Catalog excerpts

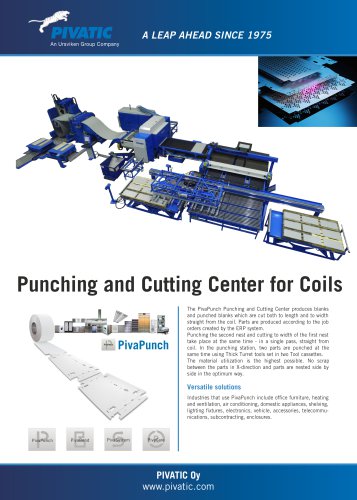

A LEAP AHEAD SINCE 1975 Punching and Cutting Center for Coils The PivaPunch Punching and Cutting Center produces blanks and punched blanks which are cut both to length and to width straight from the coil. Parts are produced according to the job orders created by the ERP system. Punching the second nest and cutting to width of the first nest take place at the same time - in a single pass, straight from coil. In the punching station, two parts are punched at the same time using Thick Turret tools set in two Tool cassettes. The material utilization is the highest possible. No scrap between the parts in X-direction and parts are nested side by side in the optimum way. Versatile solutions Industries that use PivaPunch include office furniture, heating and ventilation, air conditioning, domestic appliances, shelving, lighting fixtures, electronics, vehicle, accessories, telecommunications, subcontracting, enclosures.

Open the catalog to page 1

A LEAP AHEAD SINCE 1975 Bending Center The PivaBend concept brings cycle times for bending to the same level with punching times of work pieces for great total productivity. Our bender is based on the wing forming folding method, which makes it material friendly for pre-painted and stainless steel and aluminum. We’ll equip it for sections, panels or wrapper type work pieces based on your production requirements. PivaBend is more efficient than other sheet metal bending methods because the bender bends negative and positive bends set for each edge of the work piece, and the sides and the...

Open the catalog to page 2