Catalog excerpts

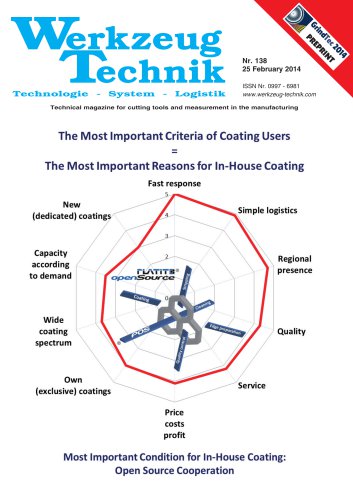

Technical magazine for cutting tools and measurement in the manufacturing

Open the catalog to page 1

Fig. i : From «rtr to LACS® -The options of the new coating unit HYBRID LACS' Hybrid option for simultaneous ARCing and sputtering . High performance i sputtering i ' for smooth ' surfaces / Option for oxide coatings with high chemical and thermal isolation The highest dangers for the big corporations (you must not necessarily think of the Apples and Googles) come from two different directions: - From the central administrations (governments, EU, IRS, OECD, etc.), which pay attention to tax breaks, data protection and monopoly proceedings, as well as - From the small, innovative start-ups...

Open the catalog to page 2

Fig. 3: Typical Coatings of the Options of the 7[****tt". - The OXI option builds on the configuration It was developed pri marily for SMEs, which cannot afford CVD plants and which want to deposit oxide films themselves in small series. - With the SCiL® option (Sputtered Coating induced by Lateral Glow Discharge), a sputtering cathode is placed into the central position, which allows a high deposition rate for smooth high-perfomance layers [3]. The technology blows on attacking the conventional, but still so often used, ionitron (eBeam) coatings. - The LACS® option (LAteral Arcing &...

Open the catalog to page 3

Cutting Performance at Milling [min//um) Mat.: Tool steel -1.2085 - X33CrS16 - HRC 29.2 - a,=5 mm - a,=02.5 mm - v,=120 m/min Tools: d=8 mm - Fraisa NX-V Torus - d=2.2 mm -2=4- f,=0.06 mm/tooth -MQL Average wear = (Max. margin wear + VBmax (clearence wear) + Top edge wear + corner wear) / 4 CrTi, etc.). They are used to deposit the LACS® versions of the conventional layers, such as AlTiN-LACS®, AlCrN-LACS®, CrTiN-LACS®. They have ARC qualities with fewer droplets. However, they can also be constructed from thermally poorly conductive materials (e.g., B4C, TiB2, SiC, W). This type of...

Open the catalog to page 4

Mat.: Heat treated steel —1.7225 — 42CrMo4 - HRC 30-a,= 18 mm - vt=120 m/min Tools: Solid carbide drill -d=6.8 mm - Schlenker GmbH -z=2 — f=0.15 mm/rev-MQL Measured at GFE. Schmalkalden, Germany [1], and thus achieves a higher tool life than the TiCN, produced by the ioni-tron process (Fig. 4) - Due to the good avoidance of built up edges, TiB2 is the classic layer for aluminum machining. What is the goal of the LACS® option with the simultaneous combination of ARCing and sputtering? Of course, the using of their advantages: •ARCing: perfect layer-adhesion, -density, -hardness, -structure...

Open the catalog to page 5

I L^\l I I Advanced Coating Systems SWISS £? OUAIITY www.platit.com s: NEvV Coating Unit ji^11PLLJSModular and Flexible in Structure and Applications JJ-&Z7TURBO High productivity using a CERC booster Option for oxide coatings (nACoX") with high chemical and thermal isolation Option with PECVD; technology for lubrication-coatings Hardware Options High performance sputtering for smooth surfaces HYBRID LACS® JlU11 The base machine for easy start up Hybrid Option for simultaneous ARCing and sputtering AlCrN: Nanosphere'' for hobbing AlCrN-LACS® BorAC®=AICrN/BN for milling with low internal...

Open the catalog to page 6All PLATIT AG catalogs and technical brochures

-

Short Catalog

52 Pages

-

Compendium

140 Pages

-

CCS Custom Coating Solutions

12 Pages

-

Hybrid Coating

4 Pages

-

PLATIT’s new DLC coatings

2 Pages

-

Complete Solutions in Demand

6 Pages

-

Productive Decoating

4 Pages

-

Coatings with Boron

4 Pages

-

Dedicated Coating Systems

5 Pages

-

My Tool, My Coating

6 Pages

-

New Quad Coatings

8 Pages

-

Coating of Large Chunks

4 Pages