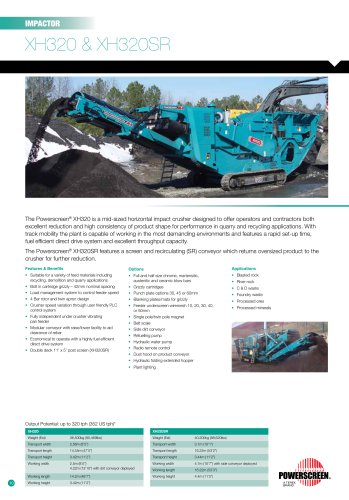

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

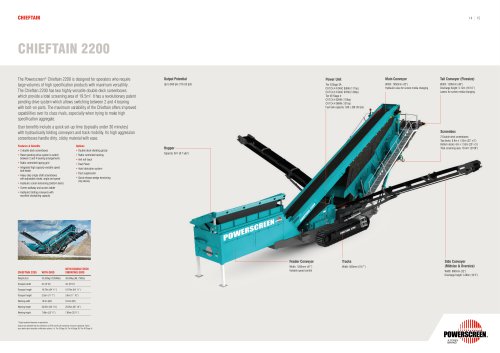

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

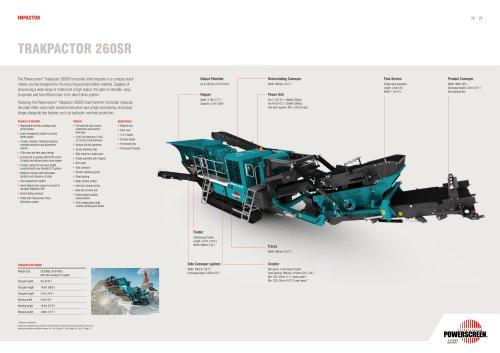

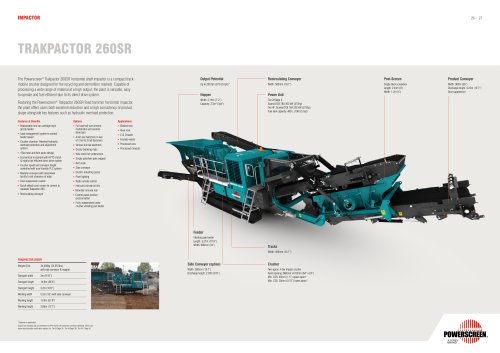

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

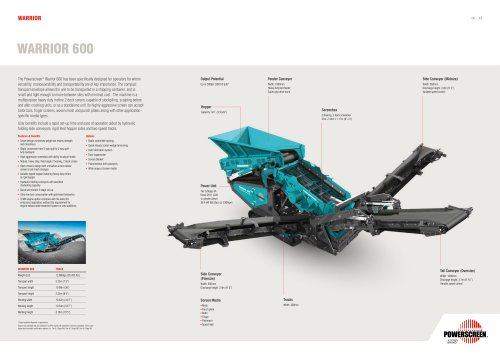

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XV350

1 Pages

-

XH250

1 Pages

-

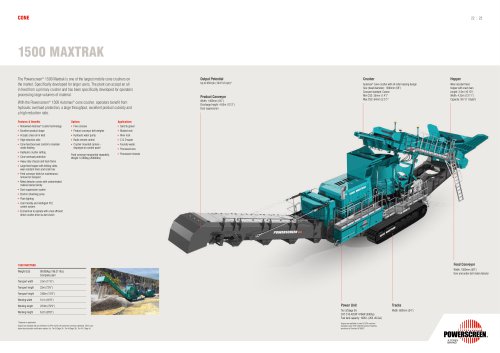

1500 Maxtrak

1 Pages

-

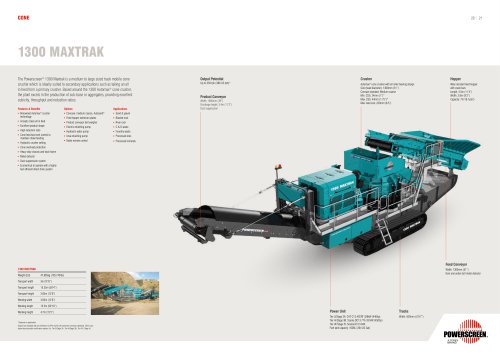

1300 Maxtrak

1 Pages

-

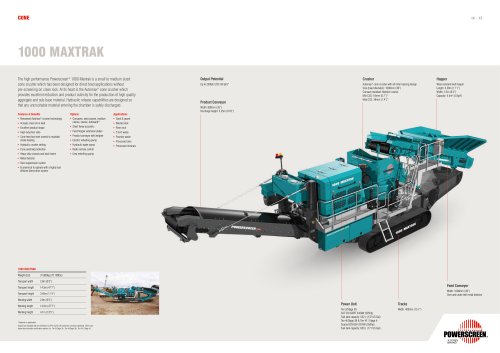

1000 Maxtrak & 1000SR

1 Pages

-

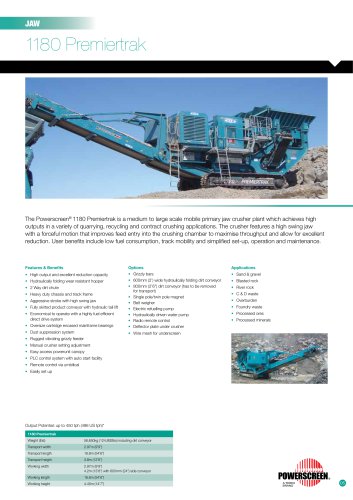

1180 Premiertrak

1 Pages

-

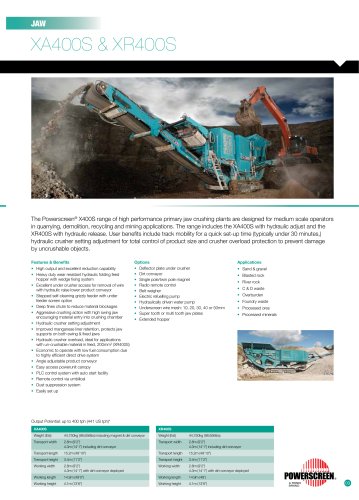

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

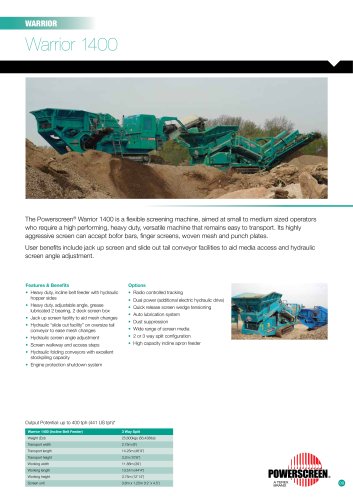

Warrior 1400

1 Pages

Archived catalogs

-

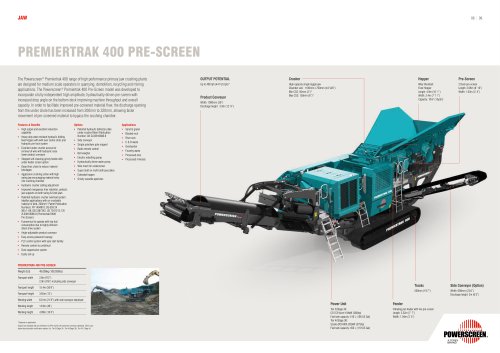

Powerscreen Mobile Crusher Range

16 Pages