Catalog excerpts

The Powerscreen® Premiertrak 750 jaw crusher is one of the most advanced and efficient tracked crushing plants on the market for large scale operators. The Premiertrak 750 is capable of producing high volumes of excellently shaped product. Key features include an unrestricted feed opening which maintains high production capacities and prevents bridging, a hydraulic closed side setting adjustment system and a hydraulic draw back rod retention system. User benefits include hydraulically adjustable product conveyor for ease of transport and low running costs associated with the direct drive crusher system. Features & Benefits • High output and excellent reduction capabilities • Hydraulic folding hopper with over centre struts and wedgelock system • 2 deck live pre-screen, allows fines & sizes to be removed, minimises packing & unnecessary manganese wear • Hydraulic draw back mechanism keeps jaw stock in tension on toggle plate • Excellent under crusher access with a hydraulic tilting conveyor system • Fuel efficient direct drive system • Modular product conveyor with raise/lower facility to aid rebar clearance, transport & maintenance • Low running costs & fuel consumption due to direct crusher drive & efficient plant controls • Highly efficient, hydraulically operated self adjusting dry plate clutch, featuring PLC controlled “push button” start up sequence • Modular heavy duty chassis and track frame, hopper can be removed for transport, (Hopper/feeder module) • Grizzly bars • 800mm (2’6”) wide hydraulically folding dirt conveyor • Single pole/twin pole magnet • Radio remote control • Belt weigher • Optical belt weigher • Product conveyor dust shroud • Pre-screen media • Electric refuelling pump • Transport beam • Maintenance platform • Blasted rock • Hydraulically driven water pump • Underscreen wire mesh: 20, 30, 40, 50 or 75mm Output Potential: up to 750 tph (827 US tph)* Premiertrak 750 Weight (Est) 3.41m (11’2”) with left hand side walkway Transport length Transport height Working width 3.85m (12’8”) 8.55m (28’) with side conveyor deployed Working length 74,500kg (164,244 lbs) including side conveyor & magnet Transport width Working height • River rock • C & D waste • Foundry waste • Processed ores

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

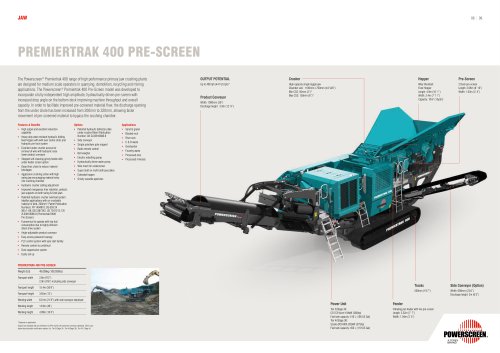

PREMIERTRAK 330

1 Pages

-

METROTRAK

2 Pages

-

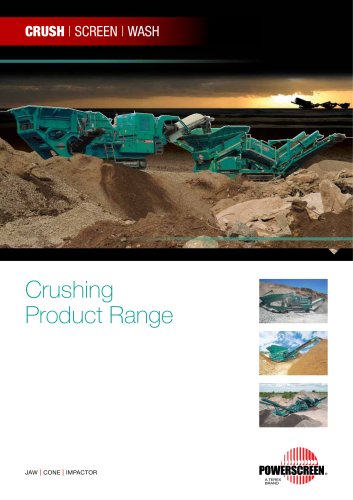

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

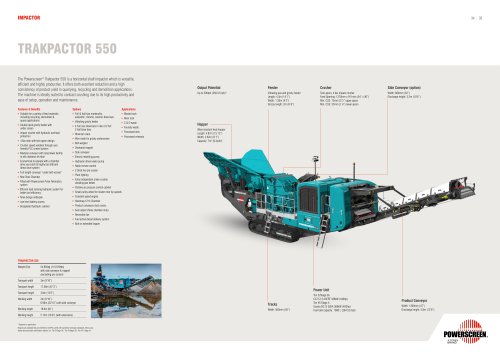

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

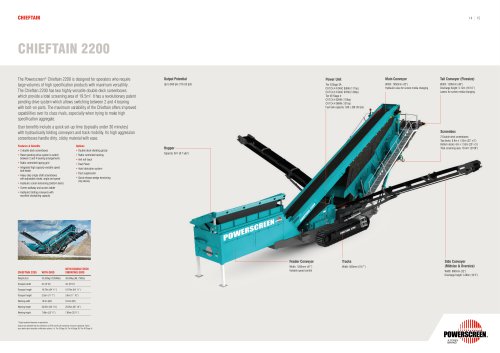

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

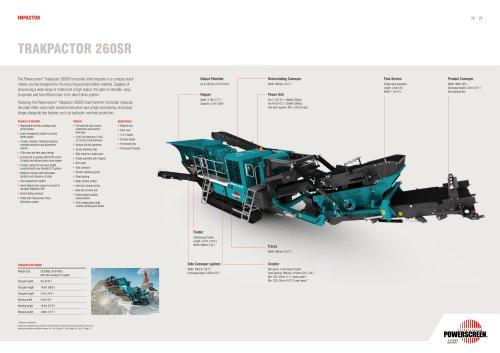

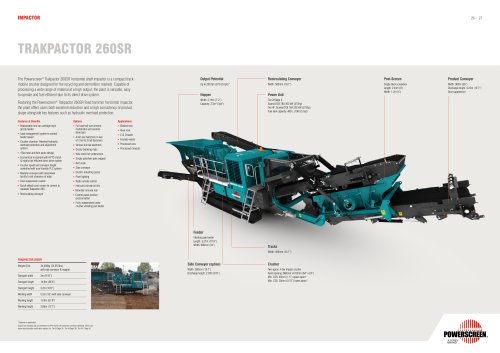

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

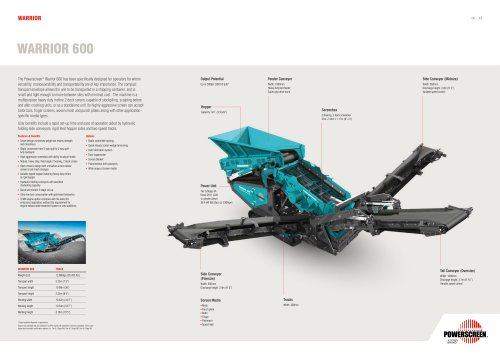

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XV350

1 Pages

-

XH250

1 Pages

-

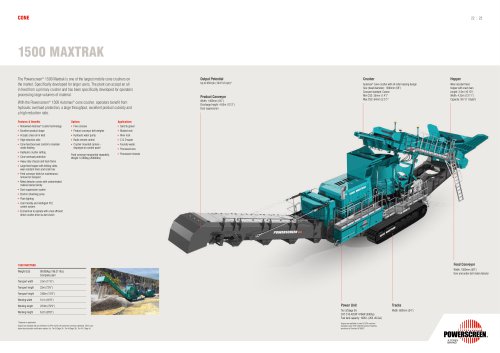

1500 Maxtrak

1 Pages

-

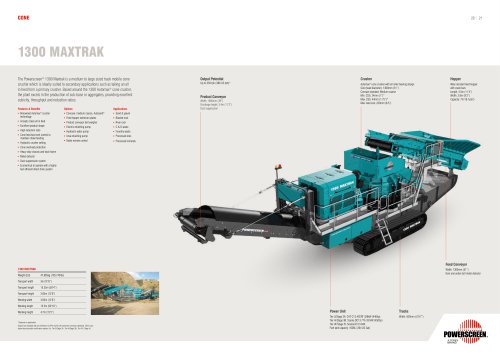

1300 Maxtrak

1 Pages

-

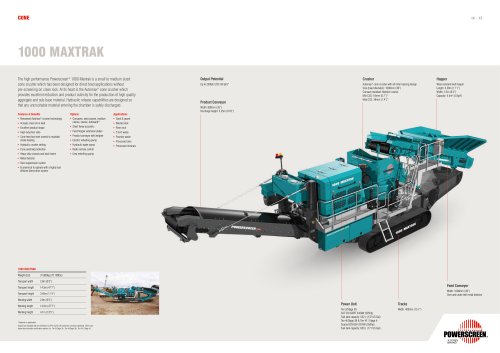

1000 Maxtrak & 1000SR

1 Pages

-

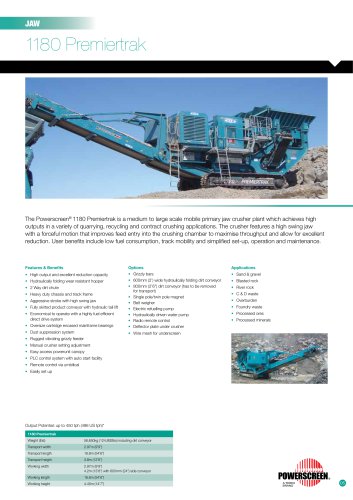

1180 Premiertrak

1 Pages

-

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

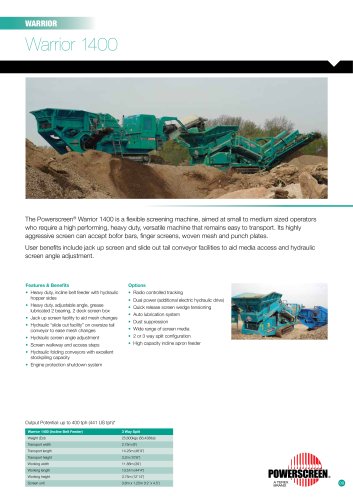

Warrior 1400

1 Pages

Archived catalogs

-

Powerscreen Mobile Crusher Range

16 Pages