Catalog excerpts

PRODUCT CATALOGUE LINEAR BEARINGS AND SLIDES

Open the catalog to page 1

Company's headquarters in Dedemsvaart, Netherlands INTRODUCTION PM has engineered and manufactured innovative and top quality precision linear bearings and slides at our research and production facilities in the Netherlands since 1966. We are experts in finding solutions that meet the specific requirements of a wide variety of industry applications. A trusted partner for hundreds of industry heavyweights around the globe, our client base ranges from the semiconductor industry, medical technology and metrology sectors, to industrial automation, space and defence industries. Innovative design...

Open the catalog to page 2

INDEX PART I: LINEAR BEARINGS 3 INTRODUCTION 7 PRODUCT OVERVIEW LINEAR BEARINGS General, friction, lubrication, materials, cages, characteristics of cages, cages for RSD and DS rails, cages for RSDE and RNG rails, operating temperature, temperature, packaging, ceramic linear bearings, hign vacuum and UHV application 11 EXPECTED LIFETIME Load ratings and expected lifetime, fatigue, short stroke, nominal operational calculation life (L10), temperature factor FT, hardness factor FH, dynamic and static load ratings, static safety factor 14 DESIGN INFORMATION Accuracy grades,...

Open the catalog to page 3

PRODUCT OVERVIEW Importantly, PM customers benefit from over 50 years’ experience in the field of linear bearings manufacturing. As a result of our continuous testing of innovations and new insights in engineering and manufacturing, our linear bearings are constantly being optimised further and often become an industry benchmark. PM linear bearings are used as components in multiple industries worldwide. What really sets apart PM products is their unsurpassed quality and technical performance in terms of accuracy, their extremely low levels of friction, high rigidity and long lifetime. Our...

Open the catalog to page 4

GENERAL PM linear bearings and frictionless precision slides are available in various models with ball and roller diameters available in many standard lengths and sizes. The range of sizes and lengths covers virtually all industry applications and allows the designer to solve most problems in the field of linear movement when it comes to frictionless movement with adjustable preloads. Additionally, PM linear bearings are virtually free of wear and require little lubrication or maintenance (specific conditions of use need to be considered for every application). Application fields include: •...

Open the catalog to page 5

EXPECTED LIFETIME for high accelerations and high operating temperatures. For overrunning cages purposes please consult a PM advisor. OPERATING TEMPERATURE PM linear bearings are capable of operating in temperature of +120 °C. For linear bearings with plastic components, the operating temperature range is -30 °C to 80 °C. In case of any doubt or when using motors, ball screws, measuring systems, etc., please contact us. For any enquiries about applications that are to operate beyond this temperature range, please consult a PM advisor. TEMPERATURE Operating environments that have temperature...

Open the catalog to page 6

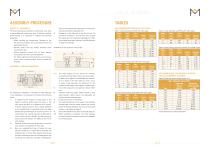

TEMPERATURE FACTOR Ft Diminished rail hardness will start to occur in PM linear bearings when deployed at temperatures over 150 °C. As a result, load ratings must be reduced with a factor Ft as shown in the table below. This applies to the reduction of the dynamic load rating Cdyn and the static load rating C0. STATIC SAFETY FACTOR The static safety factor S0 determines the degree of safety against permanent deformation of the contact surfaces of the rails and rolling elements. The safety factor represents are relationship between the basic static load rating C0 and the equivalent maximum...

Open the catalog to page 7

DESIGN INFORMATION If accuracy grade Q4 or Q2 is required for your order, please add a suffix "Q4" or"Q2" to the rail type number (for example: RSD-6300-Q4). Higher accuracies can be supplied on request. If applicable, please consult your PM advisor. ACCURACY GRADES The linear bearings manufactured by PM come in three grades of quality. The quality grade refers to the degree of parallellism between the running surfaces and reference surfaces A and B of the rail, as illustrated in graph and figure below. Parallelism accuracy grades 9 ‘ ■ <1 7 o 6 ■o 5 4 2 3 E Q8: Standard precision grade,...

Open the catalog to page 8

As regards cage length and the associated load capacity, PM recommends a stroke length (H) of 70% of the (longest) rail length (A). In case the rail length is longer than 400 mm the stroke length can be increased up to a maximum of 100%. H/A < 0.7 (for H < 400 mm) H/A < 1 (for H > 400 mm) TOLERANCES OF MOUNTING SURFACE For standard applications an average mounting surface roughness of Ra 1.6 must be observed. For quality classes Q4 and Q2 the mounting surface roughness values are Ra 0.8 and 0.2. To achieve precision of the system the rails must be pushed against the mounting surface and...

Open the catalog to page 9

ASSEMBLY INSTRUCTIONS One set of linear bearings consists of 4 pcs. rails (2 pairs), 2 pcs. cages and 8 pcs. end screws or end pieces. STANDARD FITTING EXAMPLES Our range of linear bearing components can be positioned in any spatial orientation or direction required for your application. Rails can be attached to the slide base construction either using the threaded holes or using the through holes. Use of RSD, RSDE or RNG PRELOAD SETTINGS In order to assure a play-free movement and to increase the stiffness and accuracy of the linear bearing, preload adjustment is necessary. To adjust the...

Open the catalog to page 10

ASSEMBLY PROCEDURE PRIOR TO ASSEMBLY PM linear bearings are precision components; they have to be handled with meticulous care. To achieve a perfect linear bearing, it is necessary to respect the following guidelines: • When handling the components. Damage on the rail surface will impact the running performance and operational lifetime • Prevent contact with any foreign materials when mounting the rails • During assembly, ensure that all linear bearing components have the same temperature • For uniform tightening of the bolts the use of a torque screw driver is recommended. Various models...

Open the catalog to page 11All PM B.V. catalogs and technical brochures

-

LINEAR BEARINGS TYPE RNG

8 Pages

-

Frictionless slides type RT

11 Pages

-

LINEAR BEARINGS TYPE N/O

13 Pages

-

PRODUCT OVERVIEW

5 Pages