Catalog excerpts

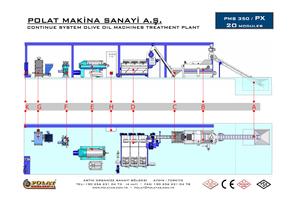

POLAT MAKİNA SANAYİ A.Ş. PMS 350 / 20 MODULER CONTINUE SYSTEM OLIVE OIL MACHINES TREATMENT PLANT K G F E H D C ASTİM ORGANİZE SANAYİ BÖLGESİ AYDIN / TÜRKİYE TEL: +90 256 231 04 73 (4 hat) * FAX: +90 256 231 04 78 www.polatas.com.tr * polat@polatas.com.tr PX B A

Open the catalog to page 1

THE FUNCTIONS OF OLIVE OIL MACHINES WITH PMS 350 / PX 20 MODULER SYSTEM A. OLIVE CARRYING MACHINE A1. CONVEYOR Olive carrying line A2. LEAF ASPIRATOR Leaf,grass….etc.seperating unit B. OLIVE WASHING MACHINE Olive washing and Stone ,sil,…etc.seperating unit C. FEEDING SCREW CONVEYOR Olive feeding unit for the crasher D. PASTE PREPARE UNIT D1. CRASHER Olive crashing unit D2. MODULER MIXER E. DECANTER E1. DECANTER Olive extraction unit E2. VIBRATION SIEVE E3. PASTE PUMP E4. OIL PUMP F. SEPERATOR Oil,water,paste seperation unit G. WATER HEATHER AND HEATH EXCHANGER G1. AUTOMATIC HEATH EXCHANGER...

Open the catalog to page 2

CAPACITY AND POWER CONCUMPTION OF THE OLIVE OIL MACHINE OF PMS 350 / PX 20 CONTINUE SYSTEM OLIVE CARRYING LINE CARRYING CAPACITY TOTAL ENGINE POWER : 2 TONS/HOUR : 2.25 KW OLIVE WASHING MACHINE WASHIN CAPACITY TOTAL ENGINE POWER : 2 TONS/HOUR : 1.585 KW FEEDING SCREW CAPACITY TOTAL ENGINE POWER : 2 TONS/HOUR : 0.75 KW BREAKER CAPACITY TOTAL ENGINE POWER : 1.5 TONS/HOUR : 11.37 KW MODULAR MIXER CAPACITY TOTAL ENGINE POWER : 1.2-1.8 TONS/HOUR : 6.6 KW PASTE PUMP PMS 65 CAPACITY TOTAL ENGINE POWER : 1.5 TONS/HOUR : 0.75 KW DECANTER CAPACITY TOTAL ENGINE POWER : 20 TONS/DAY : 11.32 KW HUSK...

Open the catalog to page 3

A. CONVEYOR WITH OLIVE CARRYING LINE A1.CONVEYOR 1000mmx1000mm olive bunker is produced by inox material AISI 304. The conveyer is designed from plate materials of AISI 304 without spools so that it does not require extra maintenance. The tightening system of the band conveyer is carried out with a screw for tightening, the line is tightened from the back part of drum. The line is driven coupled from front drum by a reducer and engine. The fixing place for the reducer-engine group can be on the right or left side of the conveyer according to the assembly in the building. The band is 250mm...

Open the catalog to page 4

A2. LEAF ASPIRATOR Aspirator is fixed to the front part of the conveyer optionally.it is produced in order to seperate the light materials such as leaf, grass, ...etc. from the olive. The wings providing the air circulation of the aspirator are made of stainless steel AISI 304 quality and the outer part of it is manufactured out of AISI 304 material. There is a lid at the side of the body permitting to clean inside of the aspirator easily. Transfer number Engine power Capacity (leaf) Weight : : : : 3000 rpm 1,5 kw 1000 m3/min. 38 kg Note : dimensions are cm. 2

Open the catalog to page 5

B. OLIVE WASHING MACHINE All surfaces that olive is touched and washed and all parts in water storing chambers are produced from inox material AISI 304 in quality. The particles within the olive sink to the bottom of the special designed chamber where olive flows. The heavy meterials ( stone, metal,...etc.) collected are evacuated after the machine stops by a manually driven spire. The olive passes the washing chamber and comes to frontal vibrated sieve . Here the olive leaves the water and falls into the feeding screw bunker. The system is designed in a way which provides continuous...

Open the catalog to page 6

C. OLIVE FEEDING SCREW CONVEYOR All surfaces the olive touches along the transport to the crashing machine are manufactured from inox AISI 304 material in quality. Conveyer screw wings are produced out of inox material of AISI 304 quality in order to strengthen against the abrasion occured during time.Conveyor motion is realized by reducer from the front side of spiral body. Quality of all material used Rustproof pipe thickness Screw elevator thickness Banker plate thickness Screw diameter Screw length The type of the reducer Reduction ratio Engine power Engine transfer Capacity Weight : :...

Open the catalog to page 7

D. PASTE PREPARE UNIT D1. CRASHING MACHINE It is the unit where olives are crashed. With turning hammer system and special tearing blades, it enables quality oil production without heat formation.The entrance parts through which the olives to be broken and enter the unit and the front breaking lid are produced out of inox material AISI 304 in quality. Crashing hammers 2080 special material, for the main body are designed out of AISI 304 material. The sieve plate where the olive paste is collected is produced from the inox material AISI 304 inox in quality. The olives carried to the crashing...

Open the catalog to page 8

D2. MODULER MIXER The modular malaxer consists of 3 sections independent from each other. Each section has a volume of 0,45m3.All surfaces olive paste contacts and exterior surfaces are made of AISI 304 stainless steel. It has got higher productivity with the aid of PLC control system, observation Lid,Washing installation, adjustable water flowrate equipment and specially designed mixers. With the help of PLC control system, each section is supported with charge, discharge and level switches. With the assistance of this system, operator mistakes and mixing customer products becomes...

Open the catalog to page 9

E. DECANTER E1. DECANTER The Engine ,driven by Inverter, increases the drummer rotation to the 3800 r/m .This creates the centrifugal forces which keep the oil production at the maximum level . Thus, the system enables to seperate the crude paste, water and the olive oil from each other as per their specific gravity.The paste carried by the paste pump enters the decanter drum together with the water coming from the flowmetre at 35-45 C. The water is transferred to the lower chamber of the decanter from the entrance channel behind the drum and then it is sent to the vibrated sieve near the...

Open the catalog to page 10

DECANTER PERFORMANCE GUARANTEE FOR 3 PHASE; Daily olive processing capacity 20 TON / DAY MAX OİL İN HUSK. % 3-4 (% 50 HUMİDİTY) MAX OİL İN DİRTY WATER % 0.5 gr / lt FOR 2 PHASE; Daily olive processing capacity 20 TON / DAY MAX OİL İN HUSK. % 1-2 (% 60 HUMİDİTY) Note : dimensions are cm. 8

Open the catalog to page 11

E2. VİBRATION SIEVE All materials used are manufactured from AISI 304 inox in quality in accordance with the good regulations since they touch directly to oil and water. It consists of two parts. These are as follows: The sieve which holds the deposits within the oil and the other part consists of two units in which water and oil are collected and transmitted. The deposits within the water coming in to the sieve are held by specially designed sieve plate. The water here goes to the lower unit and it is discharged out of the system through the entrance channel. Like the water the oil also...

Open the catalog to page 12All POLAT MAKINA SANAYI VE TICARET A.S. catalogs and technical brochures

-

prina-extraction

9 Pages

-

Kern Separator PMS PS 7000

1 Pages

-

Kern Separator PMS PS 5000

1 Pages

-

470-70

20 Pages

-

px70

20 Pages

-

px40

20 Pages

-

px20

20 Pages