Catalog excerpts

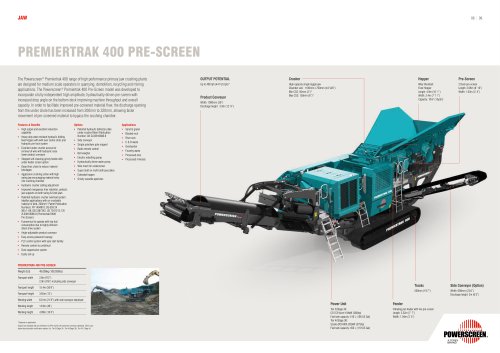

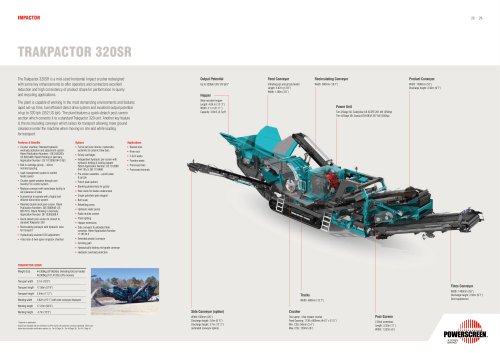

TRAKPACTOR 320SR The Trakpactor 320SR is a mid-sized horizontal impact crusher redesigned with some key enhancements to offer operators and contractors excellent reduction and high consistency of product shape for performance in quarry and recycling applications. Output Potential Crusher chamber: Patented hydraulic overload protection and adjustment system. Patent Publication Numbers : GB 2455203; US 8033489. Patent Pending in Germany, Application Number : DE 10 2008 044 1953 Bolt in cartridge grizzly – 42mm nominal spacing Load management system to control feeder speed Crusher speed variation through user friendly PLC control system Modular conveyor with raise/lower facility to aid clearance of rebar Recirculating Conveyor Product Conveyor Vibrating pan and grizzly feeder Length: 3.87m (12’8”) Width: 1.08m (3’6”) The plant is capable of working in the most demanding environments and features rapid set-up time, fuel efficient direct drive system and excellent output potential of up to 320 tph (352 US tph). The plant features a quick-detach post-screen section which converts it to a standard Trakpactor 320 unit. Another key feature is the recirculating conveyor which raises for transport allowing more ground clearance under the machine when moving on site and while loading for transport. Features & Benefits Feed Conveyor Wear resistant hopper Length: 4.04 m (13’ 3”) Width: 2.1 m (6’ 11”) Capacity: 3.6m3 (4.7yd3) Full & half size chrome, martensitic, austenitic & ceramic blow bars Blasted rock Grizzly cartridges Independent hydraulic pre-screen with hydraulic folding & locking hopper. Patent Application Number: DE 10 2008 044 195.3; GB 1119480 River rock Foundry waste Processed ores Processed minerals Pre-screen cassettes – punch plate & grizzly Punch plate options Blanking plates/mats for grizzly Wire mesh for feeder underscreen Economical to operate with a highly fuel efficient direct drive system Single pole/twin pole magnet Patented double deck post-screen. Patent Publication Numbers: GB 2386848; US 6877610. Patent Pending in Germany, Application Number: DE 10305589.4 Refuelling pump Quick-detach post-screen to convert to standard Trakpactor 320 Plant lighting Recirculating conveyor with hydraulic raise for transport Hydraulically assisted CSS adjustment Side conveyor & extended Side conveyor. Patent Application Number: 1118144.3 4 Bar rotor & twin apron impactor chamber Extended product conveyor Belt scale Hydraulic water pump Radio remote control Hopper extensions Grinding path Hydraulically folding mid-grade conveyor Hydraulic overload protection 44,300kg (97,665lbs) (Vibrating Grizzly Feeder) 46,000kg (101,412lbs) (Pre-Screen) Transport width Fines Conveyor Transport length 17.58m (57’8”) Transport height 3.44m (11’2”) Working width 5.82m (19’1”) with side conveyor deployed Working length Working height Width: 1400mm (55”) Discharge height: 2.92m (9’7”) Dust suppression *Depends on application Engines are available that are certified to US EPA and EU off road diesel emission standards. Talk to your dealer about possible certification options (i.e. Tier 3/Stage 3A:, Tier 4i/Stage 3B:, Tier 4F / Stage 4). Side Conveyor (option) Width: 650mm (26”) Discharge height: 2.6m (8’ 6”) Discharge height: 3.7m (12’ 2”) (extended conveyor option) Twin apron, 4 bar impact crusher Feed Opening: 1130 x 800mm (44.5” x 31.5”) Min. CSS: 50mm (2.4”) Max. CSS: 150mm (6”) Post-Screen 2 Deck screenbox Length: 3.35m (11’ ) Width: 1.525m (5’)

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

METROTRAK

2 Pages

-

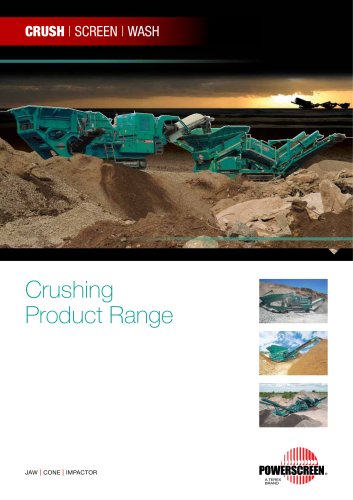

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

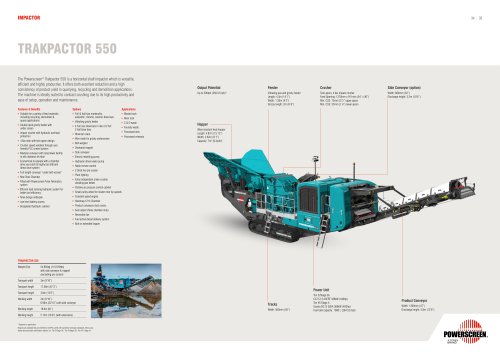

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

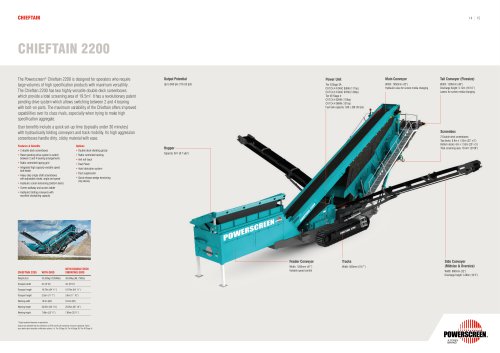

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

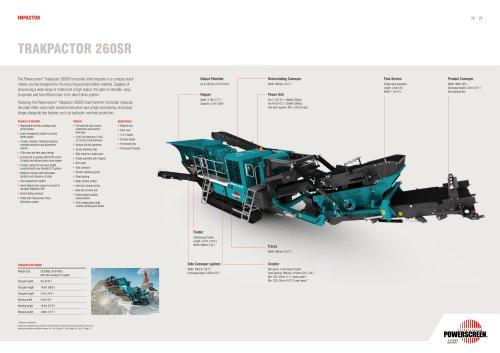

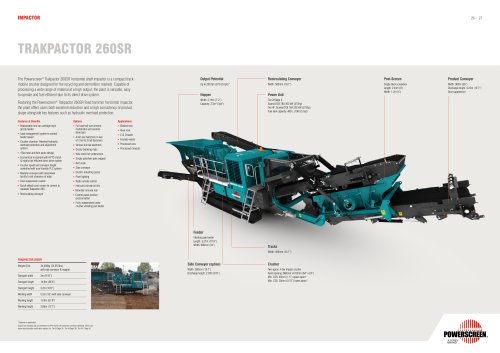

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

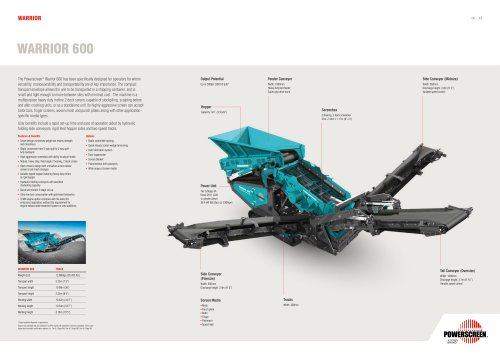

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

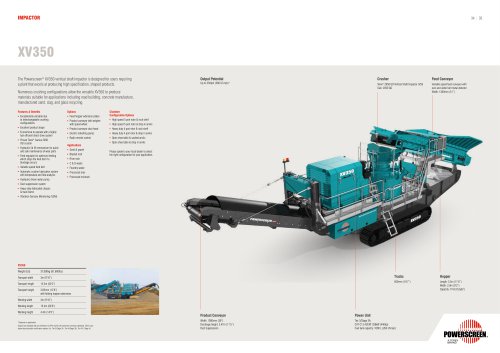

XV350

1 Pages

-

XH250

1 Pages

-

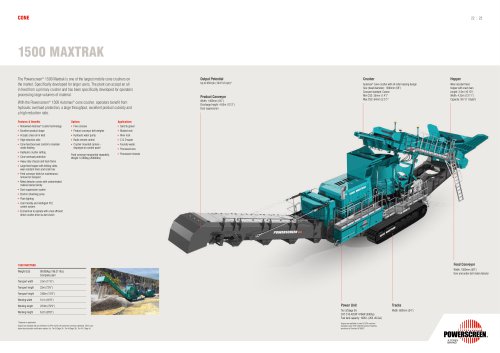

1500 Maxtrak

1 Pages

-

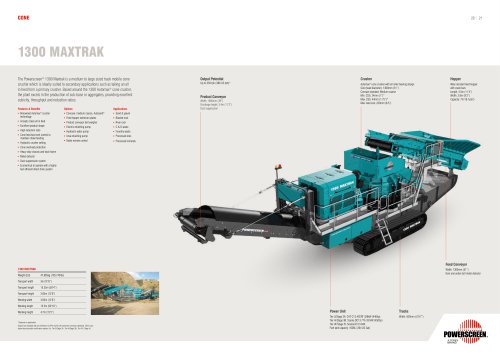

1300 Maxtrak

1 Pages

-

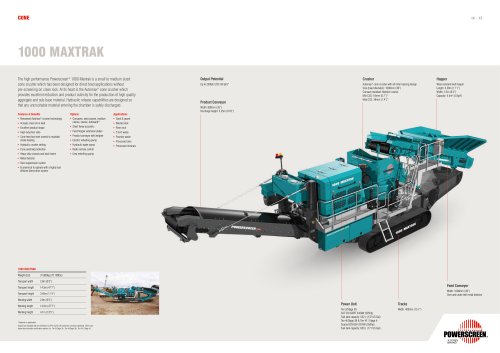

1000 Maxtrak & 1000SR

1 Pages

-

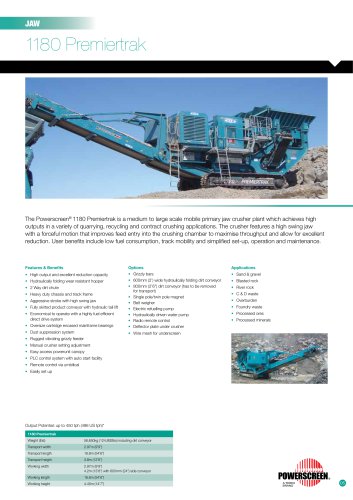

1180 Premiertrak

1 Pages

-

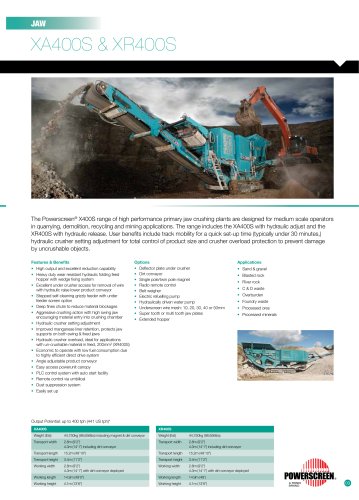

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

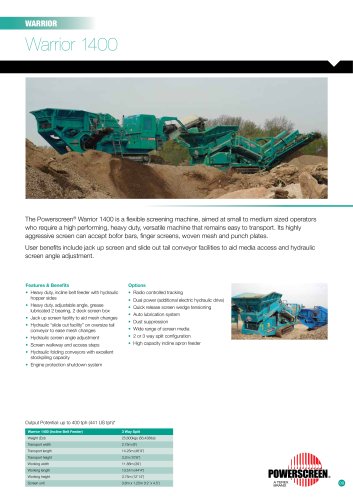

Warrior 1400

1 Pages

Archived catalogs

-

Powerscreen Mobile Crusher Range

16 Pages