Catalog excerpts

Short Catalog Standard coating units

Open the catalog to page 1

PLATIT Short Catalog About us 4 Sales partners & agents 50

Open the catalog to page 3

PLATIT is a leading manufacturer of high-tech PVD and PECVD coating units for tools and machine components. The company is part of the family-owned BCI Blösch Group, an independent Swiss technology group. PLATIT is headquartered in Selzach (Switzerland) and has its own service, support and sales offices in Europe, North America and Asia. These are complemented by a broad network of distributors and partners worldwide. PLATIT has installed over 550 coating systems and maintains close partnerships with its customers. The variety of tool geometries and applications requires manufacturers of...

Open the catalog to page 4

Global presence o PLATIT Shanghai Sales, Service, CEC Shanghai, CN o PLATITAG Custom Coating Solutions [CCS] Vaulruz, CH PLATIT has installed coating systems for customers in 39 countries around the world.

Open the catalog to page 5

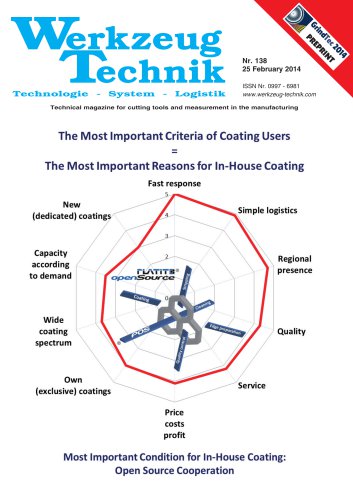

About us What we stand for Open Source Customer Partner ship Integration Flexibility Core competencies of PLATIT are integration, flexibility, open source and strong customer relationships. Integration enables in-house coating. Thanks to our comprehensive understanding of the manufacturing as well as the regrinding of tools, we develop optimized solutions for our customers, which we seamlessly integrate into their existing production process. Flexibility refers to our business model and our products. Our PVD standard coating units are based on a modular design. With different implemented...

Open the catalog to page 6

Coating units PLATIT Coating Intelligence

Open the catalog to page 7

Standard cdating units & custom cdating sdlutidns PLATIT offers high-tech PVD and PECVD coating units. Depending on the requirements, we equip them with the following technologies: • ARC in DC or pulsed mode • SPUTTER in DC, pulsed or HiPIMS mode • Hybrid technology with simultaneous ARC & SPUTTER processes The focus of PLATIT is on the tool and machine component field, but we also manufacture tailor-made Custom Coating Solutions for special requirements. Load and cycle times of shank tools 288 pcs., 504 pcs., ARC technology 2 x LARC® PLUS cathodes 3 x LARC® cathodes, upgradable with 1 x...

Open the catalog to page 8

PVD standard coating units PVD standard coating units from PLATIT are perfectly suited for coating tools and machine components with standard market sizes. They enable short cycle times with high-quality coatings and can be flexibly programmed with different coating structures. Standard coating units can deposit PVD and PECVD for various nitride, oxide and DLC coatings. with CrN - 4 x Planar cathodes 3 x LARC® XL cathodes, 2 x Planar cathodes 2 x Planar cathodes - -

Open the catalog to page 9

Smart Speed Unit PLATIT Coating Intelligence

Open the catalog to page 11

111 Smart Speed Unit Arc Technology – 2 rotating cathodes A LARC® PLUS cathode B LARC® PLUS cathode C Carousel Pi111 PLUS G3 represents the third generation of a compact PVD c oating unit from PLATIT. Its key features are fast cycle times, easy operation and user-friendliness at a favorable price – without compromising coating performance. Having two rotating cathodes utilizing ARC technology, the unit deposits selected PLATIT Signature Coatings at a consistently high level of quality. It is the ideal choice for customers looking to enter the coating world or wanting to add a fast, low...

Open the catalog to page 12

Technologies applied: 2 x LARC® PLUS (LAteral Rotating PLUS Cathode] for ARC deposition Advantages of LARC® PLUS compared to LARC®: • Improved target utilization (up to 30%] • Enhanced magnetic field system and thus increased deposition rate • Quick cathode exchange

Open the catalog to page 13

Etching technologies applied: • LGD® (Lateral Glow Discharge] • Plasma etching with argon, glow discharge • Metal ion etching (Ti, Cr] Load and cycle times: • Max. coating volume: 0 353 x H 498 [mm] • Max. coating height with defined coating thickness: 414 mm • Max. load: 160 kg 4-5 batches/day for12: Shank tools (2 pm]: 0 10 x 70 [mm] 288 pcs. 4.5 h * Average cycle times for a typical coating mix in a production environment. Modular carousel systems: • Dual rotation kicker carousel or triple rotation gearbox system Software: • Simple use and maintenance • PLATIT's SmartSoftware (PC and PLC...

Open the catalog to page 14

Ultra Flexible Unit PLATIT Coating Intelligence

Open the catalog to page 15

411 Ultra Flexible Unit The concept of the rotating central cathode The broad variety of configuration options as well as the flexibility made possible by the rotating cathodes, enables the development of customer-specific coatings with the highest performance. Thus, this coating unit addresses customers who are seeking maximum flexibility with full range of coating technologies easily accessible in one machine. LARC® cathode LARC® cathode LARC® cathode CERC®/ SCIL® cathode Carousel Due to its modular design and the range of available technologies, Pi411 PLUS is the world’s most flexible...

Open the catalog to page 16

Technologies applied: ECO: Basic configuration with 3 x LARC® (LAteral Rotating Cathode) inside the door for ARC deposition DLC2 (PECVD): For a-C:H:X respectively a-C:H:Si coatings TURBO: ECO + CERC® (Central Rotating Cathode) with ARC technology to increase productivity and enable most complex coatings OXI: For oxide coatings in corundum structure SCIL® (SPUTTERED Coating Induced by Lateral Glow Discharge): High performance SPUTTERING from the central cathode Hybrid LACS®: Simultaneous ARC & SPUTTER processes with LARC® inside the door and central SCIL® cathode Hybrid LACS® Solution Turnkey

Open the catalog to page 17

Etching technologies applied: • LGD® (Lateral Glow Discharge] • Plasma etching with argon, glow discharge • Metal ion etching (Ti, Cr] Load and cycle times: • Max. coating volume: 0 540 x H 500 [mm] • Max. coating height with defined coating thickness: 414 mm • Max. load: 200 kg Up to 5 batches/day for12: Shank tools (2 pm]: 0 10 x 70 [mm] 504 pcs. 4.5 h * Average cycle times for a typical coating mix in a production environment. Modular carousel systems: • 1 to 14 axes Software: • Simple use and maintenance • PLATIT's SmartSoftware (PC and PLC system] • Modern control system with touch...

Open the catalog to page 20All PLATIT AG catalogs and technical brochures

-

Compendium

140 Pages

-

CCS Custom Coating Solutions

12 Pages

-

Hybrid Coating

4 Pages

-

PLATIT’s new DLC coatings

2 Pages

-

Complete Solutions in Demand

6 Pages

-

Productive Decoating

4 Pages

-

Coatings with Boron

4 Pages

-

Dedicated Coating Systems

5 Pages

-

My Tool, My Coating

6 Pages

-

New Quad Coatings

8 Pages

-

Coating of Large Chunks

4 Pages