Website:

Pinto Brasil

Website:

Pinto Brasil

Catalog excerpts

ASSEMBLY LINES PRODUCTIONS SYSTEMS

Open the catalog to page 1

Pinto Brasil builds modular Assembly Lines, especially designed for the production of electrical cables and assembly of mechanical/electric components for the automobile industry. Our Assembly Lines can be designed according to each client’s production requirements and specification for the required adaptability to each factory unit. System flexibility enables line cycle and speed adjustment, rapid reference change or the adjustment of associated peripherals, being able to operate according with two functional modules (continuous or sequential). Safety is one of our main concerns and that...

Open the catalog to page 2

DYNAMIC ASSEMBLY LINES 4

Open the catalog to page 3

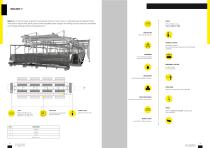

LAD is a line developed according to the start-stop principle for the assembly trays throughout the several working areas. Trays slide on tubular rails in two movement platforms: the higher working platform and the lower tray return platform. Line configuration ensures that components to use for assembly are provided frontally therefore assuring optimal ergonomics for operators. W WORKING AREA Operator movement area. Normal placement of production supporting structures. TRAYS STANDARD | 2.2m x 0.8m or 1.8m x 0.6m (please refer to the manufacturer for other dimensions). CONTROL SYSTEM...

Open the catalog to page 4

The Flat Line is constructed in accordance to the start-stop movement of the assembly trays throughout the several working areas. The sliding movement of the trays is made by lateral guides and the upper work platform and the lower trailing platform. This line is preferably used for large wiring, where there is a need for several trays for a single cabling. The identification of the different functions, through the use of LEDs and adjustments trays, gives a great flexibility of assembly. The Flat Line also has a web platform for monitoring and production management. LEVEL Positioning and...

Open the catalog to page 5

EQ (EFFICIENCY AND QUALITY) The E.Q. line was designed based on the start-stop principle. Product assembly is made by moving between working areas via a conveying canvas. This line offers great benefits from the ergonomic point of view as it allows the front loading of components by operators. In addition, and because area supply is made in line's posterior region, this equipment increases factory layout improvement. _TRAYS Trays of various sizes (depending on the size of the post). _CONTROL SYSTEM PRODUSI® Software. (for more information, please refer to the PRODUSI® catalogue). EMERGENCY...

Open the catalog to page 6

ROTARY ASSEMBLY LINES 12

Open the catalog to page 7

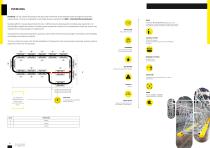

Rotary 7 is a line formed by a dynamic carousel-like structure. Trays move in a controlled way throughout the line. They slide on tubular rails, above ground, under regulable speed. Support and sliding structure, and trays are flexible and modular allowing prompt setup adjustments. WORKING AREA Operator movement area. TRAYS SIMPLE | DOUBLE (rotary) Length: Min. 2m | Max. 4.5m Width: Min. 0.7m | Max. 1.2m PRODUSI® Software. (for more information, please refer to the PRODUSI® catalogue). EMERGENCY SYSTEM EC DIRECTIVES. For the entire line. STRUCTURE Modular: from interlinked modules of 3 to...

Open the catalog to page 8

Rotary 8 | 18 is a line formed by a dynamic carousel-like structure. Trays move in a controlled way throughout the line, and are fixed in carts which move on the floor (guided by the line’s central structure). All elements are modular allowing prompt setup adjustments. WORKING AREA Operator movement area. TRAYS SIMPLE | DOUBLE (rotary) Length: Min. 2m | Max. 4.5m Width: Min. 0.7m | Max. 1.2m CONTROL SYSTEMS PRODUSI® Software. (for more information, please refer to the PRODUSI® catalogue). EMERGENCY SYSTEM EC DIRECTIVES. For the entire line. STRUCTURE Modular: from 6m with multiples of 3m...

Open the catalog to page 9

ROTARY 11 Rotary 11 is a line formed by a dynamic carousel-like structure. Trays move in a controlled over the defined working areas, by sliding on low-speed rails. Support and sliding structure is flexible and modular allowing prompt setup adjustments. PERIPHERAL Normal placement of production supporting structures. TRAYS SIMPLES | DOUBLE | TRIPLE (rotary) Quick Setup. Length: Min. 2m | Max. 4.5m Width: Min. 0.7m | Max. 1.2m CONTROL SYSTEM PRODUSI® Software. (for more information, please refer to the PRODUSI® catalogue). EMERGENCY SYSTEM EC DIRECTIVES. For the entire line.

Open the catalog to page 10

Rotary 19 is a line formed by a dynamic carousel-like structure. Trays move in a controlled way throughout the line, and are fixed in carts which move on the floor (guided by the line’s central structure). The traction zone is aerial and all elements are modular allowing prompt setup adjustments. TRAYS According to the set of specifications or client’s specifications. CONTROL SYSTEM PRODUSI® Software. (for more information, please refer to the PRODUSI® catalogue). EMERGENCY SYSTEM EC DIRECTIVES. For the entire line. STRUCTURE Modular: Modules 2,935m and 5,870m. SPEED Between 1m/min and...

Open the catalog to page 11

OVERHANG ASSEMBLY LINE CONVEYOR SYSTEM 22

Open the catalog to page 12

OVERHANG CONTENTS OVERHANG CONTENTS Overhang is a line created according to the start-stop movement of the assembly trays throughout the several working areas. The tray is suspended in and slides along an electrified rail (EMS – Electrified Monorail System). Several platforms may be placed along this line, in different levels, allowing perfect working area ergonomics. Its high flexibility enables the creation of working areas outside the central line for miscellaneous works like: rework; tray replacement and tray changes or modifications. Tray placement and positioning allows working on...

Open the catalog to page 13

DO YOU NEED A COSTUMIZED WIRE HARNESS ASSEMBLY LINE? LET’S TALK!

Open the catalog to page 14

PINTO BRASIL Rua de Pardelhas, nº 87, 4765-420 - Guardizela, Guimarães - Portugal | GPS 41.393133, -8.35799 (+351) 253 479 240 info@pintobrasil.pt www.pintobrasil.com A PINTO BRASIL GROUP COMPANY

Open the catalog to page 15All Pinto Brasil catalogs and technical brochures

-

PibraEasyform

15 Pages

-

Returnable Packaging & WIP

13 Pages

-

Racking and Shelvings

13 Pages

-

Automated Guided Vehicle

13 Pages