Catalog excerpts

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:46 Page 1 Tracked Impactor & VSI Range | Quarrying > Contracting > Օ Recycling > Terex Pegson Ltd Mammoth Street, Coalville, Leicestershire, LE67 3GN, England. Tel: +44 (0) 1530 518 600 Fax: +44 (0) 1530 518 618 email: pegson.sales@terex.com www.terexpegson.com North America Office Terex Crushing and Screening Inc.11001 Electron Drive, Louisville, Kentucky, 40299 USA. Tel: +1 502 736 5200 Օ Fax: +1 502 736 5202 email: mail@terexcs.com FINANCIAL SERVICES The material in this document is for information only and is subject to change without notice.TerexPegson assumes no liability for errors or omissions in this document,or from the use of theinformation contained herein.We reserve the right to change specifications without notice due to continual product development.Product performance figures given in this brochure are for guidance purposes only.This informationdoes not constitute an expressed or implied warranty or guarantee,but shows test examples provided by dealers.These results will vary depending on feed material gradings,mesh sizes,feedsource and types of material being processed.Photographs are for illustrative purposes only.Some or all of the machines in the illustrations maybe fitted with optional extras.Please check with your dealer for details on optional extras.Terex is a registered trademark of Terex Corporation in the United States of America and many othercountries.Copyright Terex Corporation 2008. Published & Printed in August 2008. Your Local Authorised Terex Pegson Dealer: MODELS XH250428 TRAKPACTOR 4242SR 1412 TRAKPACTOR XV350 size="-1">

Open the catalog to page 1

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:47 Page 2 THE RIGHT CHOICE Choosing the right crusher for your application is an important decision. AtTerex Pegson we have the field experience and expertise to help you make the right choice. With over 75 years experience in crushing we will ensure your investment will work at its best for you throughout its service life.In todays market place businesses need to be armed with equipment thatcan be quickly adapted to suit different applications. At Terex Pegson we have risen to this challenge and produced a range of crushers that can achieve high...

Open the catalog to page 2

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:48 Page 3 The Terex > Pegson XH250 impactor is suitable for compact primary and secondaryapplications and with an overall weight of 26 tonnes / 28.7 US tons it is ideal for contract applications as it can be moved from site to site with ease. This plant is capable of processing all materialtypes and can achieve a throughput capacity up to 250tph / 275stph. Additional features include an overband magnet for the removal of rebar and a product conveyor that can be hydraulically raised/ lowered using the automated canbus PLC system. > Transport...

Open the catalog to page 3

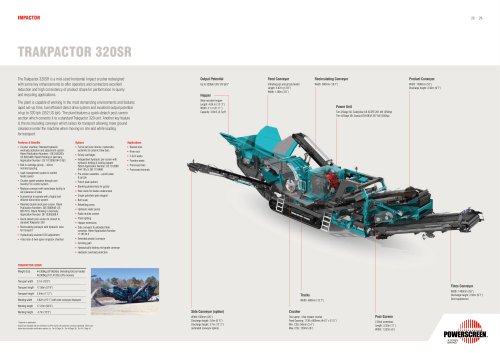

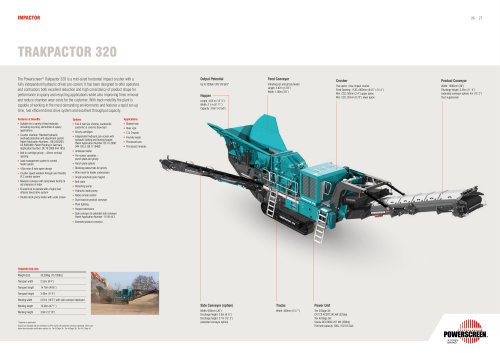

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:49 Page 5 The new 4242SR is based around the acclaimed 428 Trakpactor and comprises acomplete crushing, screening and stockpiling unit built on one tracked chassis.Suitable for primary and secondary applications in quarrying, contracting andrecycling, the 4242SR has outstanding performance characteristics, with capacities up to 360 tonnes / 400 stph per hour. Up to four product sizes, depending on the set-up, can be produced and stockpiled. Alternatively, oversize material can be re-circulated back to the crusher via an on-board conveyor to give a...

Open the catalog to page 5

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:49 Page 6 This impressive machine has been designed to work in quarry, demolition andcontracting environments and can achieve outputs up to 500tph / 555stph.A particular feature of this crusher is the hydraulic apron locking facility includingoverload protection. This provides consistent product size with less oversize than conventional spring loaded impact crushers as well as additional protection against tramp metal. It has also been designed so the crusher opens and adjusts automatically and is fitted with a hydraulic tilting feed plate to...

Open the catalog to page 6

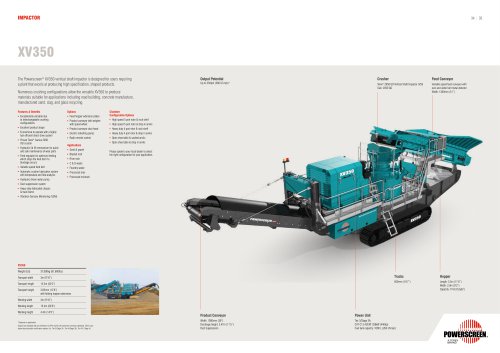

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:50 Page 7 The Terex > Pegson XV350 is fed by a 1.3m / 51Δ wide variable speed inclined feed beltwhich can be hydraulically raised and lowered for transport purposes. This new plant accepts a maximum feed size of up to 102mm / 4, producing a maximum throughput of up to 350 tonnes per hour - depending on the application. The throughput material from the VSI is fed onto a 1m wide product conveyor which has a 3.46m / 11Ԓ6 discharge height. The XV350 is controlled by a state-of-the-art touch screen control panel. For true site mobility, this new plant...

Open the catalog to page 7

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:51 Page 8 Material is gravity fed down a feed tube, where it hits the distribution plate. This fans the material out into thespinning rotor or table where it is picked up by shoes and accelerated outwards at very high speed, it then contacts either steel anvils or a rock shelf. This process induces impact and grinding of the material which results in excellent product shape and reduction. This machine is ideal for a number of shaping applications and excels at making chips, sand, concrete rock andsoft stone elimination. > VSI UNIT INCREASED ACCESS...

Open the catalog to page 8

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:52 Page 10 > Material Feed SizeProduct sizeThroughputTip Speed Hard Strength Rock-3/4" +3/4"-2"385stph134ft/sHard Strength Rock-2" +3/4"-1"350stph150ft/sHard Strength Rock-1" +3/8"-5/16"300stph184ft/s Medium Strength Rock-4" +3/4" -2"385stph134ft/sMedium Strength Rock-2"+3/4"-9/16"250stph174ft/sMedium Strength Rock-1 +3/8"-7/32"220stph200ft/sSlag-13/4" +5/8"-1"220stph200ft/sGlass25 fl oz Bottle-9/16"220stph184ft/s > ** Image shows a plan view of an Open Shoe Table Drop in Anvils (Heavy Duty Sand) Material Feed SizeProduct sizeThroughputTip Speed...

Open the catalog to page 10

IMPACTOR ENGLISH/USA (July 08) 26/8/08 17:54 Page 12 Terex > ή Pegson equipment is designed to operate in multi stage operations to providea complete crushing and screening train. AFTER SALES Our dealers are committed to supporting every aspect of your operation from supplyingproducts and parts to commissioning and servicing equipment. Their expertise will help you to improve productivity and lower operating costs throughout the working life of your machine. PARTS At Terex Pegson we know the right parts can make the difference to the efficiency and performance of your equipment so when you...

Open the catalog to page 12All Powerscreen catalogs and technical brochures

-

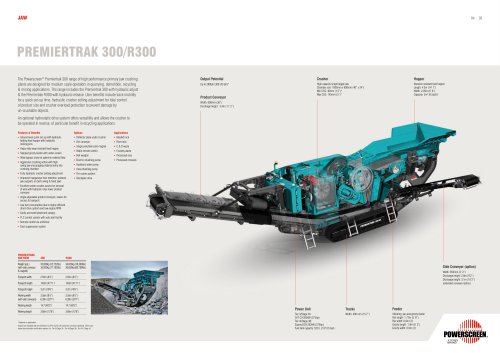

PREMIERTRAK 330

1 Pages

-

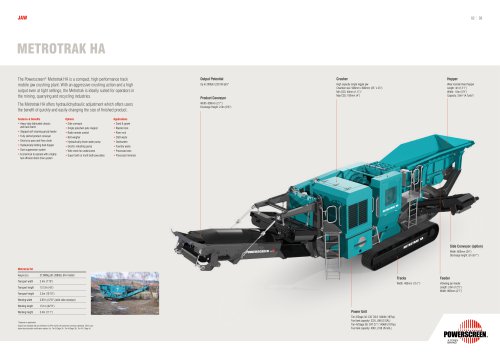

METROTRAK

2 Pages

-

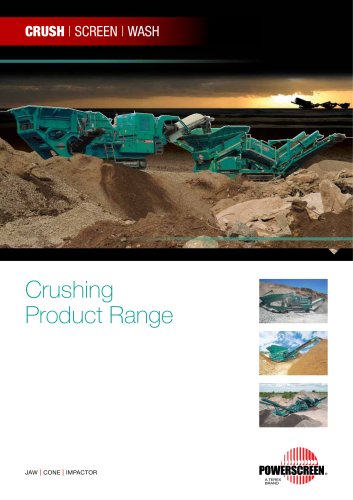

Crushing

25 Pages

-

Warrior 2100 Spaleck

1 Pages

-

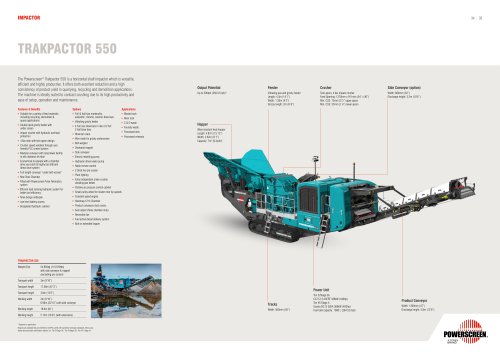

Trakpactor 550 Brochure

1 Pages

-

CHIEFTAIN 2200 3 DECK

1 Pages

-

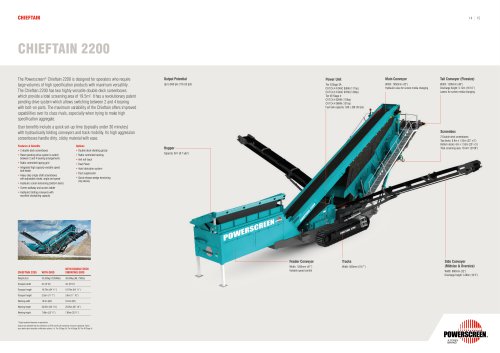

CHIEFTAIN 2200

1 Pages

-

TRAKPACTOR 500

1 Pages

-

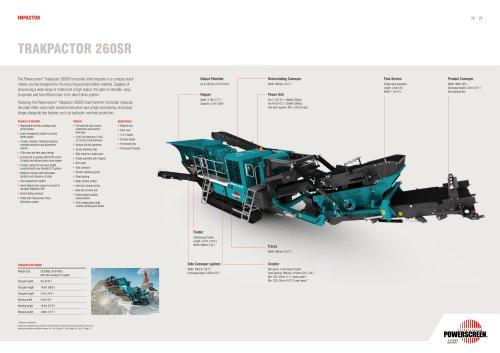

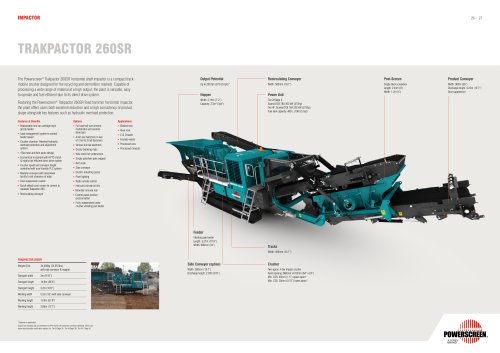

TRAKPACTOR 260SR

1 Pages

-

TRAKPACTOR 260

1 Pages

-

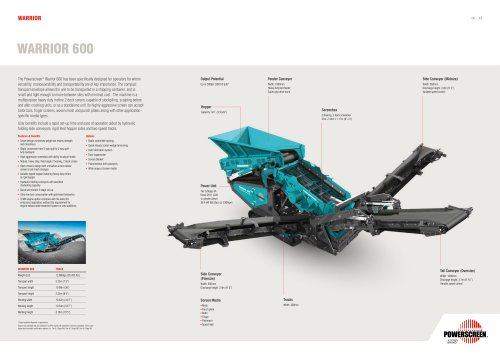

NEW Powerscreen Warrior 600

1 Pages

-

Warrior 2400

1 Pages

-

Warrior 1800

1 Pages

-

Warrior 1400X

1 Pages

-

Warrior 800

1 Pages

-

Chieftain 2100X BIVITEC

1 Pages

-

Chieftain 1400

1 Pages

-

XV350

1 Pages

-

XH250

1 Pages

-

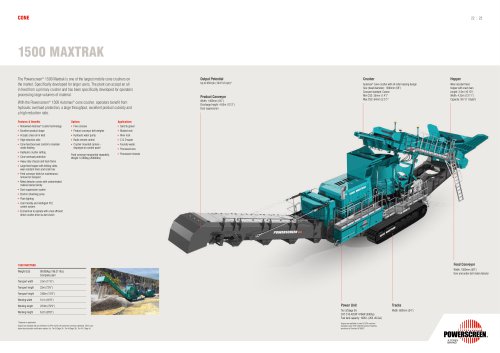

1500 Maxtrak

1 Pages

-

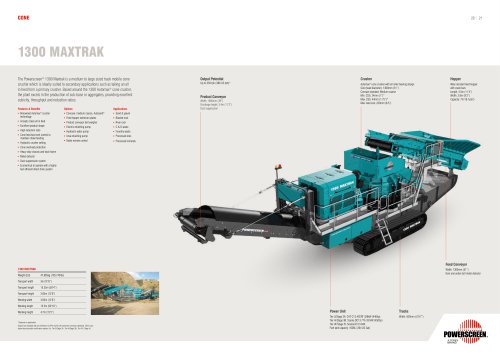

1300 Maxtrak

1 Pages

-

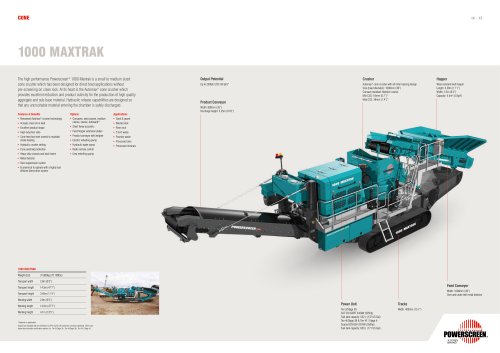

1000 Maxtrak & 1000SR

1 Pages

-

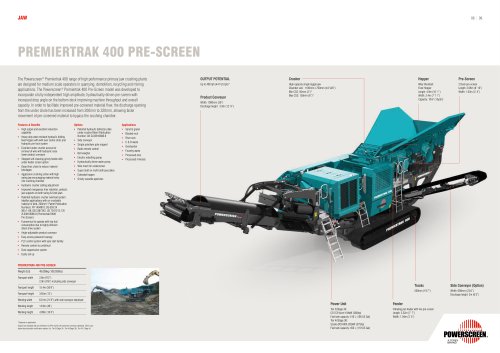

1180 Premiertrak

1 Pages

-

XA400S & XR400S

1 Pages

-

Powerscreen® Aggwash

1 Pages

-

Warrior 1400

1 Pages

Archived catalogs

-

Powerscreen Mobile Crusher Range

16 Pages