Catalog excerpts

Let's add value to milk 1-3-2017-ANG

Open the catalog to page 1

PLEVNIK company Tradition • More than 25 years of experience in milk and cheese equipment • More than 250 cheese kettles and batch milk pasteurizers produced every year • More than 1500 cheese kettles and batch milk pasteurizers currently in daily use all over the world • Our satisfied customers are located in all biggest European cheese making markets (France, Italy, Switzerland, Austria, Germany, Great Britain, Spain, Czech republic, Slovakia, Sweden...) as well as other markets all over the world (Russia, Canada, Mexico, Peru, Japan, South Corea, Malaysia, Australia, New Zeland,...

Open the catalog to page 2

Plevnik products - • Pasteurizer PH is a universal device used for the milk pasteurization and its thermal reproduction into dairy products such as yogurt, pasteurized milk, cheese, curd, cream... . It can be used as a pasteurizer, cheese kettle, milk cooling tank and fermenter in the same production process or only one of these funcions can be used as stand-alone production process. • Pasteurizer PH allows the thermal treatment of milk in a temperature range between 4°C and 100°C. - Heating is done by: electrical heaters or electrical heaters in combination with a heat pump (option: other...

Open the catalog to page 3

• All-in-one compact execution • Easy to use and very reliable • Minimal size • User friendly touch screen controller capable of saving up to 10 different programs • Economical operation • Does not need an outside energy source of heating (hot water, steam, gas...) or cooling (water, iced water...) • All it needs is an electrical connection 400V 3N 50Hz (other voltages and frequencies available on request) • Milk is cooled by a cooling aggregate that cools down to 4°C • The kettle has a three part insulated energy - saving construction (closed circuit heating and cooling system) made...

Open the catalog to page 4

• Easy to use and very reliable • User friendly touch screen controller capable of saving up to 10 different programs • Economical operation • Does not need an outside energy source of heating (hot water, steam, gas...) or cooling (water, iced water...) • All it needs is an electrical connection 400V 3N 50Hz (other voltages and frequencies available on request) • Milk is cooled by a cooling aggregate that cools down to 4°C • The kettle has a three part insulated energy - saving construction (closed circuit heating and cooling system) made entirely of stainless steel W.Nr.1.4301 • Thermal...

Open the catalog to page 5

included parts and main optional equipment for the pasteurizers Type:_ Heating up to: Cooling down to: Material - stainless steel: Energy saving construction of the kettle (laser welded) 2R polished interior of the kettle (mirror) Outflow DN 50 Outflow DN 65 Water circulation pump (reduces energy consumption) One part cover, standard propeller stirrer 23 rpm Console for the stirrer, two part cover Stirrer 75% diameter of the kettle Dispersion stirrer Scrape stirrer Stable suport with inclination mechanism Support on wheels Working platform Elevating device Inox protection around the support...

Open the catalog to page 6

Additional equipment - Accessories • A wide range of accessories are available as well. They can extend the usefulness of the device, extend variety of dairy products and increase production efficiency. • Available are different types of stirrers, supports, temperature recorders, stirrer speed control, elevating device, curd draining strip, ... Elevating device Special stirrer for yogurt Working platform Movable console of the stirrer, two part cover Stainless steel cover of the installation under the kettle Scrape stirrer Three-part cheese harps Digital temperature recorder Application...

Open the catalog to page 7

ADVANTAGES OF THE PH MACHINES: SIMPLE INSTALLATION • Minimal installation requests = Minimal installation costs EASY TO USE • User friendly touch screen controller able to save up to 10 different programs (all process parameters can be changed, monitored and saved within controller/ process operation, fast and simple stirring replacement) THERMAL TREATMENT • Thermal treatment of milk in the range of 4°C to 100°C QUALITY MANUFACTURING • Best performance / size ratio on the market - minimal size and maximal performance • Extended lifetime - of the device, due to laser welded coat made of high...

Open the catalog to page 8All Plevnik D.O.O. Engineering and production catalogs and technical brochures

-

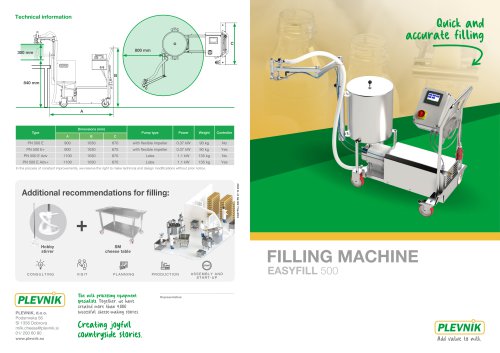

EASYFILL 500

2 Pages

-

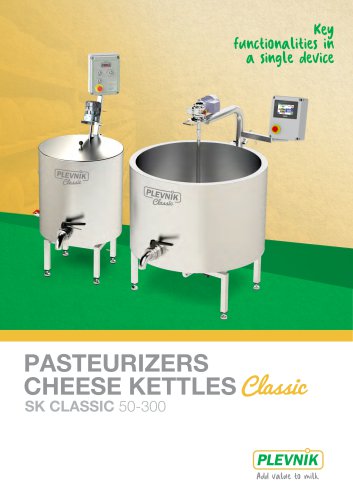

SK CLASSIC 50-300

6 Pages

-

TO PRODUCT

36 Pages

-

Pasteurizers P 50 - 1000

6 Pages