Catalog excerpts

Engineered Honeycomb Solutions and Services Honeycomb Panels

Open the catalog to page 1

Plascore Honeycomb Panels Light, Strong, Tough, Cost-Effective Plascore Honeycomb Panels are a high-strength, lightweight material that provide efficient mechanical performance. Our lightweight panels are an excellent alternative to monolithic materials (e.g., solid aluminum, wood and steel) as well as panels with traditional core materials such as plywood, balsa, and foam. Available in a wide range of sheet sizes and facings, our honeycomb panels are designed for ease of use in many common applications and processes. They can be engineered to meet specific requirements for strength and...

Open the catalog to page 2

What is a Honeycomb Panel? FLEXURAL RESPONSE Two high-modulus and high-strength face sheets are adhesively bonded to Plascore Honeycomb. The result is a high-strength, lightweight structure that behaves much like an I-Beam. Balsa Foam SHEAR STRESS What Impacts Panel Stiffness? Bending stiffness is primarily based on three panel characteristics: SHEAR Area = Energy Absorption STRENGTH 1. Face Sheet Thickness 2. Face Sheet Modulus of Elasticity 3. Overall Panel Thickness SHEAR STRAIN % In simple terms, the core increases the flexural rigidity of a sandwich panel by effectively increasing the...

Open the catalog to page 3

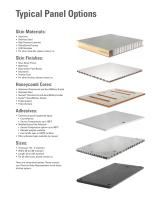

Typical Panel Options Skin Materials: • • • • • • Aluminum Stainless Steel High Pressure Laminate Glass/Epoxy Prepreg G10 Fiberglass For other materials, please contact us. Skin Finishes: • • • • • • Clear Epoxy Primer Mill Finish Bond and/or Paint Ready Decorative Powder Coat For other finishes, please contact us. Honeycomb Cores: • • • • • • Aluminum (Commercial and Aero/Military Grade) Stainless Steel Nomex® (Commercial and Aero/Military Grade) Kevlar® (Aero/Military Grade) Polypropylene Polycarbonate Adhesives: • Commercial grade toughened epoxy • Cost-effective • Service Temperatures...

Open the catalog to page 4

Panel Construction Considerations–Fabricating Co-Fabricated Edge Close-outs Machining/cutting can be done in most cases with basic wood working equipment such as a table saw, band saw, or router and carbide tipped tooling. DO NOT USE ANYTHING WITH A RECIPROCATING BLADE! Post-Fabricated Edge Close-outs Blind Fastening Potted Insert Thru Fastening Potted Insert Other Panel Construction Considerations–Joining Panel Joining can present a solution when a panel is too large to laminate in one piece. Internal honeycomb panel section used to join two panels

Open the catalog to page 5

Technical Data Designed to add value in OEM Product manufacturing, Plascore Honeycomb Panels are available cut to a custom size or shape, or in a standard sheet size of 48" x 96" in varying thicknesses. Note that all of these are open edge. PP4.0-86 PP Honeycomb core 4.0 pcf with 0.106" Luan Plywood skin AA5.2-95 Aluminium Honeycomb core 5.2 pcf with 0.015" Glass-Epoxy skin PP5.0-90 PP Honeycomb core 5.0 pcf with 0.014" Glass-Epoxy with Peel Ply film skin AA3.6-80 Aluminium Honeycomb core 3.6 pcf with 0.020" Aluminium skin FLATWISE TENSILE STRENGTH 1 CLIMBING DRUM 2 (PER UNIT WIDTH) .020"...

Open the catalog to page 6

HIGH STRENGTH SALT ENVIRONMENT FUEL ENVIRONMENT CHEMICAL RESISTANCE * * Detailed performance available upon request. STABILIZED COMPRESSIVE STRENGTH 3 lb/in2 FLEXURAL RIGIDITY 4 (PER UNIT WIDTH) 1 Data obtained through testing in accordance with ASTM C 297 2 Data obtained through testing in accordance with ASTM D 1781 with specimen widths of 3" 3 Data obtained through testing in accordance with ASTM C 365 4 Data obtained through testing in accordance with ASTM C393/C 393M-06 at a Four-Point, Quarter-Point Loading configuration and a space of 20", width 3", except 0.25"T @ 1.5"

Open the catalog to page 7

World Class Honeycomb Manufacturing, Technical Support and Service Plascore, Inc. is an ISO-9001 global manufacturer of Honeycomb cores and composite panels. In addition to our proprietary Honeycomb manufacturing process, our value-added capabilities include adhesive development, CNC machining, powder coating, welding, thermoset and thermoplastic laminating and assembly. We are dedicated to manufacturing competitive products with superior performance and on-time delivery. Plascore Honeycomb products are engineered to help reduce material and manufacturing costs, while making the end product...

Open the catalog to page 8All Plascore catalogs and technical brochures

-

Energy Absorption

8 Pages

-

Honeycomb Selector

1 Pages

-

Honeycomb Cores

2 Pages