Catalog excerpts

PRINA EXTRACTION PROCESS Prina Hopper Preliminary Prina Preparation Malaxator and Sieve Olive Seed Separator Prina Pump Storied Malaxator with Overflowing System Decanter Separator

Open the catalog to page 1

Prina Hopper Capacity: 10 tons Material: St-37 Engine Power: 10 Kw This is the first stop for the prina, which is brought to the facility for extraction. Prina is delivered to the next preliminary prina preparation malaxator with the spirals existing in the hopper, which is filled with the help of a scoop.

Open the catalog to page 2

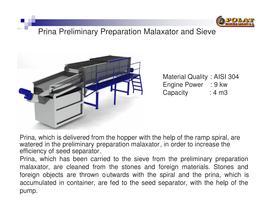

Prina Preliminary Preparation Malaxator and Sieve Material Quality : AISI 304 Engine Power : 9 kw Capacity : 4 m3 Prina, which is delivered from the hopper with the help of the ramp spiral, are watered in the preliminary preparation malaxator, in order to increase the efficiency of seed separator. Prina, which has been carried to the sieve from the preliminary preparation malaxator, are cleaned from the stones and foreign materials. Stones and foreign objects are thrown o utwards with the spiral and the prina, which is accumulated in container, are fed to the seed separator, with the help...

Open the catalog to page 3

Prina Pump Material Quality : AISI 304 Engine Power : 5,5 kw : 10 tons/hour Capacity It provides delivery of the p rina to the desired unit. It has vacuuming feature. Within the vacuum pump, which has a compact structure from the appearance and usage aspects, all of the surfaces, with which the product has contacts, are manufactured from AISI 304 quality inox materials in compliance with food codex .

Open the catalog to page 4

Seed Separator Chassis Material: St 37 Engine Power: 30 KW Capacity: 7 tons/hour Seed separator is designed to separate the seeds from the other pulp contents within the prina. Prina is taken into the drum by the cover through the spiral. Prina is then given between a four plated shaft and sieve , and from there, seeds and pulp content are separated, as the seeds inside the prina are being proceeded over the sieve, while the pulp content passes through the sieve. Seeds are discharged from the front section.

Open the catalog to page 5

Storied Malaxator with Overflowing System Material Quality : AISI 304 Engine Power : 22,5 kw Capacity : 12 m3 Prina extraction malaxator consists of 3 separate sections, which are independent from each other. E ach one of these sections has a volume of 4 m3. All of the surfaces, with which the prina has contacts, and all of the hot water contact surfaces are manufactured of AISI 304 quality stainless steel. With the mixers having special designs and PLC control systems, it provides high efficiency. With the help of the PLC control system, all of these sections are equipped and supported...

Open the catalog to page 6

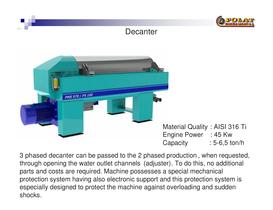

Decanter Material Quality : AISI 316 Ti Engine Power : 45 Kw : 5-6,5 ton/h Capacity 3 phased decanter can be passed to the 2 phased production , when requested, through opening the water outlet channels (adjuster). To do this, no additional parts and costs are required. Machine possesses a special mechanical protection system having also electronic support and this protection system is especially designed to protect the machine against overloading and sudden shocks.

Open the catalog to page 7

Seperatör Material Quality: DIN 1.4462 (Duplex) Engine Power : 11 kw : 3000-3500 l/h Capacity PMS 505 Centrifuge separators make it possible to process the big amount of oils, with help of the semi-automatic shocking system. The perfect operation selection for the machine’s centrifuge unit is a product of POLAT Technology. The advanced technology manufactured by POLAT MACHINERY and correct material selection and fault -free installation guarantee the perfect operation of the machine.

Open the catalog to page 8

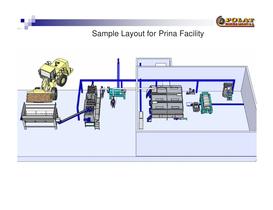

Sample Layout for Prina Facility

Open the catalog to page 9All POLAT MAKINA SANAYI VE TICARET A.S. catalogs and technical brochures

-

Kern Separator PMS PS 7000

1 Pages

-

Kern Separator PMS PS 5000

1 Pages

-

PMS 350 PX 20

20 Pages

-

470-70

20 Pages

-

px70

20 Pages

-

px40

20 Pages

-

px20

20 Pages