Catalog excerpts

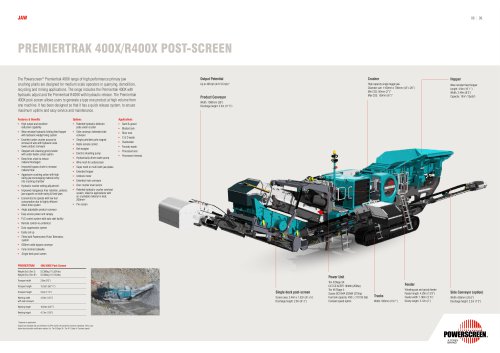

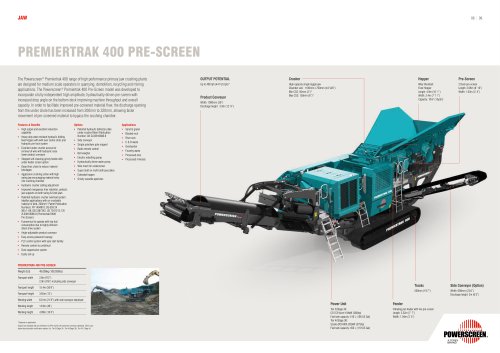

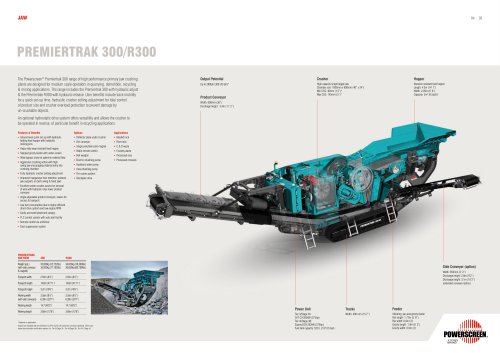

The Powerscreen® Premiertrak 400 range of high performance primary jaw crushing plants are designed for medium scale operators in quarrying, demolition, recycling and mining applications. The range includes the Premiertrak 400 with hydraulic adjust and the XR400S with hydraulic release. User benefits include track mobility for a quick set-up time (typically under 30 minutes,) hydraulic crusher setting adjustment for total control of product size and crusher overload protection to prevent damage by uncrushable objects. Features & Benefits • High output and excellent reduction capability • Heavy duty wear resistant hydraulic folding feed hopper with wedge fixing system • Excellent under crusher access for removal of wire with hydraulic raise lower product conveyor • Stepped self-cleaning grizzly feeder with under feeder screen option • Deep fines chute to reduce material blockages • Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber • Hydraulic crusher setting adjustment • Improved manganese liner retention, protects jaw supports on both swing & fixed jaws • Patented hydraulic crusher overload system, ideal for applications with un-crushable material in feed, 200mm3. Patent Publication Numbers: FR 1494810; DE 603 24 905.1-08; GB 2387342; US 7341213; CN ZL03810686.8 (Premiertrak R400) • Economical to operate with low fuel consumption due to highly efficient direct drive system • Angle adjustable product conveyor • Easy access powerunit canopy • PLC control system with auto start facility • Remote control via umbilical • Dust suppression system • Easily set up Options • Patented hydraulic deflector plate under crusher. Patent Publication Number: CN ZL03810686.8 • Side conveyor • Single pole/twin pole magnet • Radio remote control • Belt weigher • Electric refuelling pump • Hydraulically driven water pump • Wire mesh for underscreen • Super tooth or multi tooth jaw plates • Extended hopper Applications • Sand & gravel • Blasted rock • River rock • C & D waste • Overburden • Foundry waste • Processed ores • Processed minerals Output Potential: up to 400 tph (441 US tph)* Premiertrak R400 44,450kg (97,995lbs) including magnet & side conveyor Transport width Transport width Transport length Transport length Transport height Transport height Working width 2.8m (9’2”) 4.3m (14’1”) with side conveyor deployed Working width 2.8m (9’2”) 4.3m (14’1”) with side conveyor deployed Working length Working length Working height Working height

Open the catalog to page 1All Powerscreen catalogs and technical brochures

-

PREMIERTRAK 330

1 Pages

-

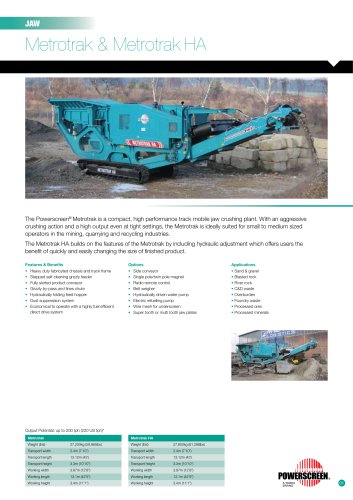

METROTRAK

2 Pages

-

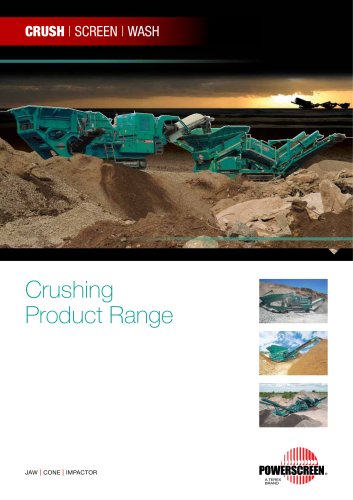

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

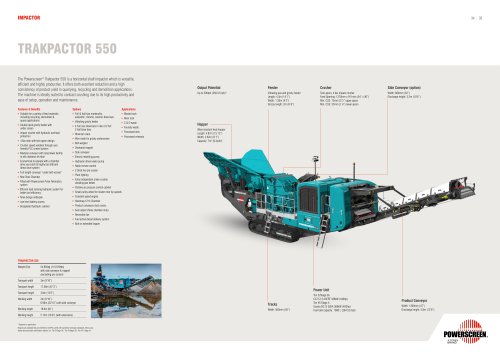

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

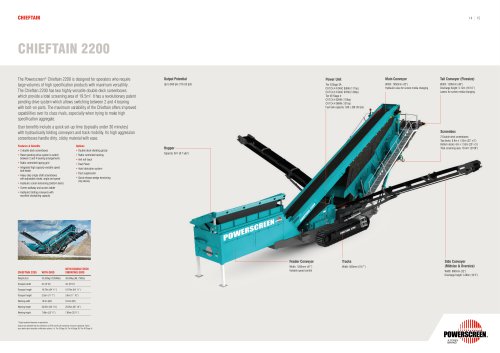

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

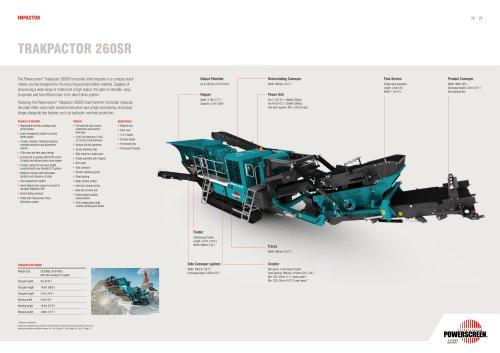

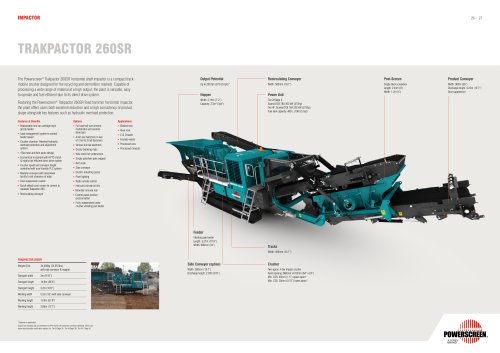

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

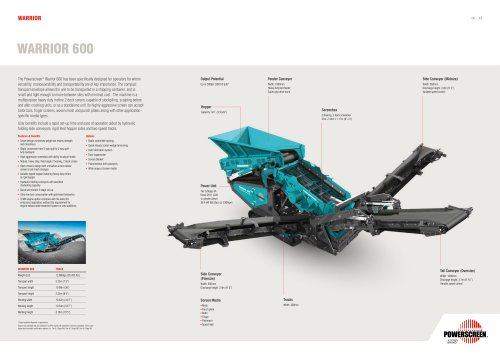

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XV350

1 Pages

-

XH250

1 Pages

-

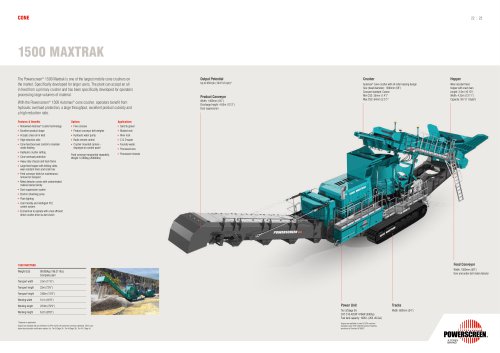

1500 Maxtrak

1 Pages

-

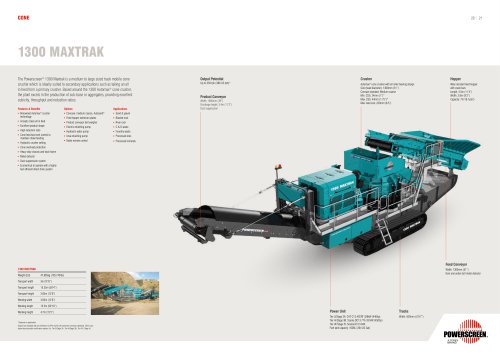

1300 Maxtrak

1 Pages

-

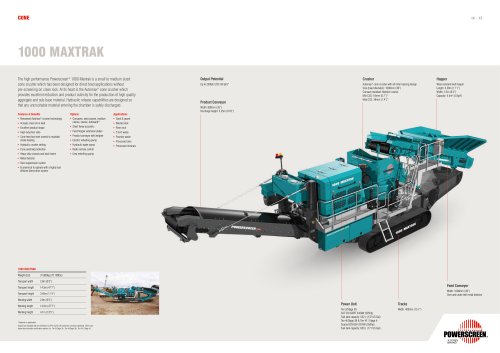

1000 Maxtrak & 1000SR

1 Pages

-

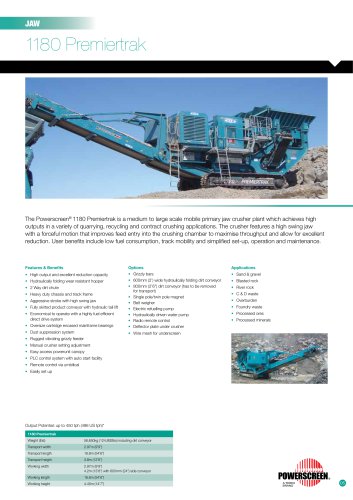

1180 Premiertrak

1 Pages

-

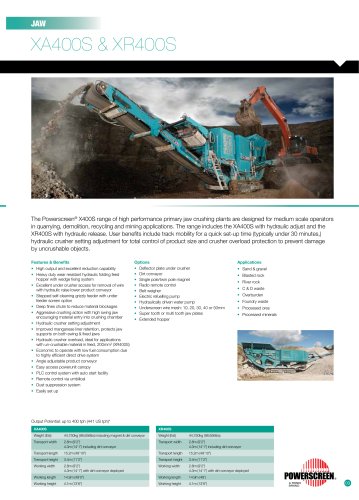

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

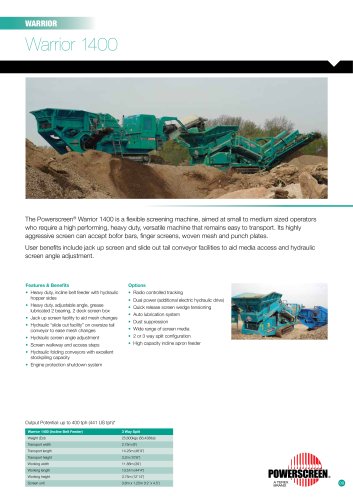

Warrior 1400

1 Pages

Archived catalogs

-

Powerscreen Mobile Crusher Range

16 Pages